Beer or cider concentrate

A concentrate, cider technology, applied in the field of beer or cider, which can solve the problems of loss of flavor or aroma components, alcohol reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

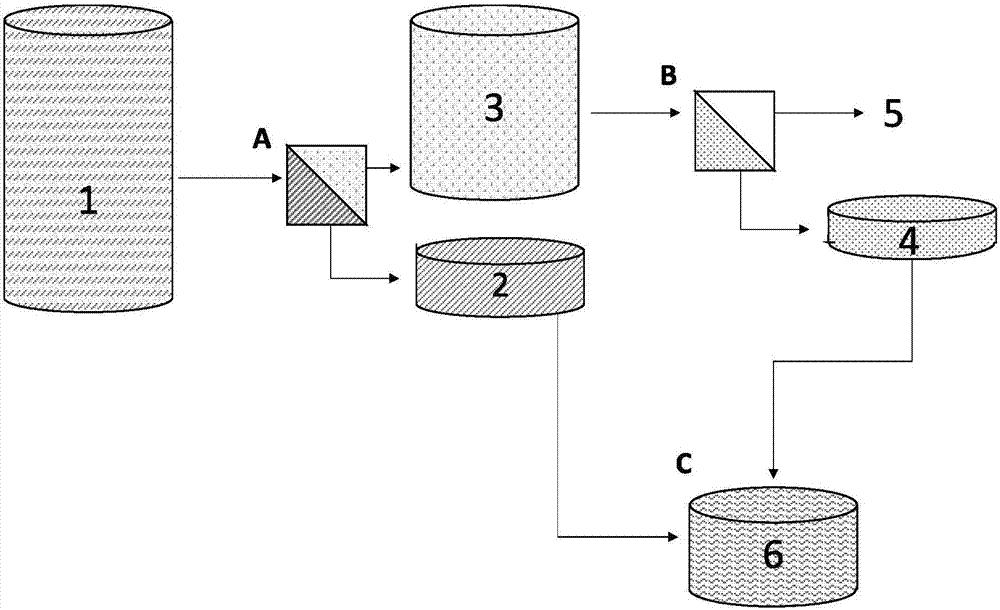

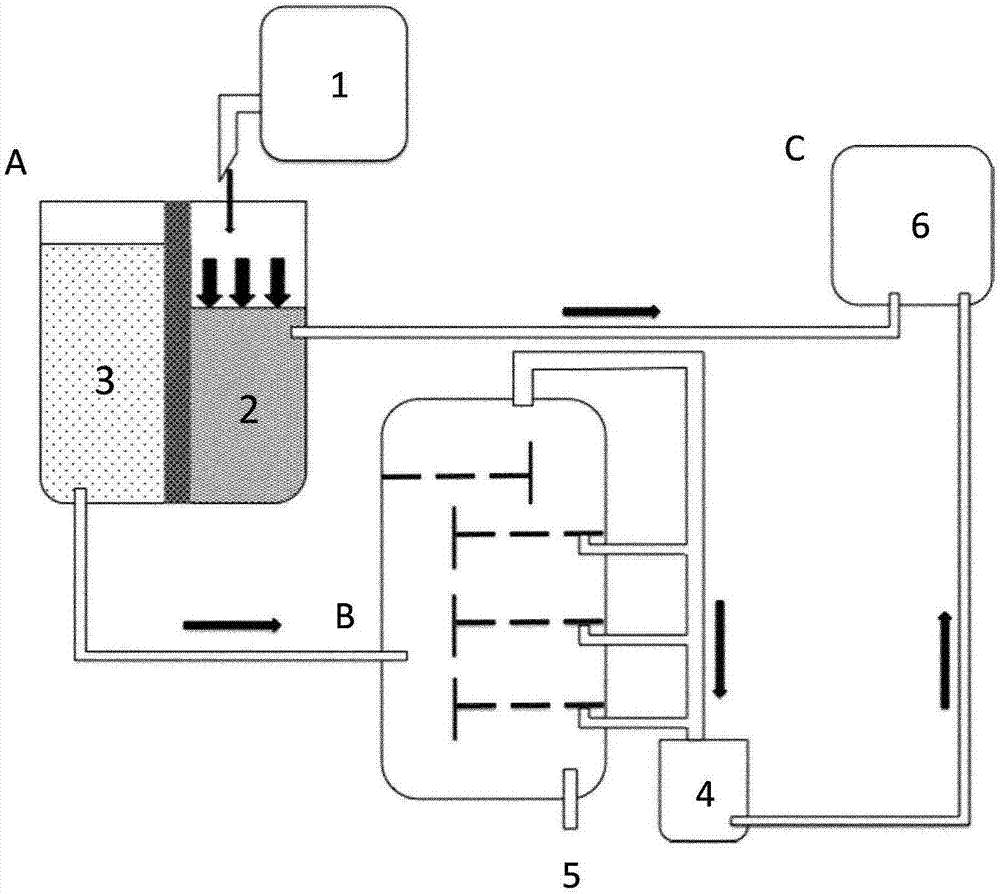

[0041] The present invention relates to a method for the preparation of an alcoholic beer concentrate, the method steps being the following steps:

[0042]

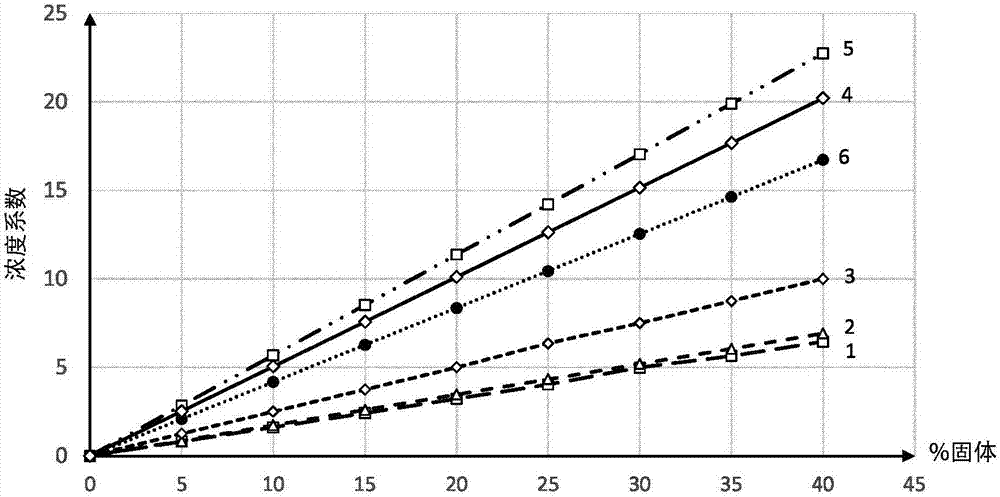

[0043] a) subjecting beer or cider (1) to a first concentration step including nanofiltration (A) or reverse osmosis to obtain a retentate (2) and a fraction (3) comprising alcohol and volatile flavor components, wherein all The retentate (2) is characterized by a concentration of non-filterable compounds equal to or higher than 20% (w / w), preferably 30% (w / w), as calculated from density measurements corrected for alcohol content, Most preferably 40% (w / w);

[0044] b) subjecting the fraction comprising alcohol and volatile flavor components to a next concentration step comprising freeze concentration, distillation, fractional distillation or reverse osmosis to obtain a concentrated fraction comprising alcohol and volatile flavor components and a residual fraction;

[0045] c) Combining the retentate from a) with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap