Disc feeding machine

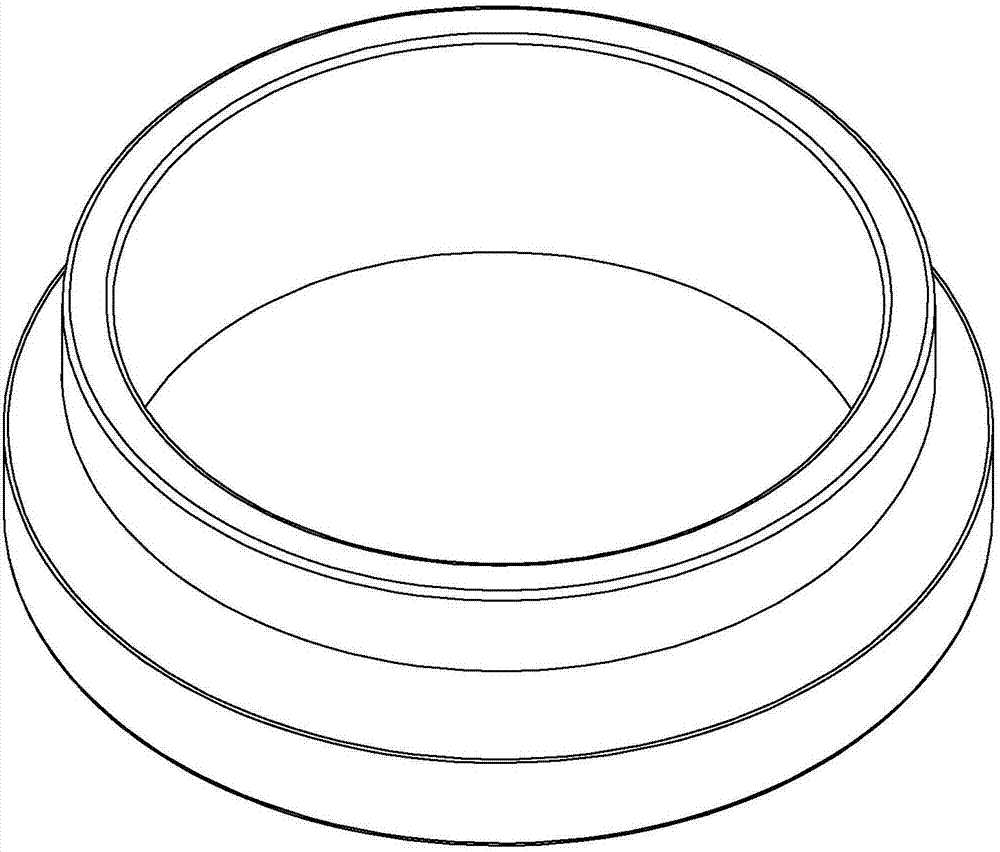

A technology of feeding machine and disc, applied in the field of automatic feeding device, can solve the problems of bearing ring damage, bearing ring being automatically turned over, etc., to achieve the effect of not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

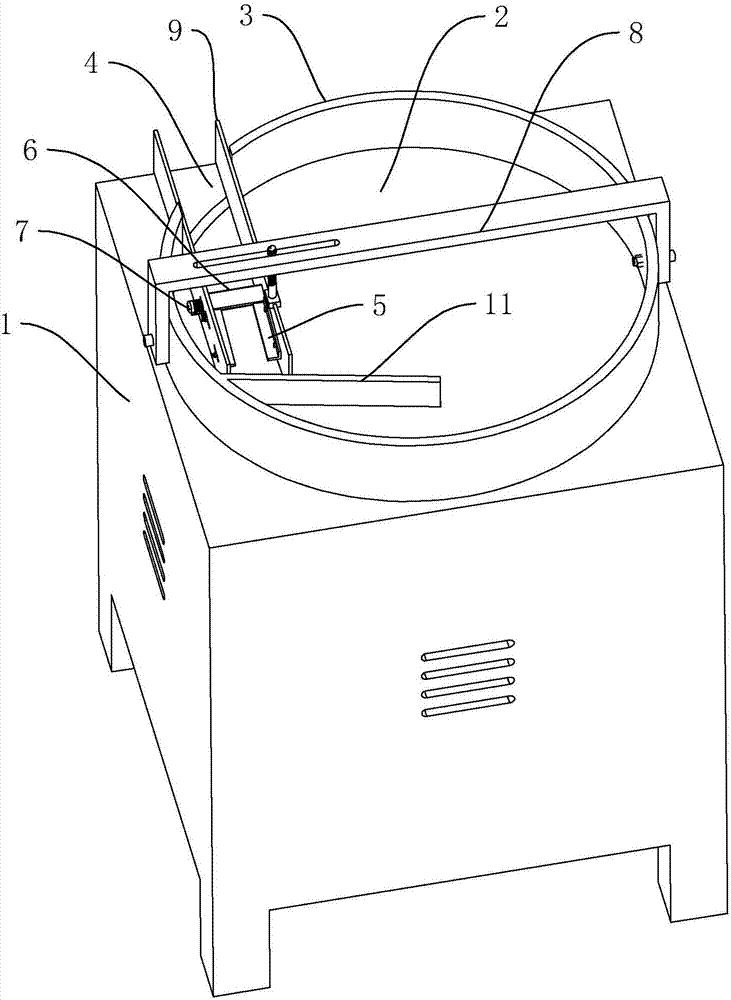

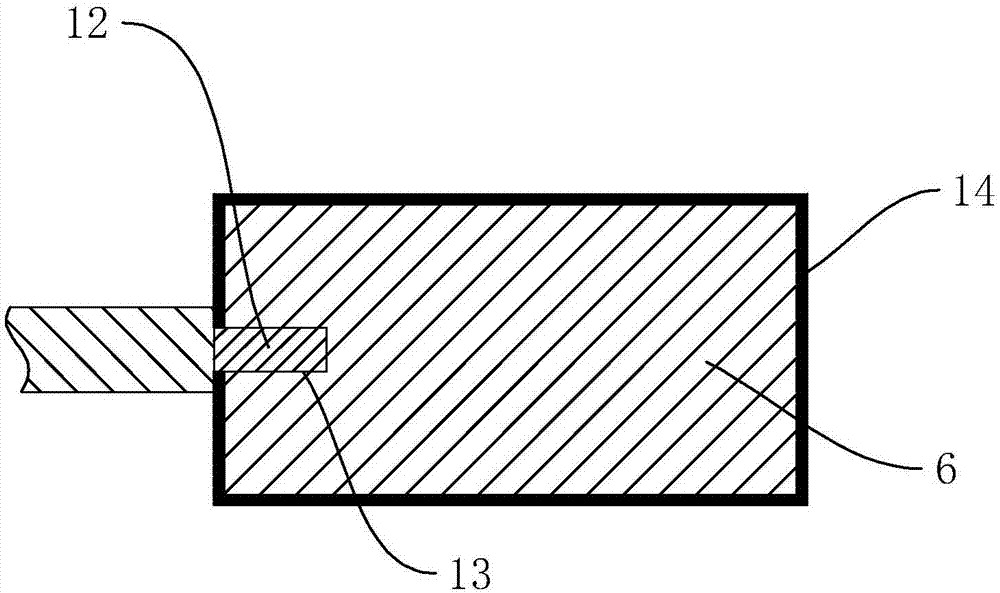

[0029] Such as figure 1 As shown, a disc loading machine includes a frame 1, on which a disc body 2 is horizontally rotatably arranged, and on the frame 1 is provided with an outer frame 3 arranged around the disc body 2, the outer frame 3 There is a feeding channel 4 that communicates with its inner and outer space. The feeding channel 4 is composed of two guide plates 9. A frame body 8 is provided on the frame 1. The two guide plates 9 are provided with a frame body away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com