Factory pneumatic panax notoginseng seeder

An air-suction, factory-like technology, applied in the field of agricultural machinery, can solve problems such as the inability to realize standardization of factory-style operations, low production efficiency and operation quality, and unfavorable production of high-quality Panax notoginseng, so as to improve the level of Panax notoginseng planting and operation Good quality, the effect of improving quality and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

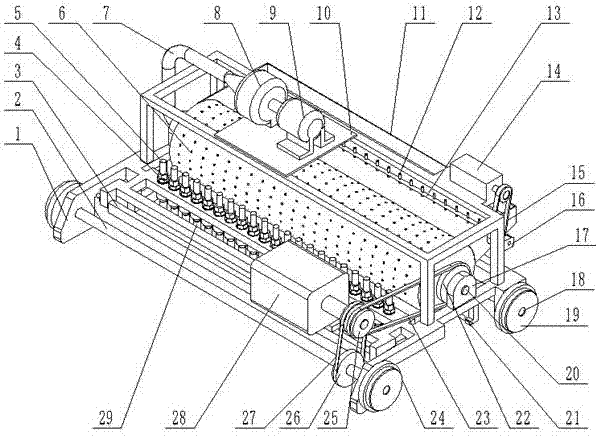

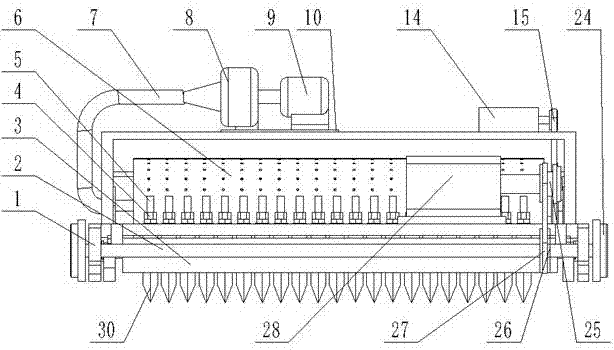

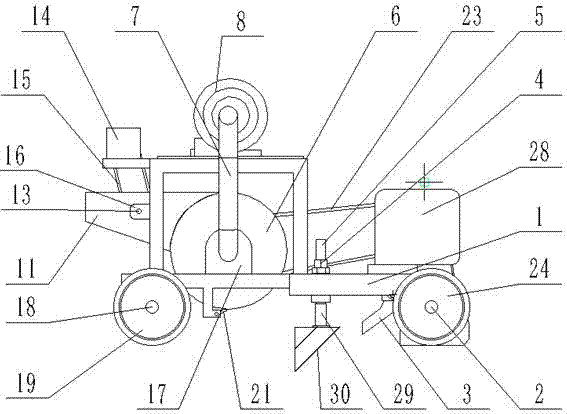

[0026] Example 1: as Figure 1-4 As shown, a factory air-suction notoginseng seeder includes a frame 1, a front axle 2, a moldboard 3, an adjustment nut 4, a screw 5, a seed meter 6, an air pipe 7, a fan 8, and a fan drive motor 9. Seed box 11, stirring teeth 12, stirring shaft 13, stirring shaft driving motor 14, stirring shaft driving mechanism 15, bearing 16, seed meter support 17, rear wheel shaft 18, rear wheel 19, hollow shaft 20, seed scraping Plate 21, seed meter drive sprocket 22, seed meter chain 23, front wheel 24, double sprocket 25, front axle sprocket 26, front wheel chain 27, drive motor 28, spring 29, ditch opener 30;

[0027] Described front axle 2 is installed in the front end installation hole of frame 1, and two front wheels 24 are installed in the left and right sides of front axle 2 respectively; Rear axle 18 is installed in the rear end installation hole of frame 1, two The rear wheels 19 are respectively installed on the left and right sides of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com