Amplitude-adjustable vibration screen

A vibrating screen and amplitude technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of complex excitation structure and inconvenient adjustment of the excitation force of the heavy hammer, and achieve a wide range of applications and a simple and easy adjustment method. , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

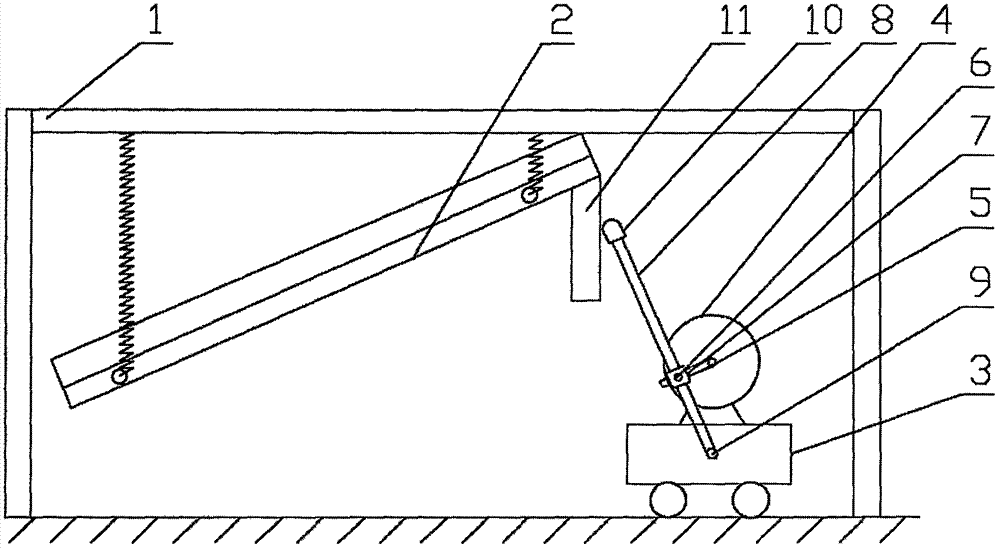

[0022] Such as figure 1 As shown, the amplitude-adjustable vibrating screen of this embodiment includes a vibrator, a suspension device 1, and a sieve plate 2 installed on the suspension device, and the vibrator includes a movable mounting bracket 3, The drive motor 4 is installed on the movable mounting bracket, the drive motor is connected to the needle bar 5 with adjustable length through the reducer, the needle bar is connected to the sleeve 7 through the first pin shaft 6, and the swing rod 8. One end passing through the sleeve is fixed by the second pin 9 arranged at the lower part of the movable mounting bracket, and the other free end is connected to the striking hammer 10 .

[0023] This embodiment adopts such a technical solution, and the working process is: when the drive motor drives the needle bar to rotate through the reducer, the needle bar drives the swing bar through the sleeve to make a swinging motion, and the hammer on the swing bar is moving along with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com