Automatic cutting and packaging integrated machine for XPS extruded sheets

An extruded board, automatic technology, used in packaging, bundling machinery parts, metal processing and other directions, can solve the problems of poor dimensional stability, a lot of manual work, difficult for workers to tidy up, and achieve neat product size and beautiful packaging. Tight and simple structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

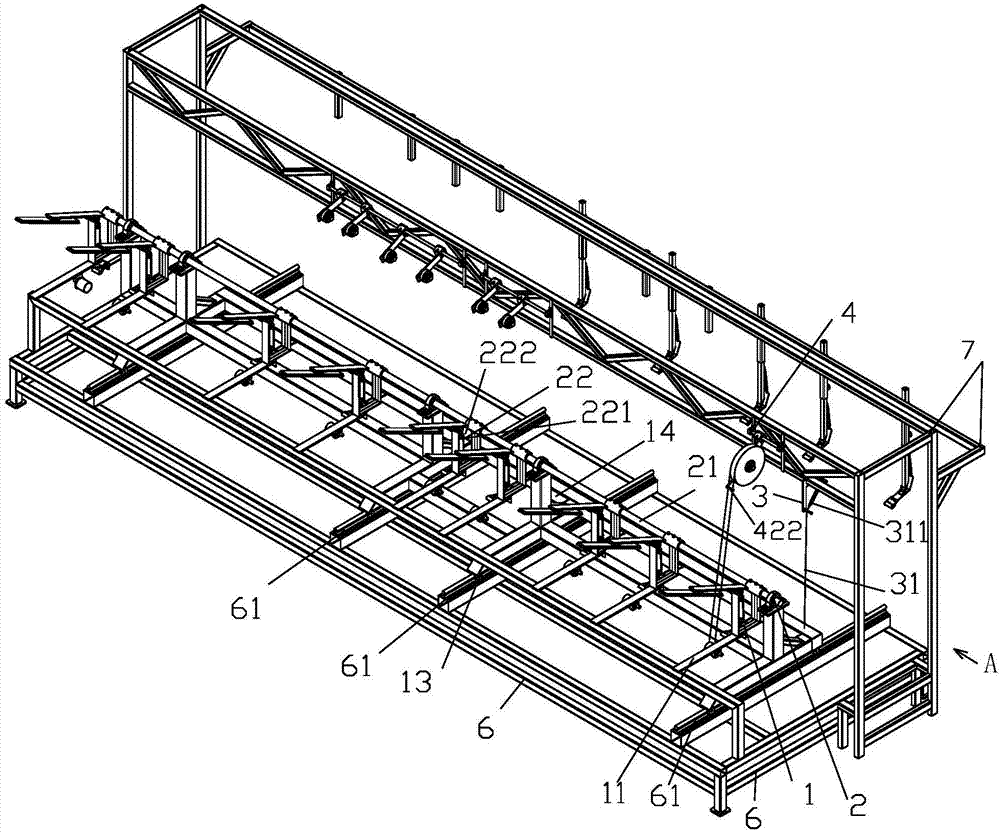

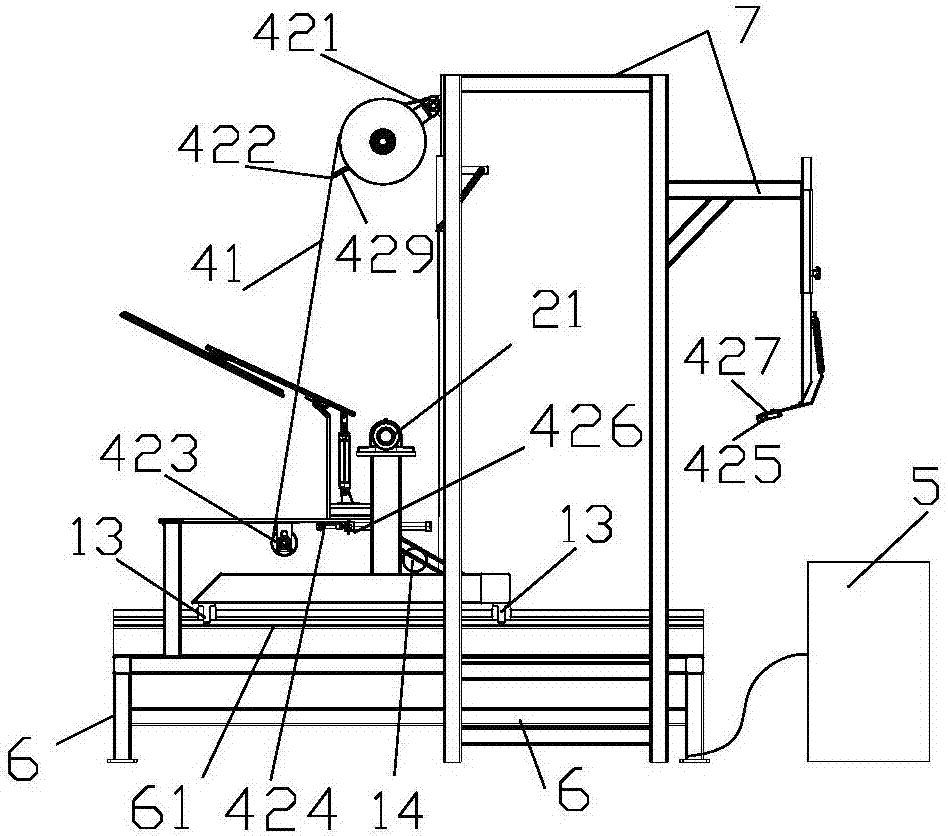

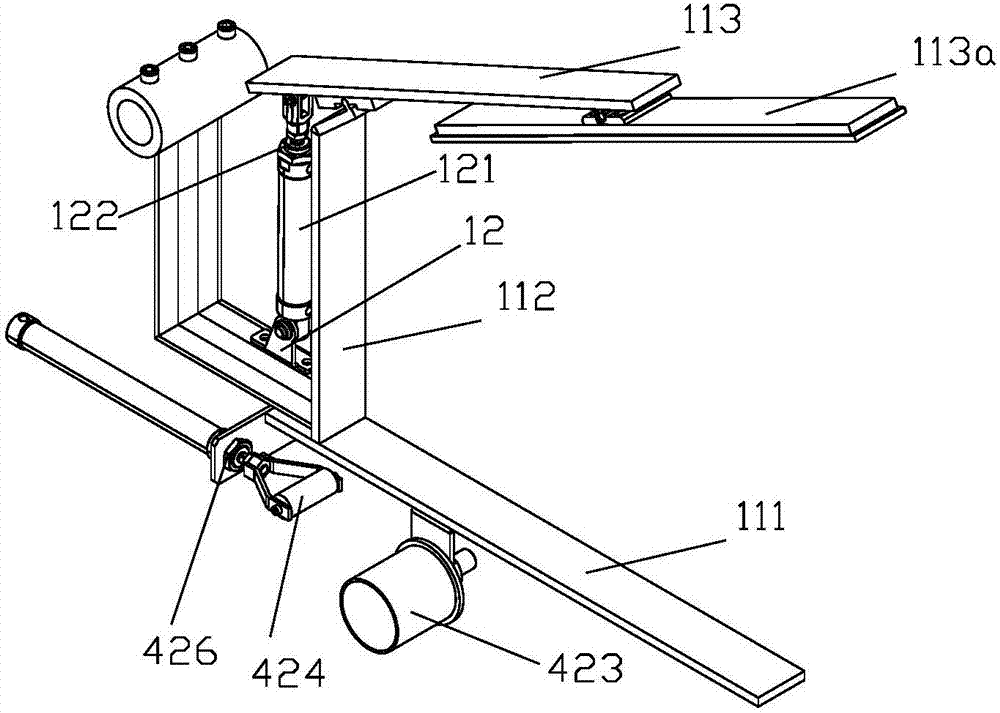

[0027] Embodiment 1: a kind of automatic XPS extruded board cutting and packaging all-in-one machine, such as figure 1 and figure 2As shown, it includes a (reciprocatingly movable) manipulator assembly with multiple parallel manipulators, a turning mechanism for turning over the manipulator, a cutting resistance wire assembly with multiple cutting resistance wires, and a multi-packing belt. Packing components, in this embodiment, the packing tape is a packing transparent tape, which can be firmly pasted on the surface and side of the XPS extruded board, and also includes a controller, which can be a manual or an automatic controller controlled by a program. An example is a manual controller, the manipulator assembly also includes a clamping and releasing mechanism, the power of which is provided by the first air cylinder, and the manipulator controls the clamping and releasing mechanism through the controller to clamp multiple overlapping pieces neatly XPS extruded board, th...

Embodiment 2

[0034] Embodiment 2: as Figure 5 , an automatic XPS extruded board cutting and packaging all-in-one machine, the same as embodiment 1, the difference is that the controller of the all-in-one machine is specifically a PLC controller, which is an automatic controller controlled by a program, and the PLC controller The control sequence of the automatic control program is designed as follows: while the manipulator clamps multiple overlapping XPS extruded boards, the packing transparent tape is pasted on the bottom surface of the bottom XPS extruded board and the overlapping XPS extruded boards are bonded together. One side of the vertical arm, and then the manipulator flips the overlapping XPS extruded boards by 90 degrees, and pastes the surface of the top XPS extruded board while turning over the packing transparent tape, and then the manipulator moves horizontally, and enters the vertical cutting at the same time During the resistance wire cutting process, multiple overlapped ...

Embodiment 3

[0035] Embodiment 3: An automatic XPS extruded board cutting and packaging integrated machine, the same as Embodiment 2, the difference is that the integrated machine also includes a feeding trough provided with a horizontal pusher plate, which is used for The plane of the feeding trough where the XPS extruded boards are placed is parallel to and adjacent to the surface formed by the horizontal arms of multiple manipulators. The automatic program of the PLC controller controls the longitudinal overlapping of multiple pieces of XPS extruded boards. When the number of plastic plates reaches the set number, the horizontal push plate pushes them neatly from the feeding trough into multiple manipulators at the same time. The bottom surface of a piece of XPS extruded board at the bottom achieves the purpose of overlapping neatly with multiple XPS extruded boards. See figure 1 , the feeding trough is not shown in the figure, actually viewed from direction A, the feeding trough is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com