Air flow distribution plate for fluidized bed

A gas flow distribution plate, fluidized bed technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as disturbing gas flow stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

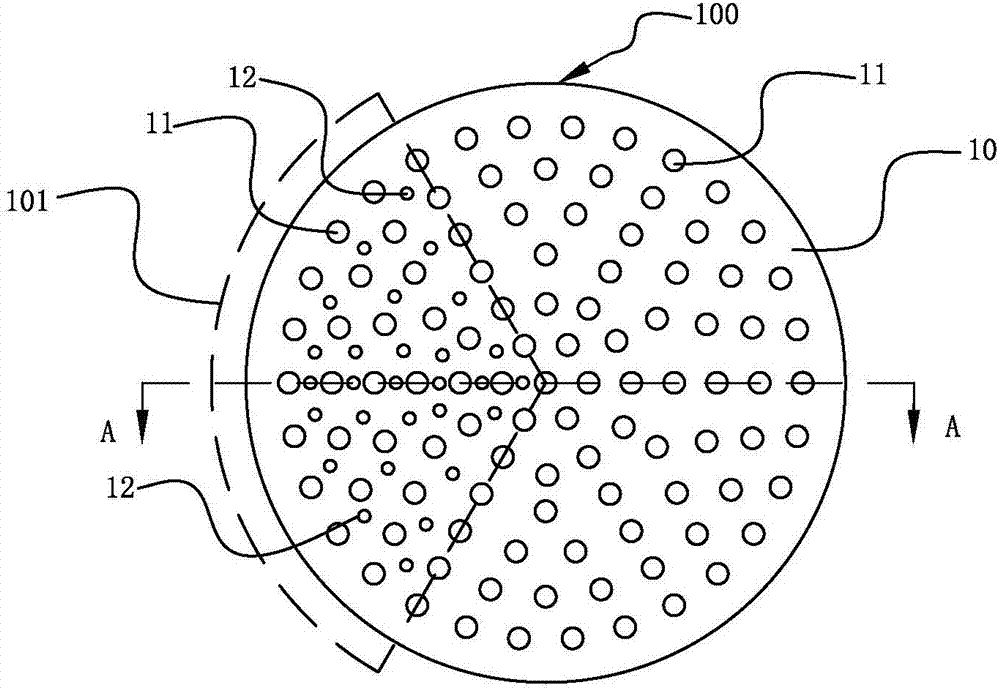

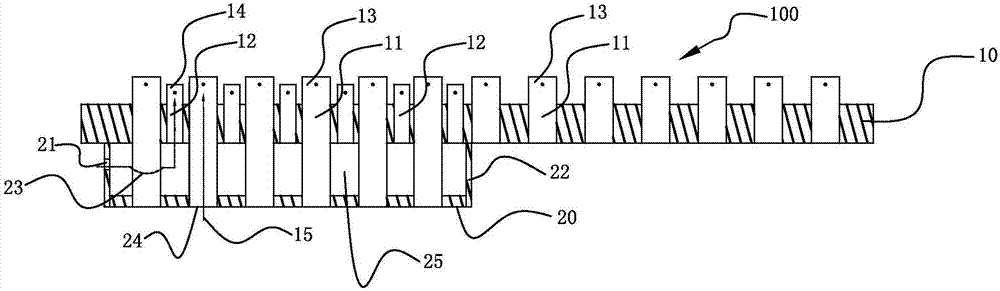

[0026] Please refer to figure 1 and figure 2 , the air flow distribution plate 100 for the fluidized bed of the present embodiment comprises a first base plate 10 and a second base plate 20, the second base plate 20 is arranged below the first base plate 10 in parallel, and the interval between the second base plate 20 and the first base plate 10 A cavity 25 is formed closed by the side wall 22 . The area of the second substrate 20 is equal to the area of the first substrate 10 , preferably, the area of the second substrate 20 is smaller than the area of the first substrate 10 .

[0027] The first base plate 10 is evenly distributed with many primary air passage holes 11 for maintaining the suspension of material particles and at least one secondary air passage hole 12 for blowing away the accumulated material agglomerated particles, and the outlet of the primary air passage hole 11 is provided with a A wind cap 13 and a secondary air cap 14 are provided at the outl...

Embodiment 2

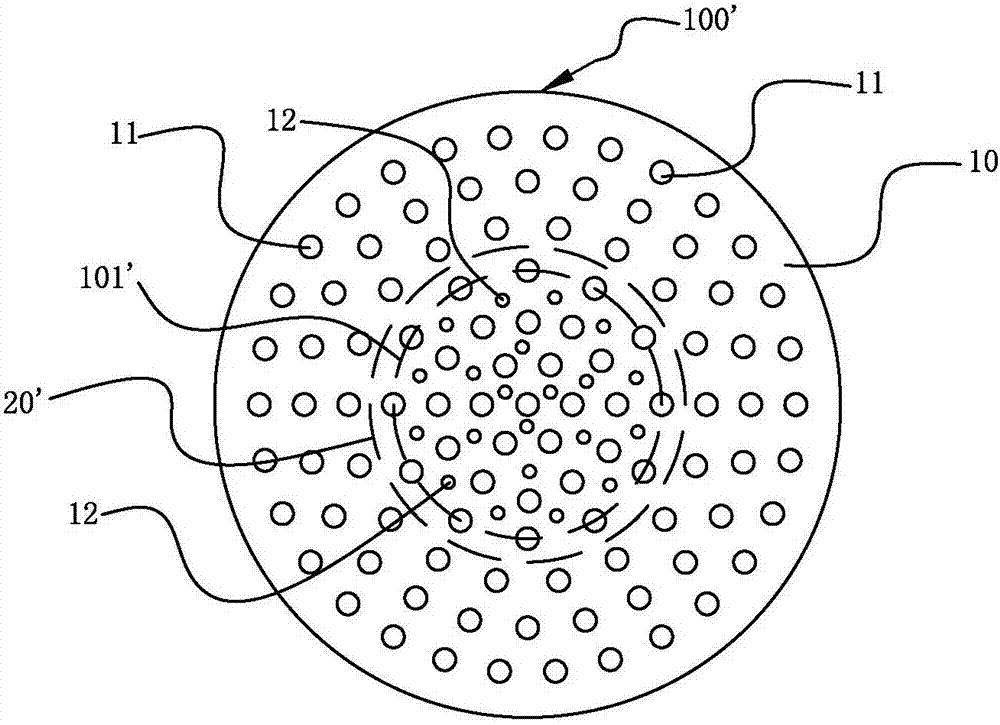

[0042] Please refer to image 3 The difference between the second embodiment and the first embodiment is that the stacking area 101' of the air distribution plate 100' for the fluidized bed is a circular area in the center, and the second substrate 20' corresponds to the stacking area 101' The second substrate 20 ′ is parallel to the bottom of the first substrate 10 , and the area of the second substrate 20 ′ is smaller than that of the first substrate 10 . In the second embodiment, the area where the material agglomerated particles of the air flow distribution plate 100' of the fluidized bed is easy to accumulate is mainly distributed in the central area, and the accumulation area 101' in the central area is set to blow off the accumulated material agglomeration The secondary air through holes 12 of the particles, and the opening ratio of the secondary air 23 of the first substrate 10 is smaller than the opening ratio of the primary air 15, so that the wind speed of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com