Separation device suitable for sheet materials of different materials

A sheet material and material technology, applied in the field of forging automatic production lines, can solve the problems of increasing the labor load of the staff, affecting the production efficiency, and consuming a lot of manpower, and achieves the effects of good splitting effect, simple structure, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

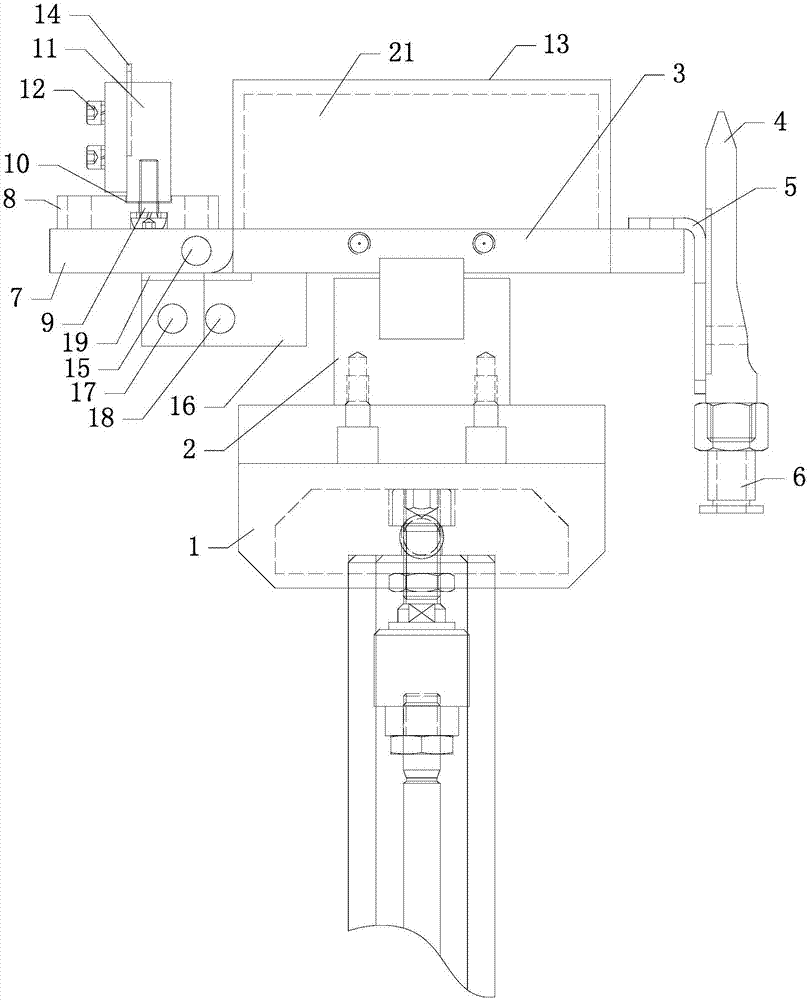

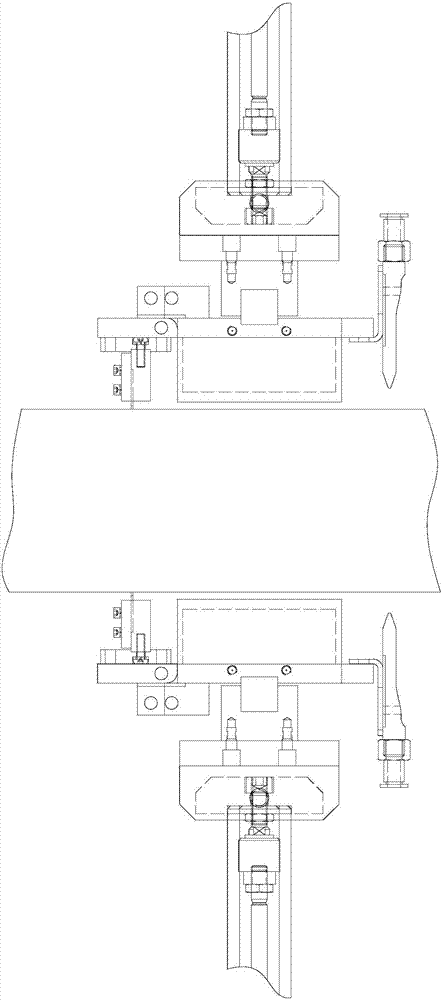

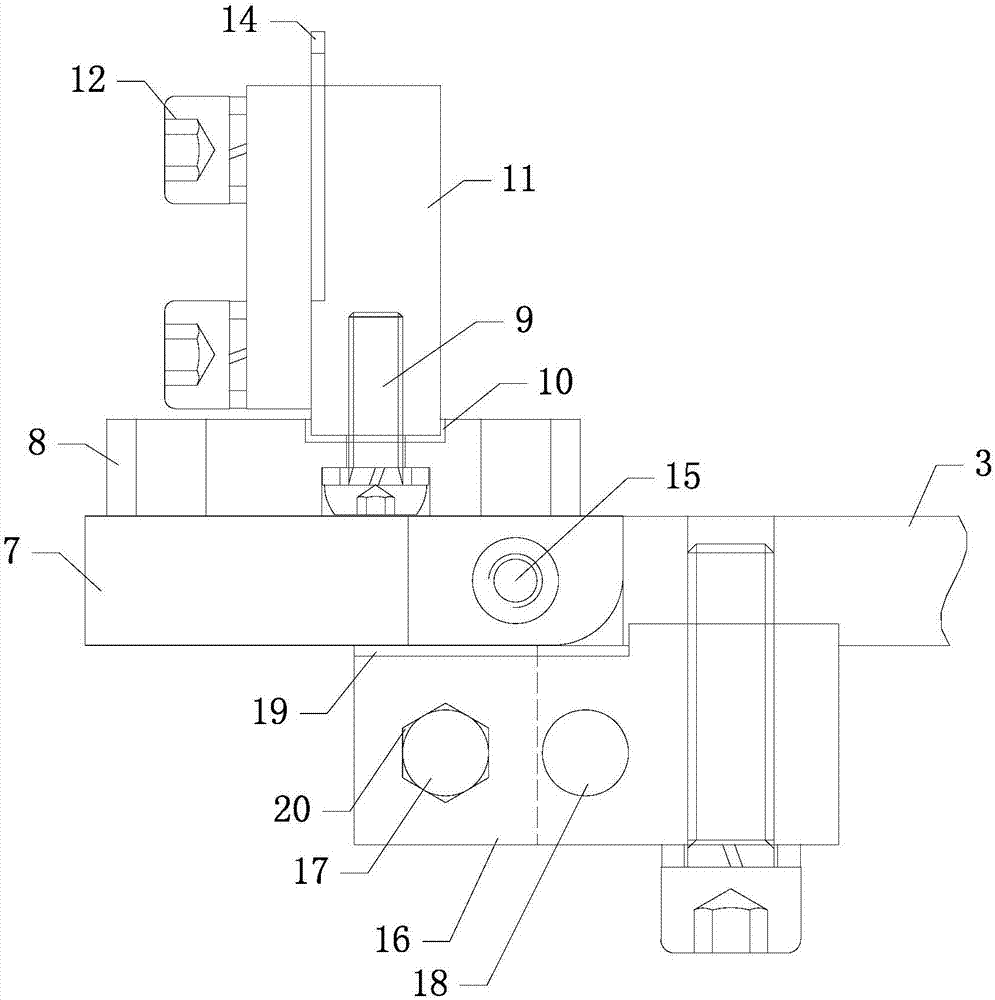

[0020] In order to clearly illustrate the technical characteristics of this solution, the following describes the present invention in detail through specific implementations and in conjunction with the accompanying drawings.

[0021] Such as Figure 1-4 As shown in the figure, a splitting device suitable for sheets of different materials includes a fixing frame 1, a connecting block 2 is fixedly connected to the end of the fixing frame 1 close to the sheet by bolts, and the inner end of the connecting block 2 is fixedly connected A fixed plate 3, one side of the inner end surface of the fixed plate 3 is provided with an air source splitting device, and a stainless steel plate splitting device is provided on the inner end of the fixed plate 3 on the left side of the air source splitting device. A magnetic splitting device is provided on the inner end surface of the fixing plate 3 between the splitting device and the air source splitting device; the air source splitting device inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com