Precision seeding device for beans

A technology for precise sowing and mass seeding, which is applied in the field of precision seeding devices for beans, can solve the problems of low sowing accuracy, limited use site, and high use cost, achieves improved speed and accuracy, and avoids multicast and missed sowing , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

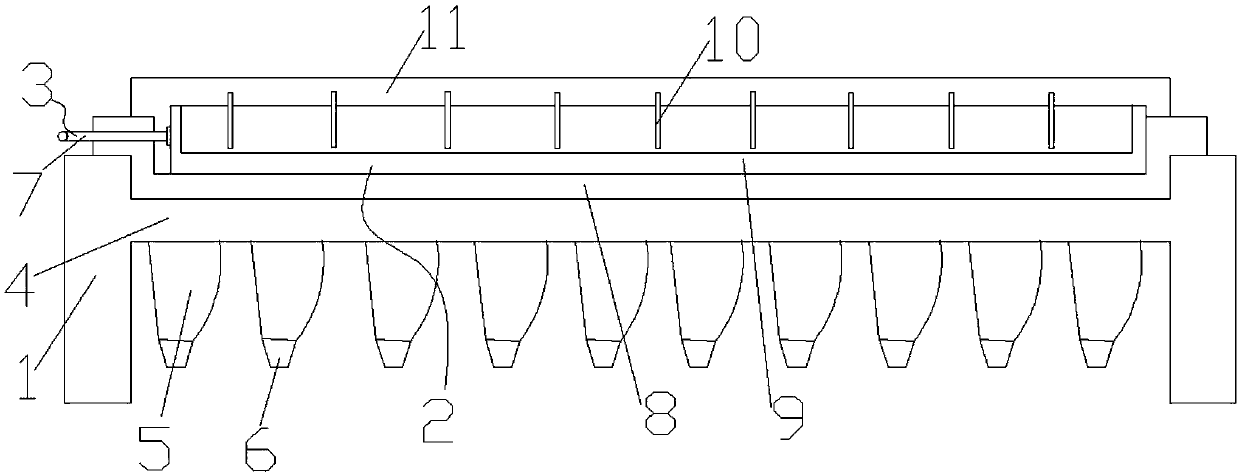

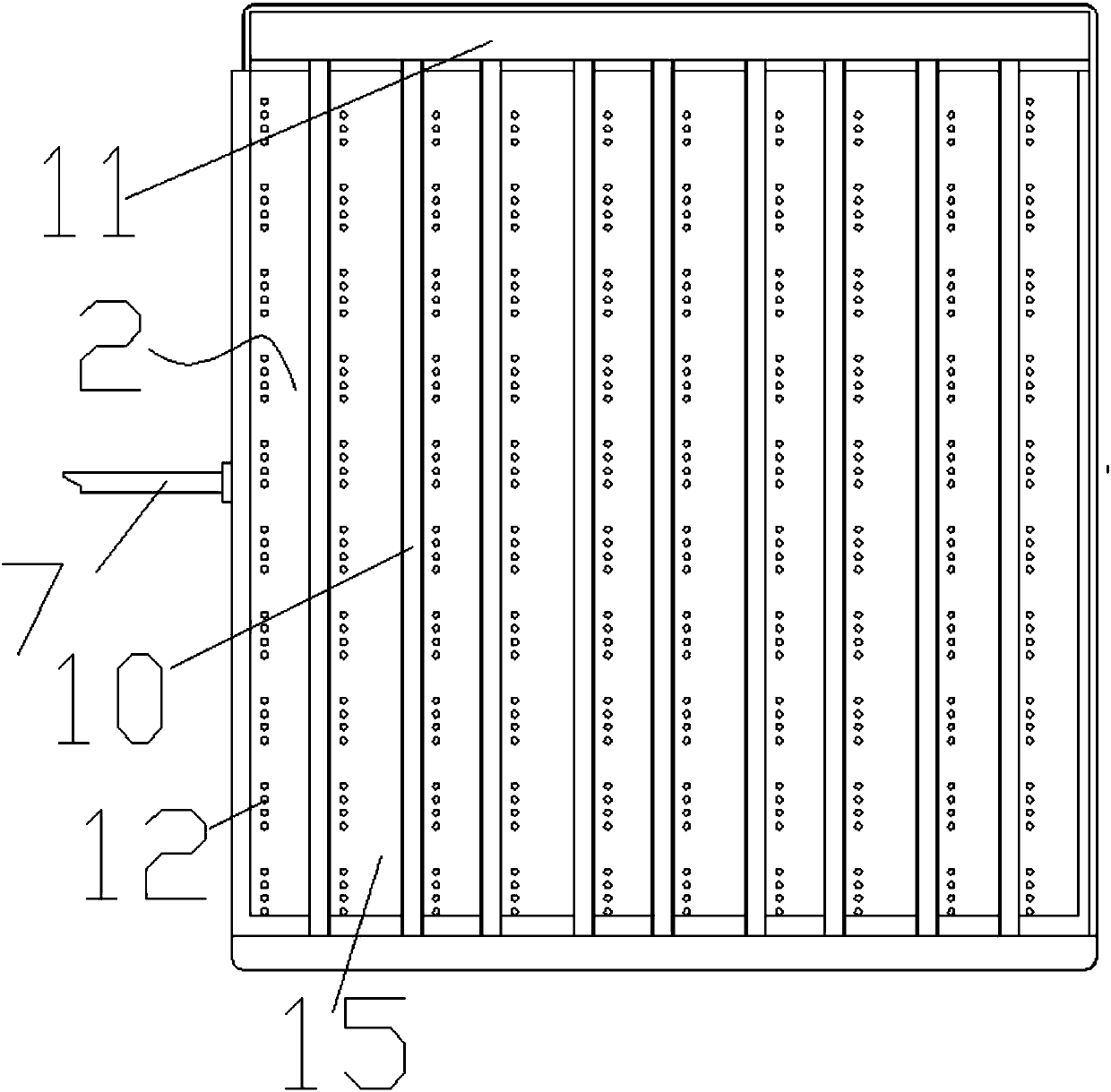

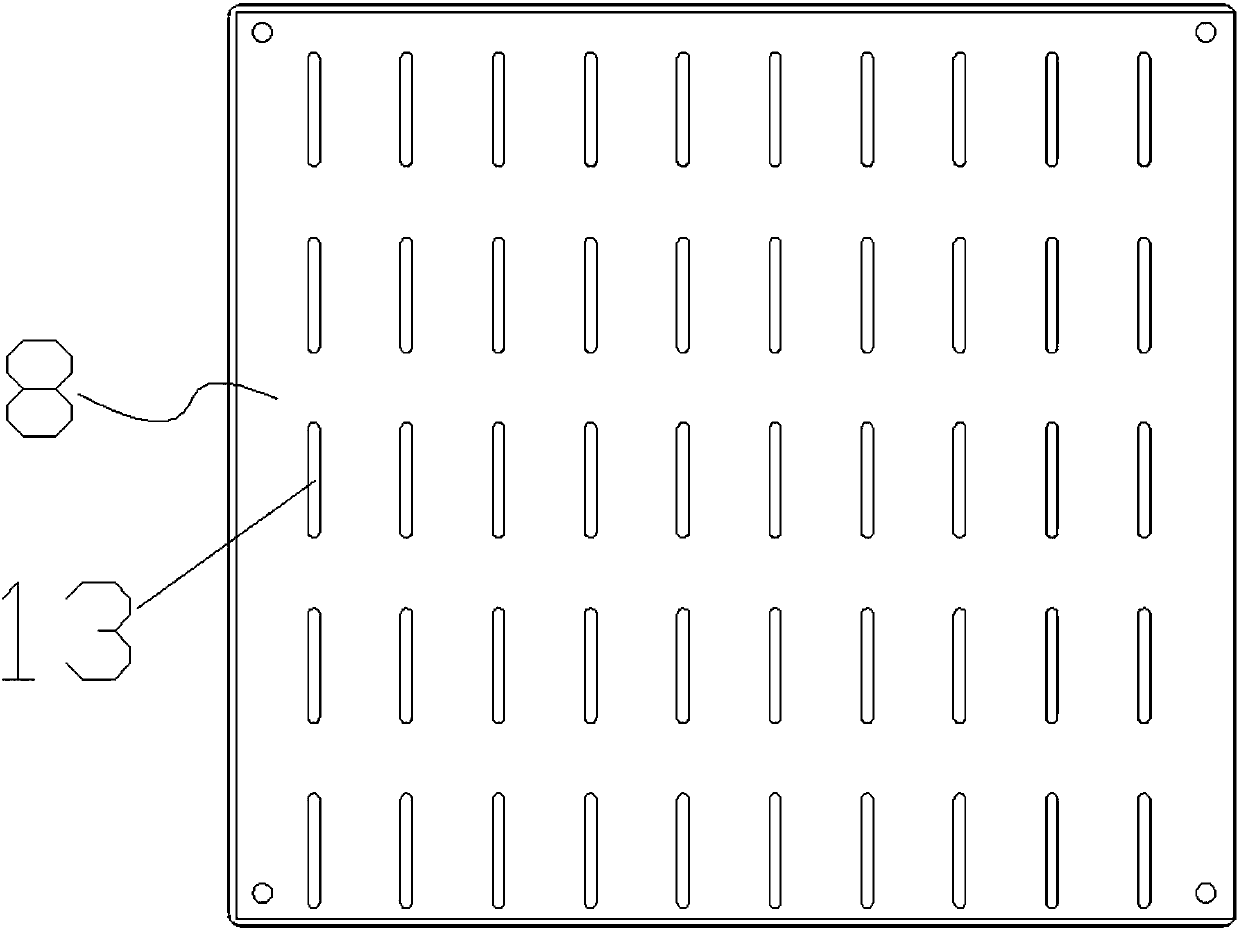

[0022] Such as Figure 1-5 Shown is the structural representation of the bean precision sowing device of the present invention; The present invention a kind of bean precision sowing device of the present invention, comprises frame 1, the seed measuring device 2 that is arranged on frame 1 and push-pull mechanism 3, so The frame is provided with a mounting plate 4 for fixing the seed measuring device 2, and the seed measuring device 2 includes a chassis 8, side weirs 1 arranged on the front and rear sides of the chassis 8, and a seed measuring plate 9 slidingly arranged on the chassis 8 1. The side weir II arranged on the left and right sides of the seed measuring plate 9 and no less than 2 seed retaining plates 10 erected between a pair of side weirs I, the side weir II on one side of the seed measuring plate 9 and the push-pull mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com