Vacuum processing device, method for moving substrate and alignment mask, alignment method, and film forming method

A vacuum processing device and mask technology, which is applied to lighting devices, gaseous chemical plating, coatings, etc., can solve the problems of longer downtime, manual operation, and difficulty in particle management, so as to improve downtime and reduce particle size. Ease of management and reduction of work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

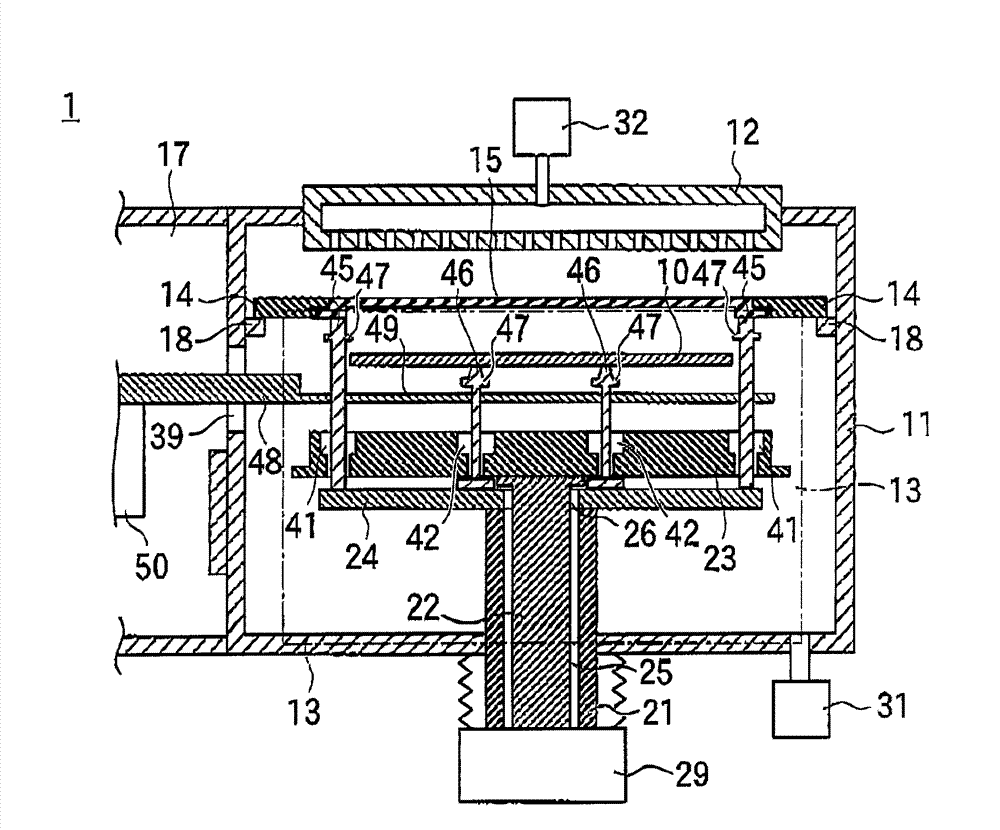

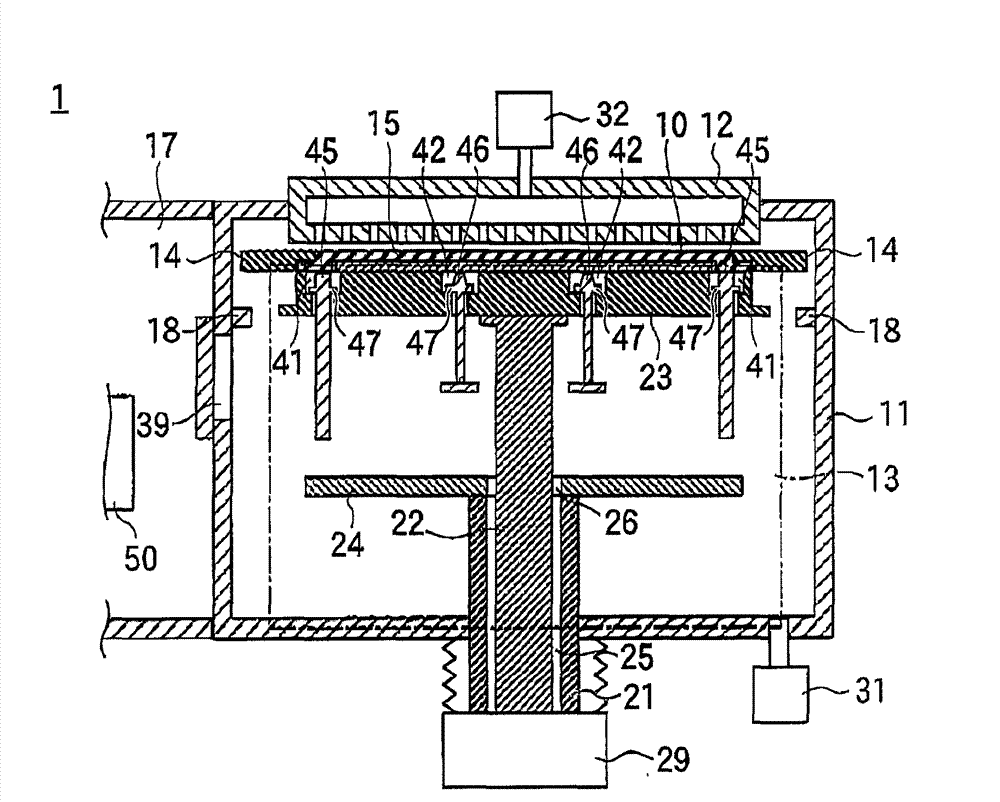

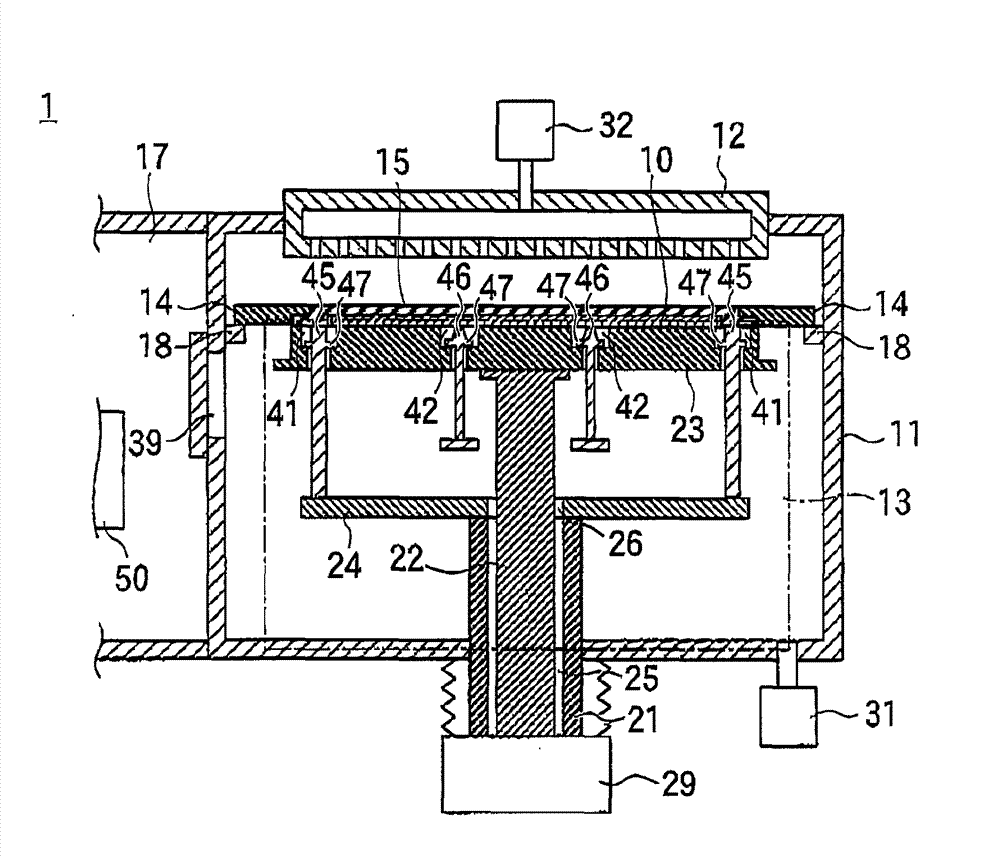

[0054] Reference numeral 1 denotes a vacuum processing apparatus of an example of the present invention.

[0055] First, the structure of the vacuum processing apparatus 1 will be described.

[0056] Referring to FIG. 1 , the vacuum processing apparatus 1 has a vacuum chamber 11, a gas introduction device 12 composed of shower nozzles is disposed on the ceiling side of the vacuum chamber 11, and a processing table 13 is disposed directly below it.

[0057] The vacuum tank 11 is connected to a vacuum exhaust system 31 , and the gas introduction device 12 is connected to a raw material gas introduction system 32 . While operating the vacuum evacuation system 31 to evacuate the inside of the vacuum chamber 11, raw material gases and reaction gases, which are material gases for thin film formation, are supplied from the raw material gas introduction system 32 to the gas introduction device 12. The device 12 distributes source gas and reaction gas into the vacuum chamber 11 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com