Intermittent induction voltage-withstanding test device and test method for inter-turn insulation test of iron-core electric reactor

A voltage withstand test device, iron core reactor technology, applied in the direction of testing the dielectric strength, etc., can solve the problems affecting the effectiveness of the inter-turn insulation test, the uneven distribution of the initial impulse voltage, and the small change in the impedance of the reactor, etc., to achieve good Effect of control strategy, uniform distribution, fast data exchange

Pending Publication Date: 2017-08-15

HARBIN UNIV OF SCI & TECH

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional inter-turn insulation test method of iron-core reactor is mainly the lightning impulse method. The distribution of the initial impact voltage of this method is uneven, which affects the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

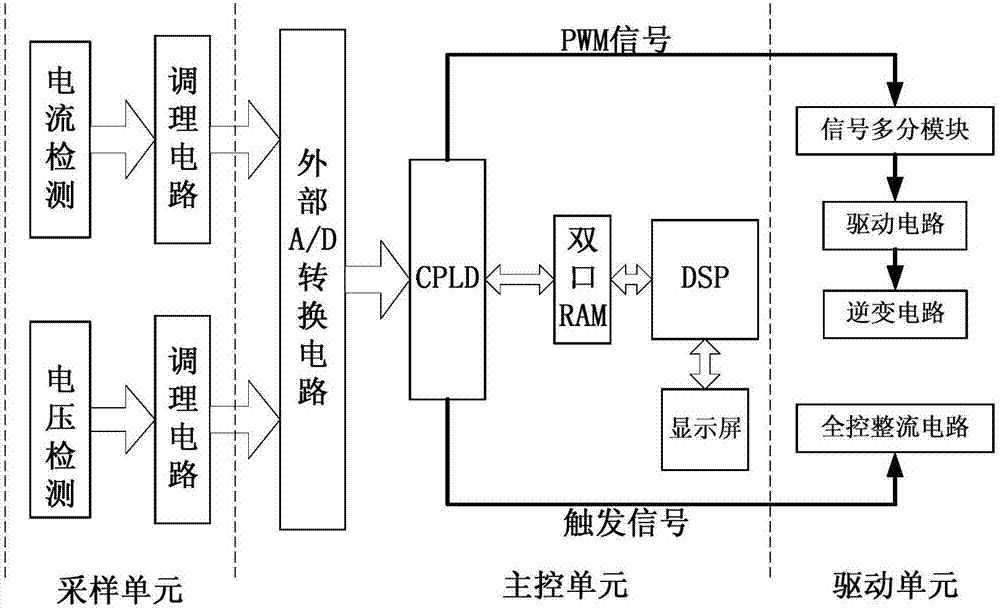

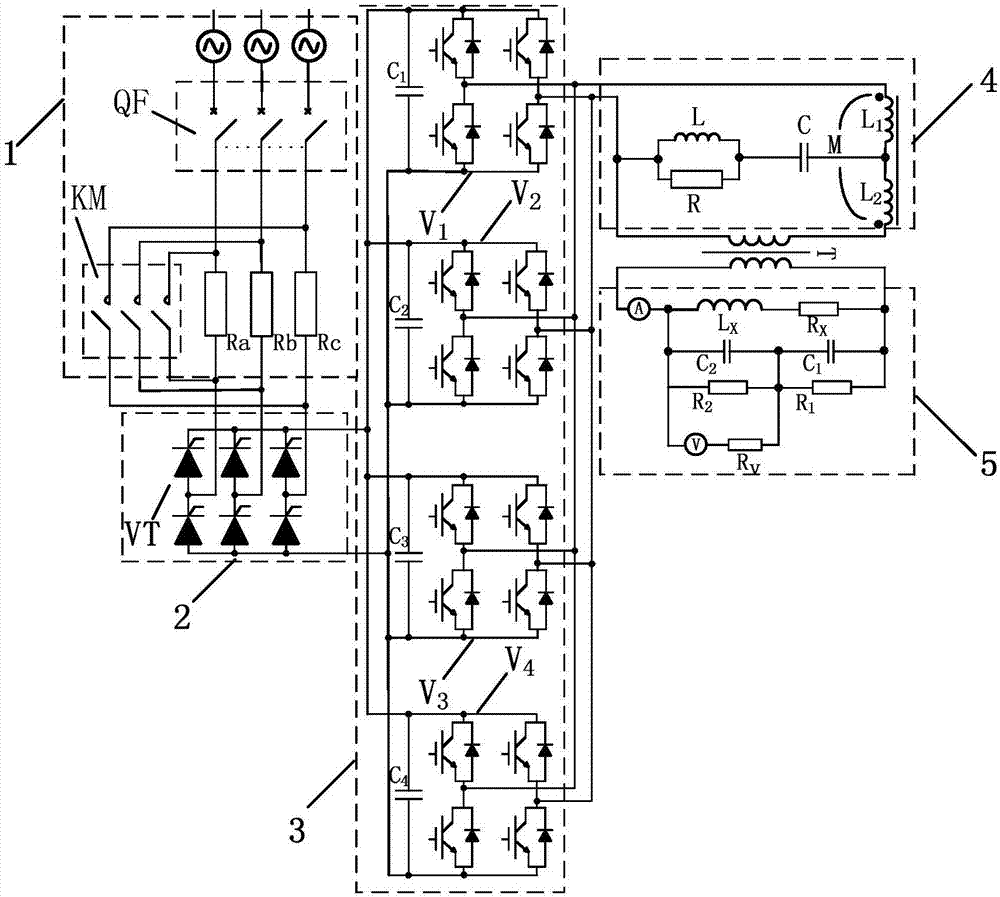

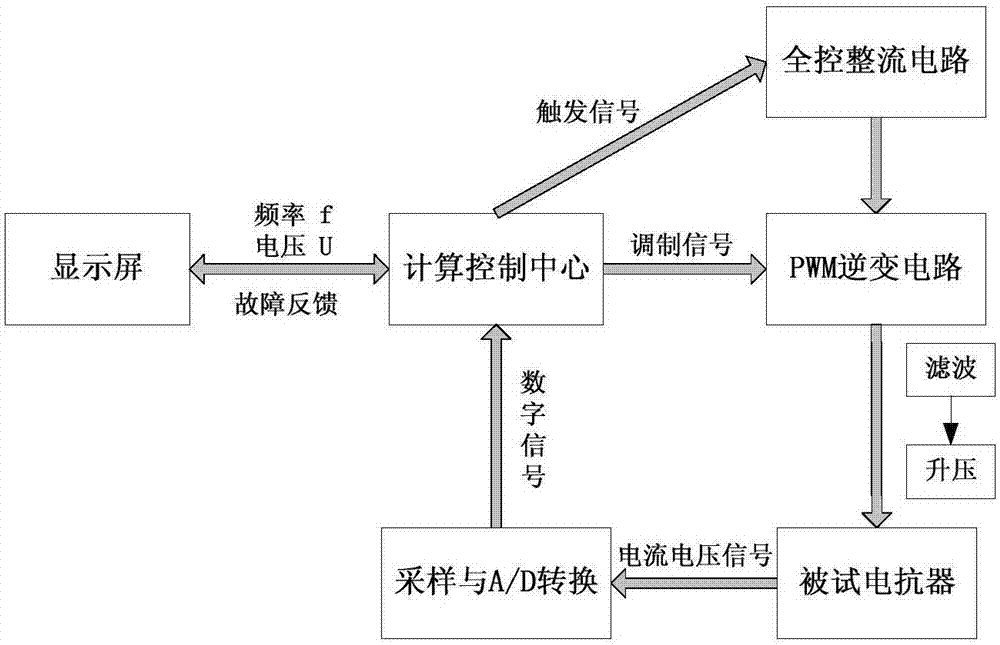

The invention relates to an intermittent induction voltage-withstanding test device and test method for inter-turn insulation test of an iron-core electric reactor. The test device comprises a controller, an inverter circuit, a chopper circuit and a detection circuit. The controller is connected with a display circuit and is connected with the inverter circuit and the chopper circuit by a drive module; and the detection circuit includes a voltage detection circuit and a current detection circuit, both of which are connected to the controller. In addition, the test method includes: the controller applies a voltage signal of a test voltage to two ends of a tested electric reactor; the controller carries out sampling on a practical voltage and a practical current of a test piece by the detection circuit and a phase difference between a sampling voltage and a sampling current is calculated; voltage boosting is carried out on the tested piece and a phase different after voltage boosting is measured and is used as a standard phase difference; and the phase difference and the standard phase difference are compared to determine the performance of insulation of the tested electric reactor. Therefore, a phase angle relation of the voltage and current can be analyzed and the quality of the tested piece can be evaluated in real time.

Description

[0001] Technical field: [0002] The invention relates to the technical field of inter-turn insulation testing of iron-core reactors, in particular to an intermittent induction withstand voltage test device and test method for inter-turn insulation testing of iron-core reactors. [0003] Background technique: [0004] With the development of the power system, the application of the single coil is more and more extensive, and the single coil is mainly a reactor. Whether it is an iron core reactor or a dry-type air-core reactor, in all operating accidents, the insulation damage accidents between turns of its coils account for the majority. In order to ensure the reliability of the inter-turn insulation, in addition to the operation department taking certain protective measures to limit the overvoltage below a certain amplitude, it is more important that the reactor manufacturing department should improve the manufacturing quality of the inter-turn insulation and take reasonable m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01R31/12

CPCG01R31/12

Inventor 朱东柏王震汤晓先王法恒

Owner HARBIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com