A sorting device for winter jujube

A sorting device, technology of winter jujube, applied in solid separation, sieve, grid, etc., can solve the problems of low sorting efficiency, high cost, slow manual sorting speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is realized through the following technical solutions:

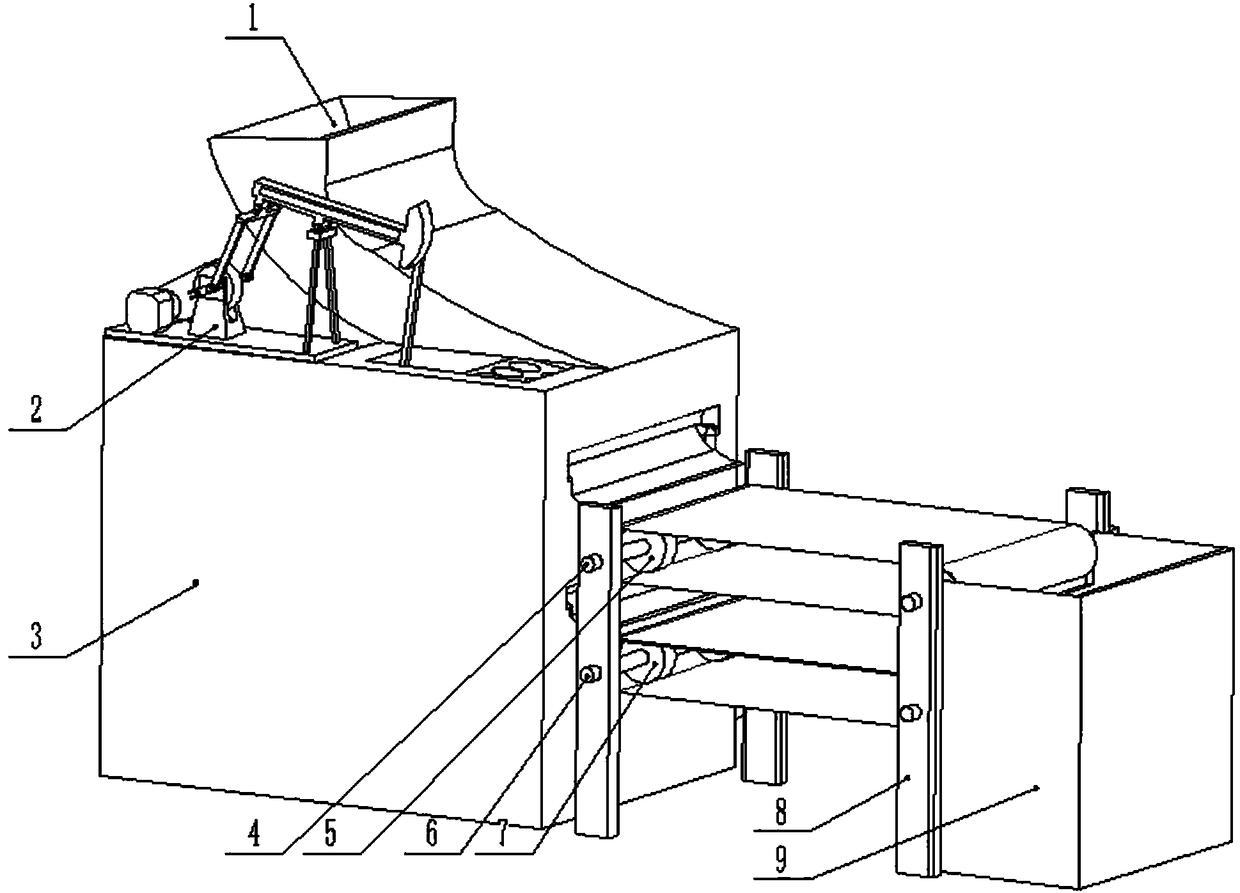

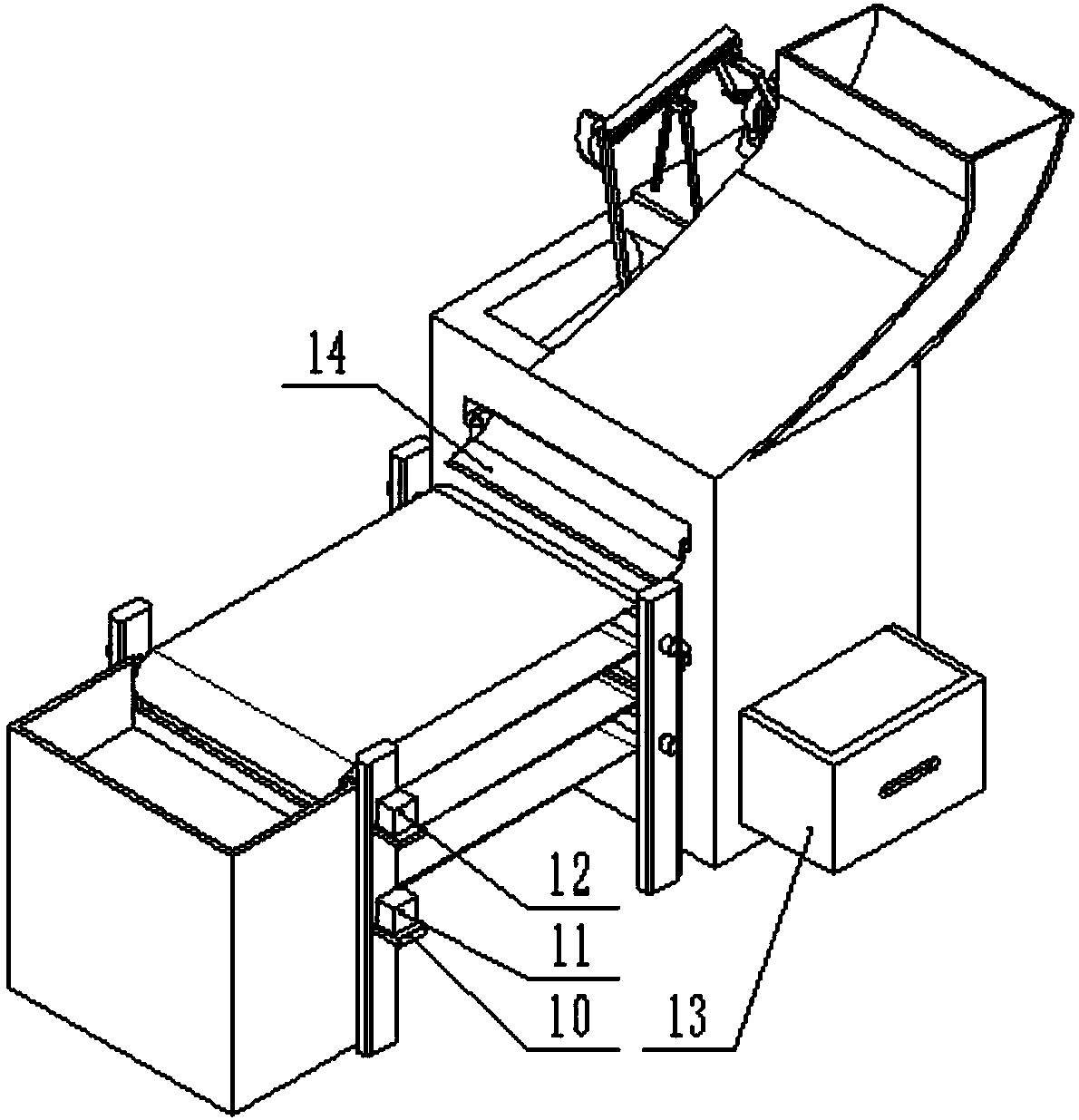

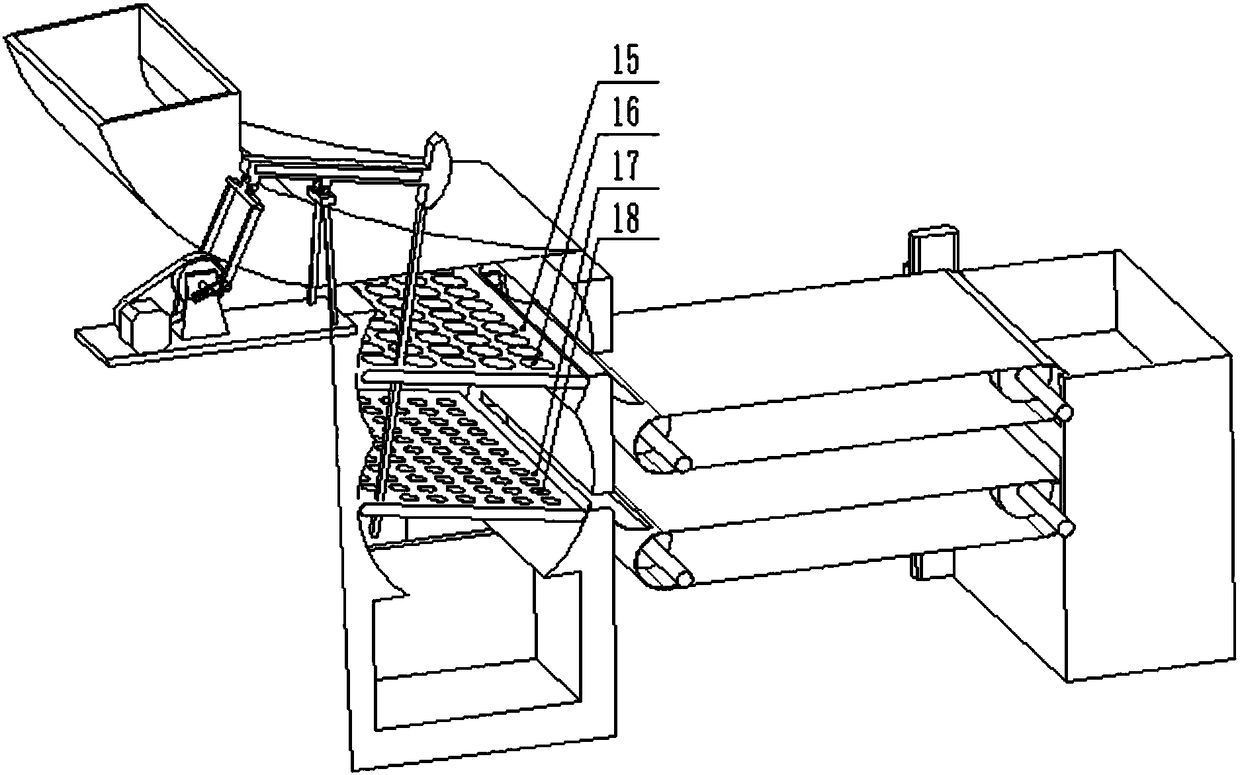

[0020] A winter jujube sorting device, comprising a feed port 1, a vibrating device 2, a body 3, a first rotating shaft 4, a first rotating shaft roller 5, a second rotating shaft 6, a second rotating shaft roller 7, legs 8, Box 9, motor support 10, first motor 11, second motor 12, waste box 13, side plate 14, first screening plate 15, large round hole 16, second screening plate 17, small round hole 18, third rotation Shaft 19, the third rotating shaft roller 20, the second conveyor belt 21, the fourth rotating shaft 22, the fourth rotating shaft roller 23 and the first conveyor belt 24, the feed inlet 1 is installed on the top of the body 3 and connected with the body 3 inside In communication, the vibrating device 2 is installed on the side of the feed port 1, the first rotating shaft 4 is installed on the leg 8, and two of the first rotating shaft rollers 5 are distributed on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com