Slag dry granulation waste heat recovery device with self-regulating and anti-slagging functions

A waste heat recovery device and dry granulation technology, applied in recycling technology, waste heat treatment, lighting and heating equipment, etc., can solve the problems of insufficient particle quality, unsatisfactory granulation effect, and aggravation of slag wool slag, etc. Achieve the effect of reducing the probability of sticking to the wall surface, accelerating the cooling and solidification process, and accelerating the solidification of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

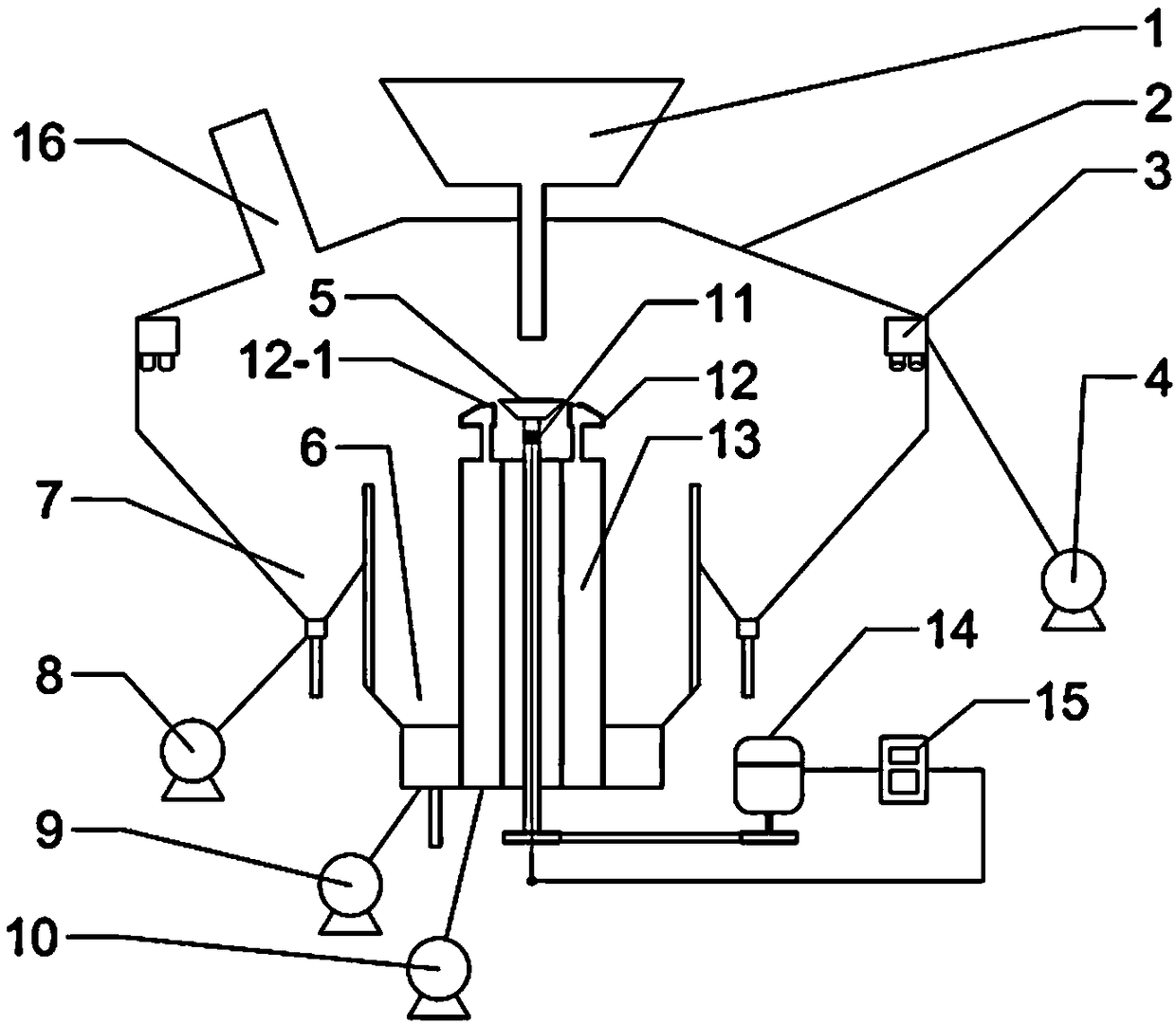

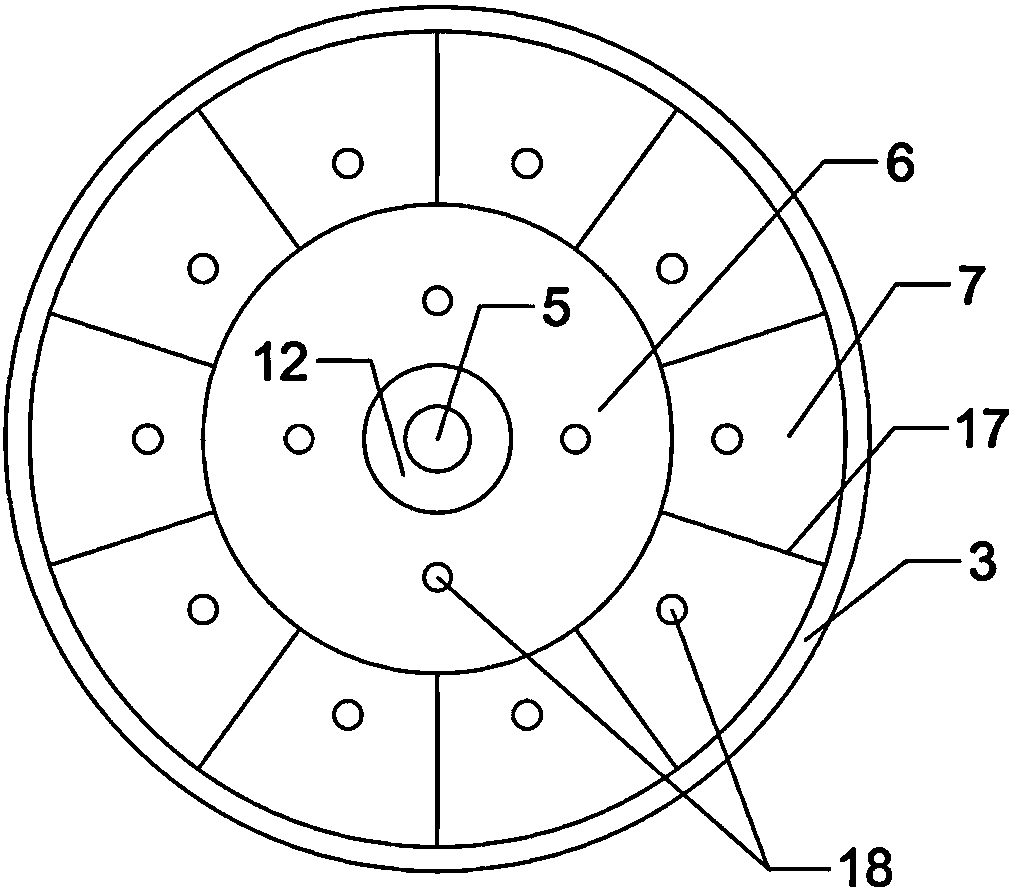

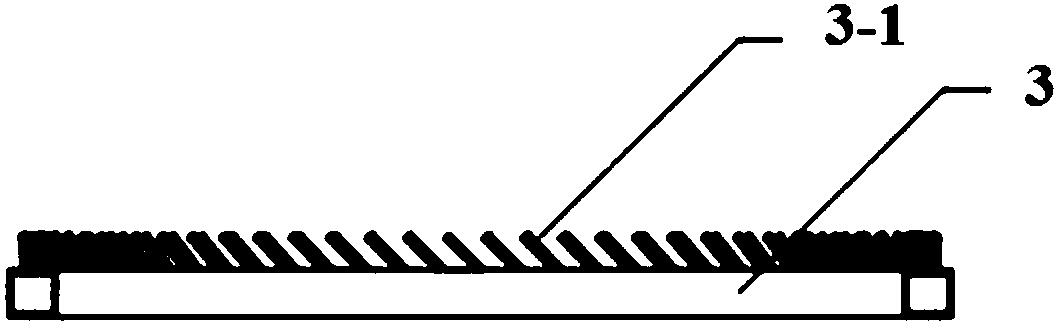

[0016] see Figure 1 to Figure 6 , a slag dry granulation waste heat recovery device with self-regulation and anti-slagging functions, including a slag tundish 1 and a granulation chamber 2, the slag tundish 1 and the granulation chamber 2 are connected by a slag inlet pipe; The top of the granulation chamber 2 is provided with an air outlet 16, and a centrifugal granulator 5 is arranged inside the granulation chamber 2, and the centrifugal granulator 5 is located below the slag inlet pipe; the top of the centrifugal granulator 5 is provided with a rotor , the rotor is rotated by a variable frequency motor 14; a pressure sensor 11 is installed on the bottom of the rotor, and the pressure sensor 11 feeds back the pressure signal to the speed controller 15 to adjust the speed of the frequency conversion motor 14; the outside of the centrifugal granulator 5 is provided with Air-quenching air chamber 13; the outside of the rotor is provided with an air-quenching air ring 12, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com