Leak detection fixture and leak detection device

A leak detection and fixture technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid and using the liquid/vacuum degree for liquid tightness measurement, etc. The effect of digital change of negative pressure value, improved detection speed and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

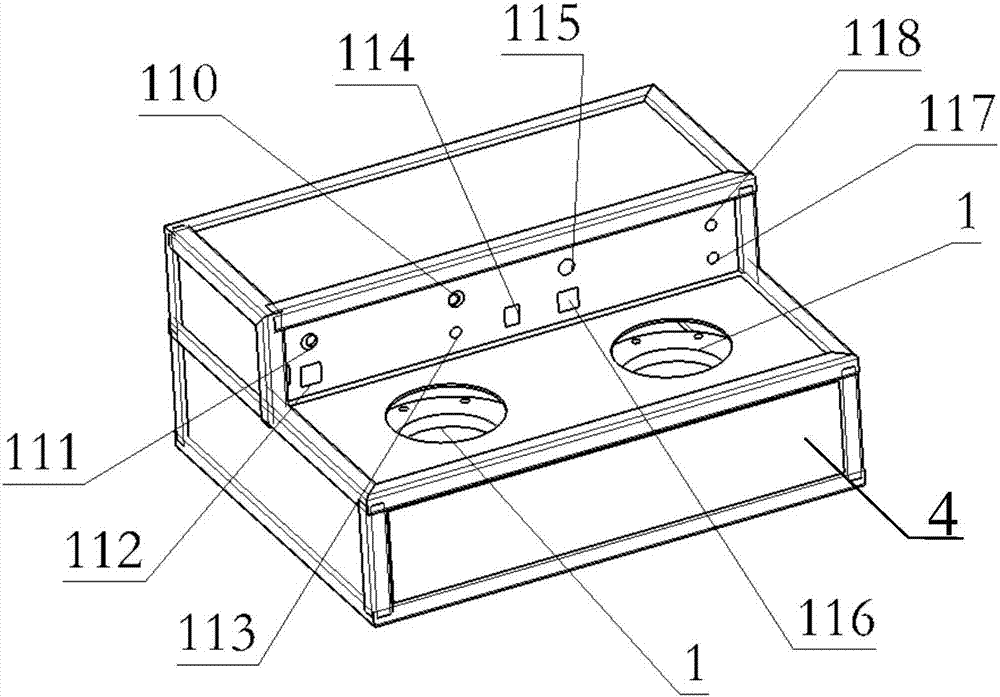

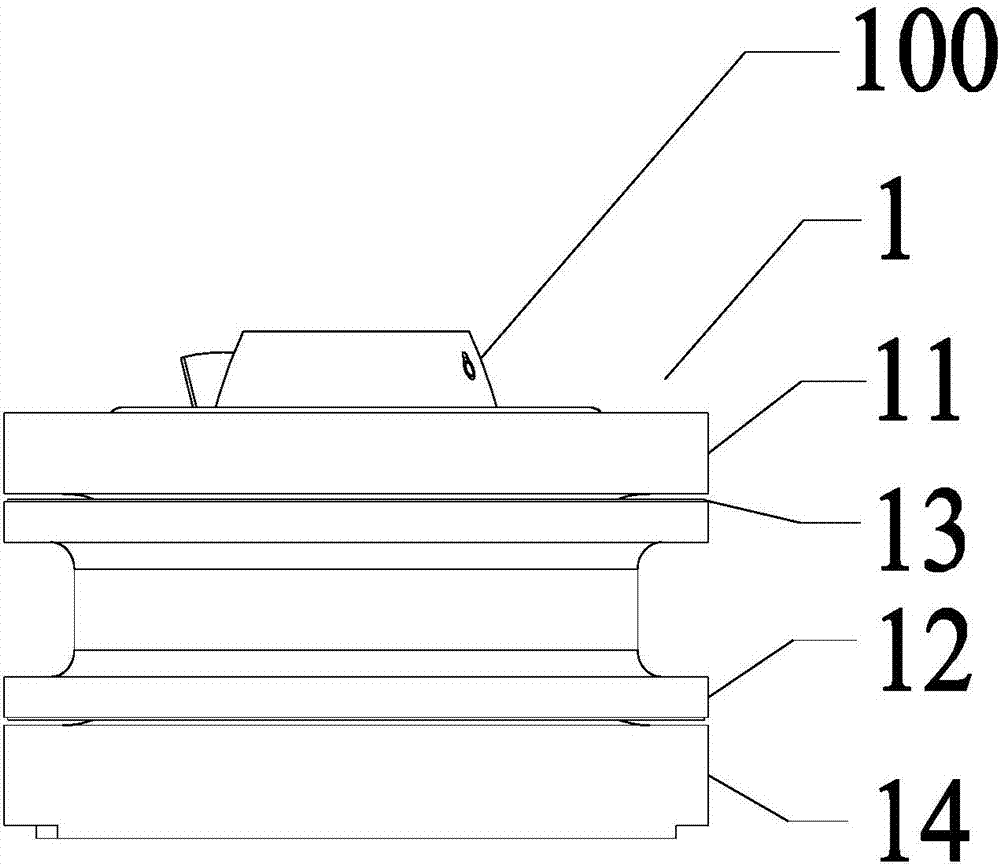

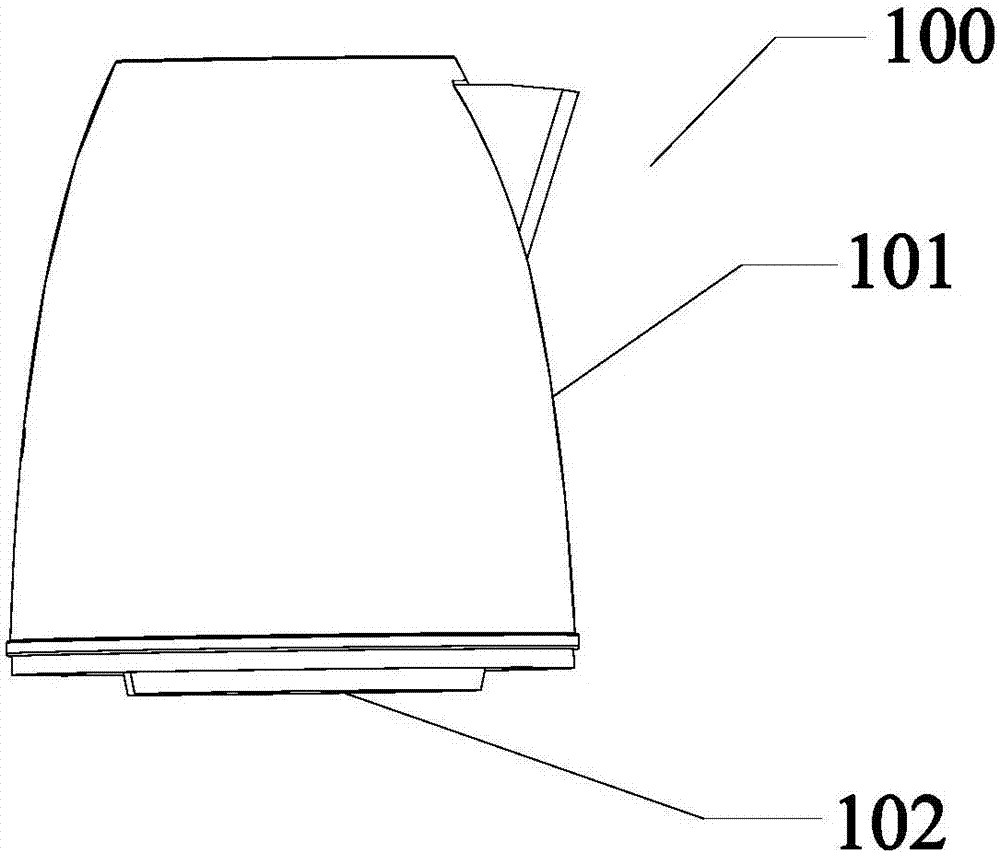

[0040] Such as figure 1 As shown, the present invention provides a first embodiment of a leak detection device, the leak detection device includes two leak detection fixtures 1, a housing 4, two detection and control devices, and each group of leak detection stations includes a Leak detection fixture 1, a detection and control device, each of the leakage detection fixture 1 corresponds to a detection and control device, the two leak detection fixtures 1 are arranged inside the shell 4, the two leakage detection fixtures 1 The detection and control device is arranged on the shell 4; the two detection and control devices include a start button 110 for station 1, a negative pressure sensor 112 for station 1, a negative pressure sensor 116 for station 2, a start button 118 for station 2, The controller (not shown in the figure), the start button 110 of the station 1 and the start button 118 of the station 2 are all connected with the air source and the air pump (not shown in the f...

no. 2 example

[0052] Such as Figure 7-8 As shown, the present invention provides a second embodiment of a leak testing device, which includes two sets of leak testing stations and a frame 7 (substantially equivalent to the housing 4 in the first embodiment), The frame 7 includes an upper bracket 71 and a desktop board 72. Each group of leak detection stations includes the leak detection fixture 1, detection and control device (not shown, and the same as the first embodiment) in addition to the leak detection fixture 1 as described in the first embodiment. In addition to the fact that the two detection and control devices described in the example are substantially equivalent), it also includes a press-down mechanism 2, and the leak detection fixture 1, the press-down mechanism 2, and the detection and control device are all arranged on the frame 7 , the pressing mechanism 2 is arranged on the upper bracket 71, the pressing mechanism 2 is located above the leak detection fixture 1; the detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com