Forklift type small automatic guided vehicle

A forklift-type and trolley technology, which is applied in the field of warehouse management, can solve the problems that the goods cannot be too heavy, large in size, and low in effect, and achieve the effect of increasing the walking speed, reducing the transportation weight and reducing the rotation radius.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

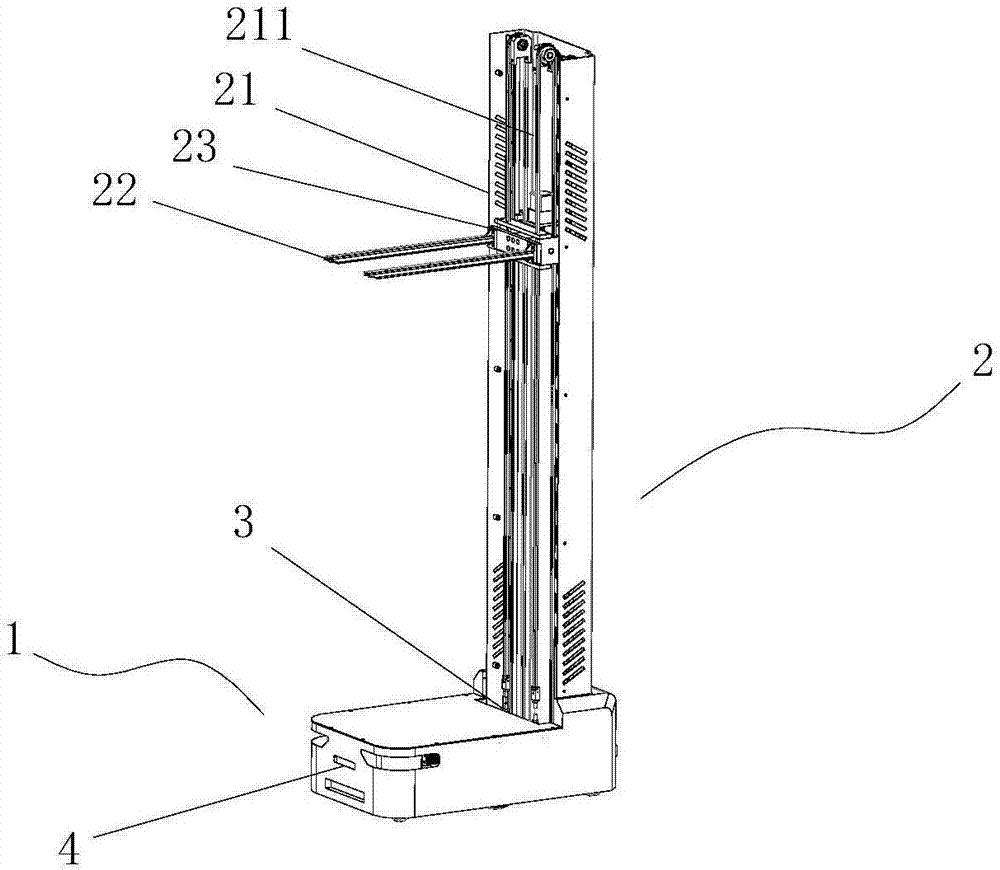

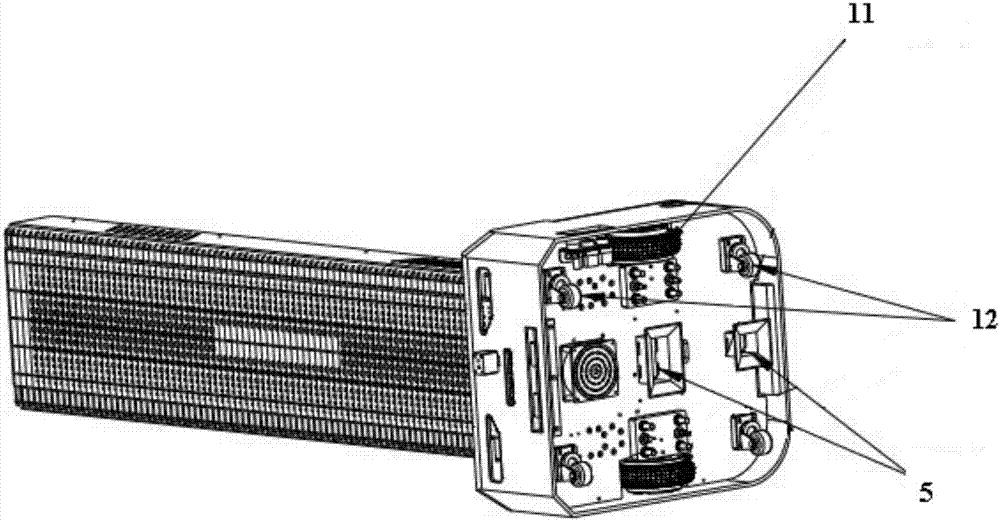

[0033] Such as Figure 1 ~ Figure 2 As shown, the forklift type AGV trolley according to the present invention combines the existing forklift with the AGV trolley, and in order to prevent the forklift rack of the forklift from occupying too much storage area, the forklift rack 2 is arranged on the AGV trolley body 1 On the surface, at the same time, in order to simplify the structure of the forklift frame 2, the function of steering when picking up goods is completed by the AGV trolley body 1, so that only the forklift frame 2 is required to move up and down. Simultaneously, the controller (not shown in the figure) completes the purpose of automatically picking up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com