Pneumatic tire

A technology for pneumatic tires and treads, which is applied to the reinforcement layers, tire parts, tires, etc. of pneumatic tires, can solve the problems of not yet established convex edges and concave edges, rising manufacturing costs, etc., so as to prevent the generation of convex edges and concave edges. The effect of suppressing the increase in manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

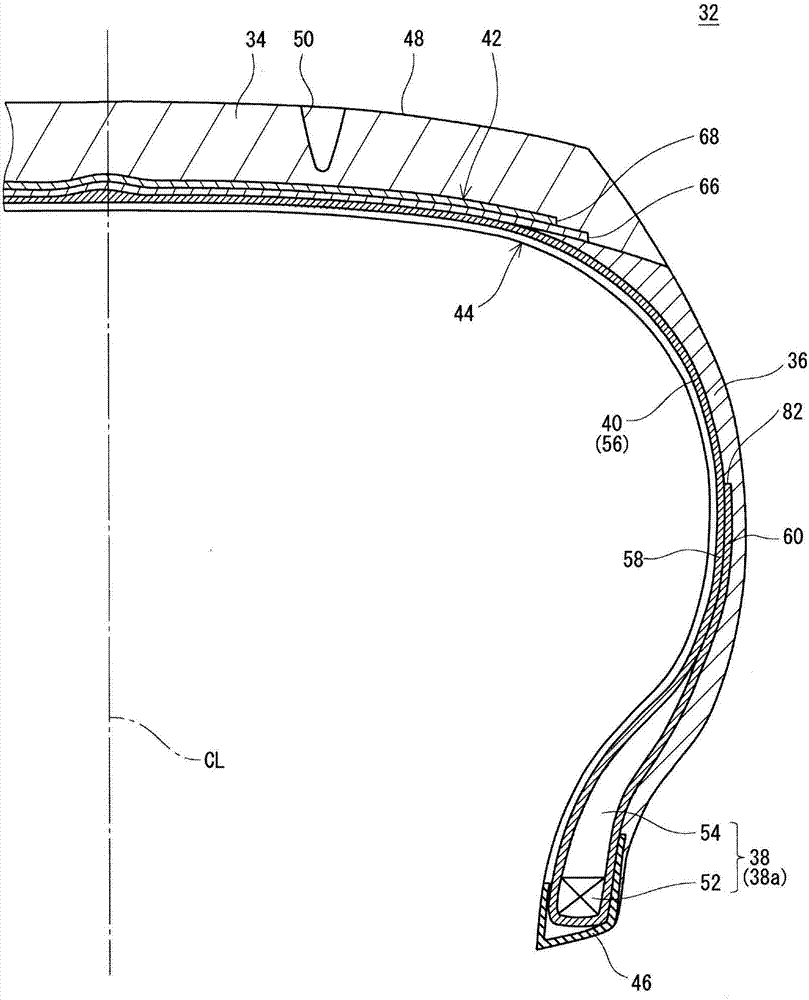

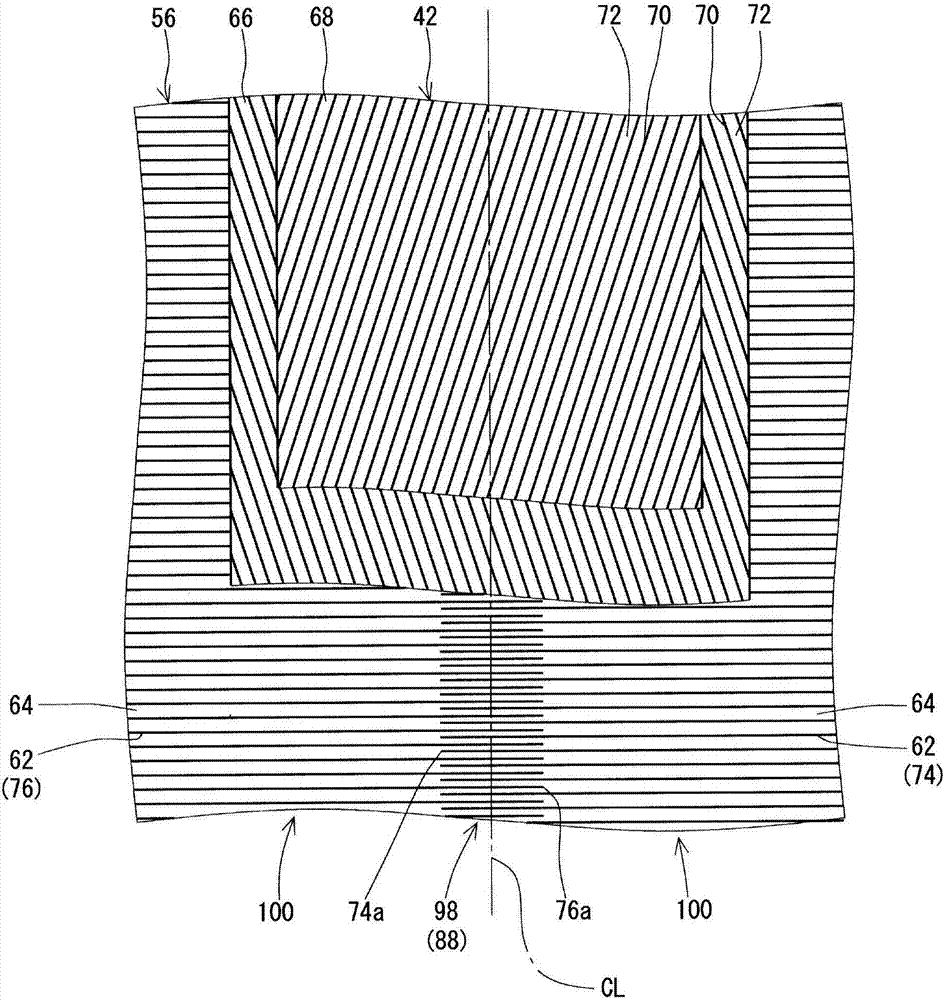

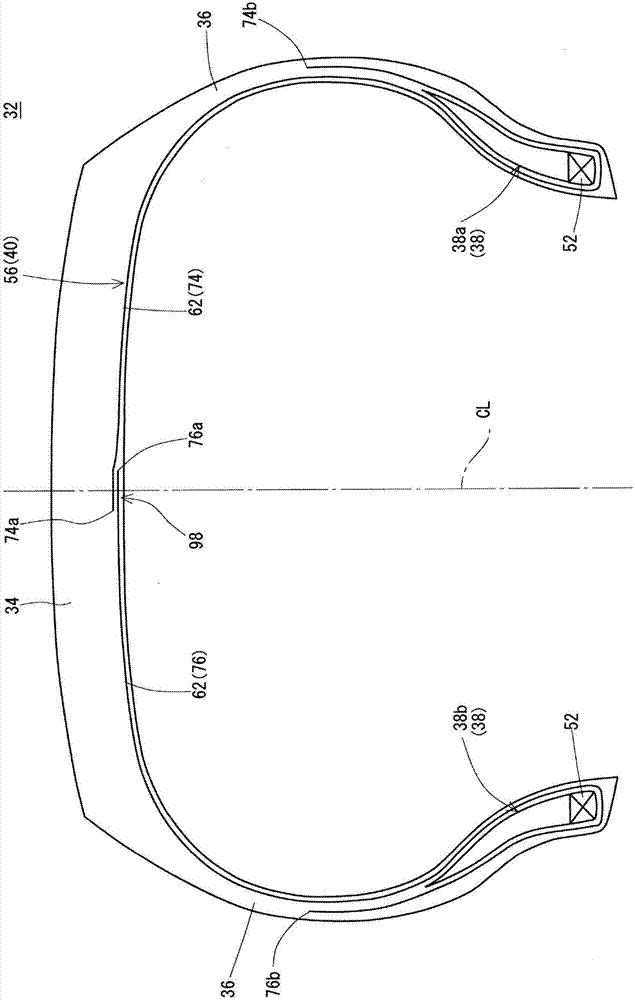

[0103] make Figure 1-3 tires shown. The size of this tire is 155 / 65R13. In the production of this tire, the first sheet and the second sheet are used to form a sheet-shaped carcass ply. The width AL of the longitudinal joint portion in this carcass ply was 10 mm. In this carcass ply, the leading edge and the trailing edge are formed to extend in the width direction without being inclined with respect to the width direction. This is noted as "Width" in the column of processing of the edge.

Embodiment 2-7

[0109] The width AL of the longitudinal joint portion was as shown in Table 1 below, and the other was the same as that of Example 1, thereby producing tires of Examples 2-7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com