A bending degree inspection and sorting device for straight pipe products

A sorting device and curvature technology, applied in electromagnetic measurement devices, electric/magnetic profile/curvature measurement, etc., which can solve the problems of user quality complaints, labor intensity of workers, misjudgment and missed inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

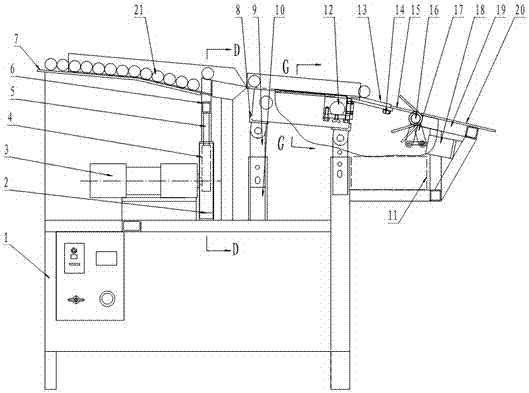

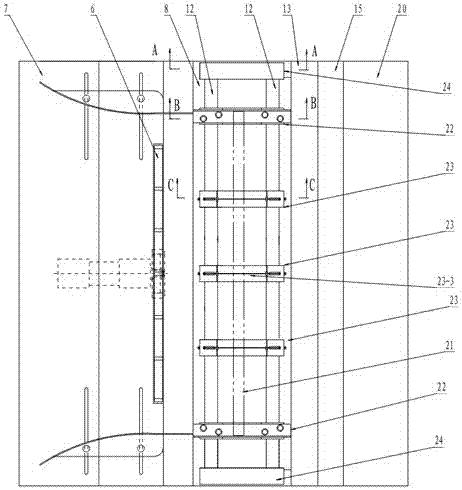

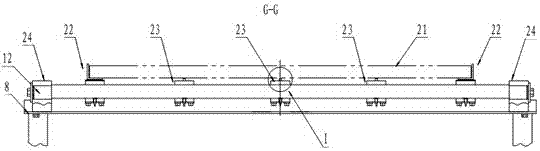

[0025] see figure 1 , figure 2 , the present invention includes a frame 1 and a feeding part, a detection part and a sorting part arranged on the frame sequentially from the front (left) to the rear (right). Straight tube product pieces 21 that need to be tested for bending are placed on the loading platform 7 provided at an inclination in the loading part. The straight tube products that enter the detection part still rely on gravity to roll. During the rolling process, the straight tube products with qualified bending degree do not touch the conductive wire 23-3 on the detection assembly 23, and roll into The next process: straight tube products with unqualified curvature touch the conductive wire on the detection component, the connected circuit sends out an electrical signal, and the flipper cylinder moves to open the flipper, so that straight tube products with unqualified curvature fall into unqualified products The collection box 11 triggers the proximity switch when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com