Intermittent Motion Mechanism and Its Molding Technology of Unilateral Toothless Row

A kinematic mechanism and molding technology, applied in metal processing, transportation and packaging, object supply, etc., can solve the problem of increasing the load and motion inertia of the intermittent transmission mechanism, affecting the processing accuracy and yield of die-cut paper products, and failing to improve production efficiency, etc. problems, to achieve the effect of improving operating speed and production efficiency, improving die-cutting precision and yield, and optimizing and simplifying equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

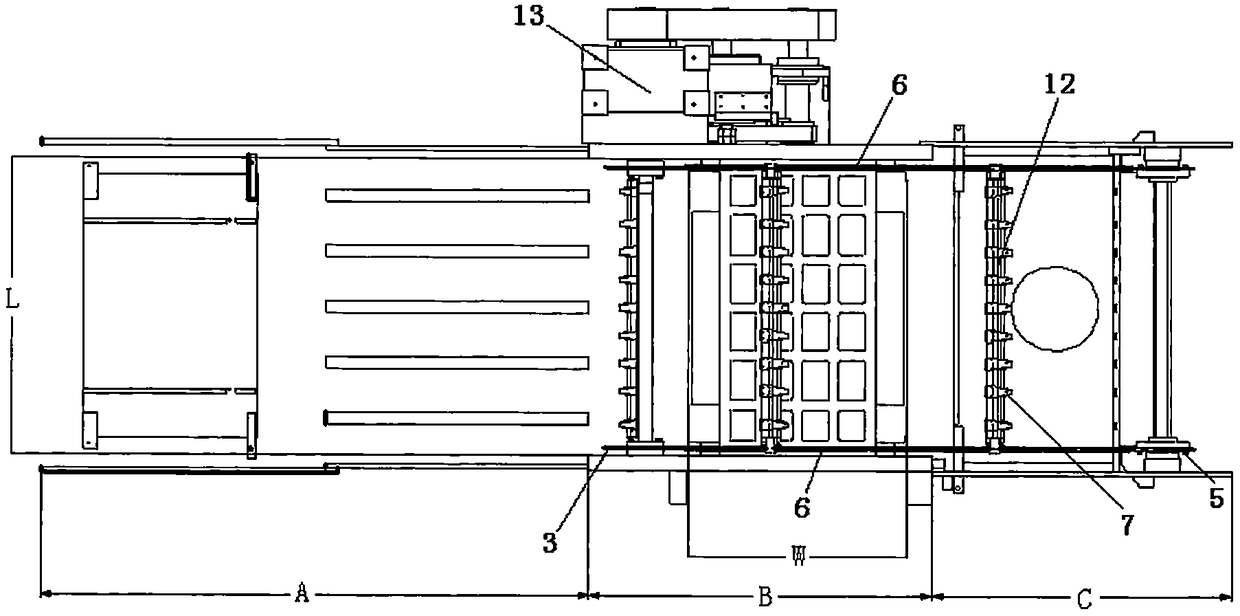

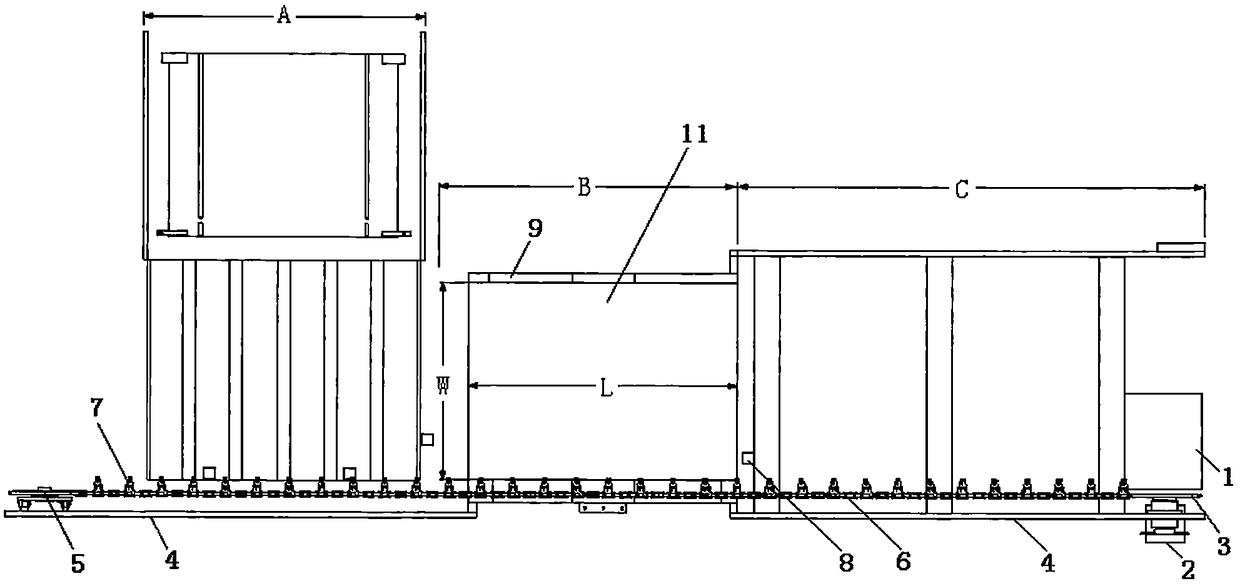

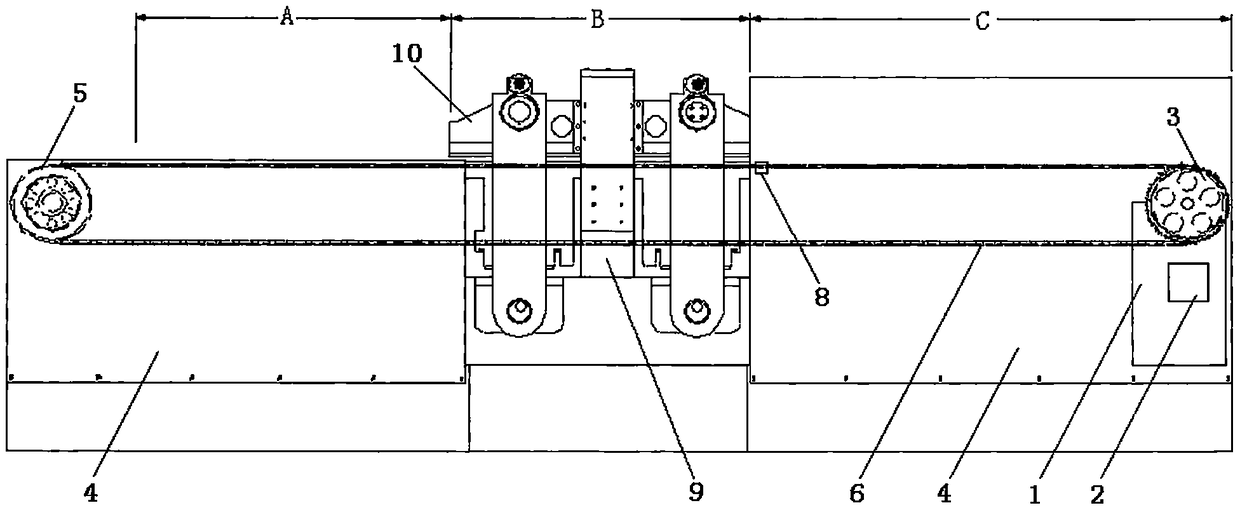

[0014] Such as figure 2 , 3 As shown, the technical scheme of the unilateral toothless row intermittent motion mechanism is, including servo motion control system 1, servo motor 2, driving sprocket 3, driven sprocket 5, chain 6, gripper teeth 7, photoelectric detection switch 8 , the servo motion control system 1, the servo motor 2, and a driving sprocket 3 are respectively arranged on the frame wallboard 4 on the rear side of the complete machine. The driving sprocket 3 is driven by the power of the servo motor 2, and a driven sprocket 5. It is set on the frame wallboard 4 on the front side of the whole machine. A chain 6 is connected to the driving sprocket 3 and the driven sprocket 5. Several gripper teeth 7 are fixed on the chain 6. The photoelectric detection switch 8 is arranged on fixed platform 9 one sides.

[0015] The molding process of the intermittent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com