Mine lifting equipment with high safety performance

A technology of safety performance and lifting equipment, applied in the direction of hoisting equipment safety devices, lifting devices, etc., can solve problems such as increased maintenance costs, uneven inclination, and easy damage to components, so as to improve safety and practicability and prolong service life , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

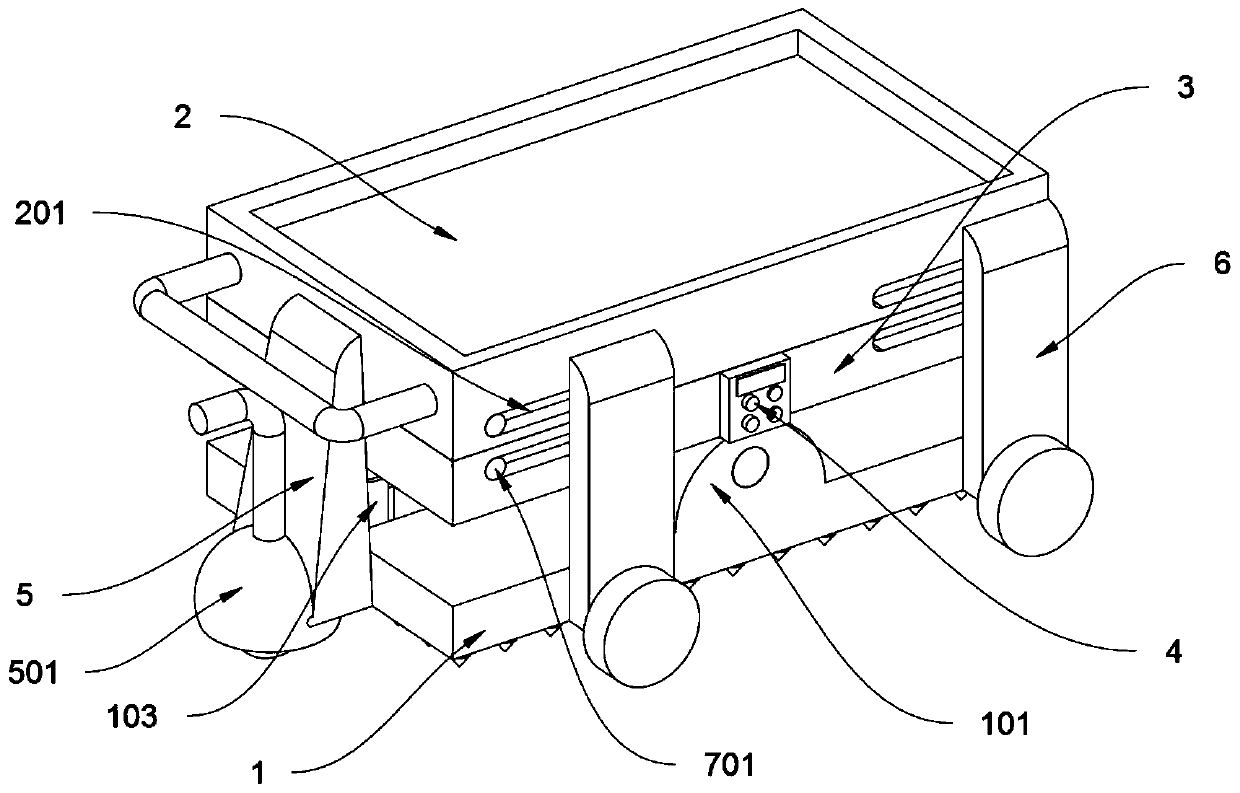

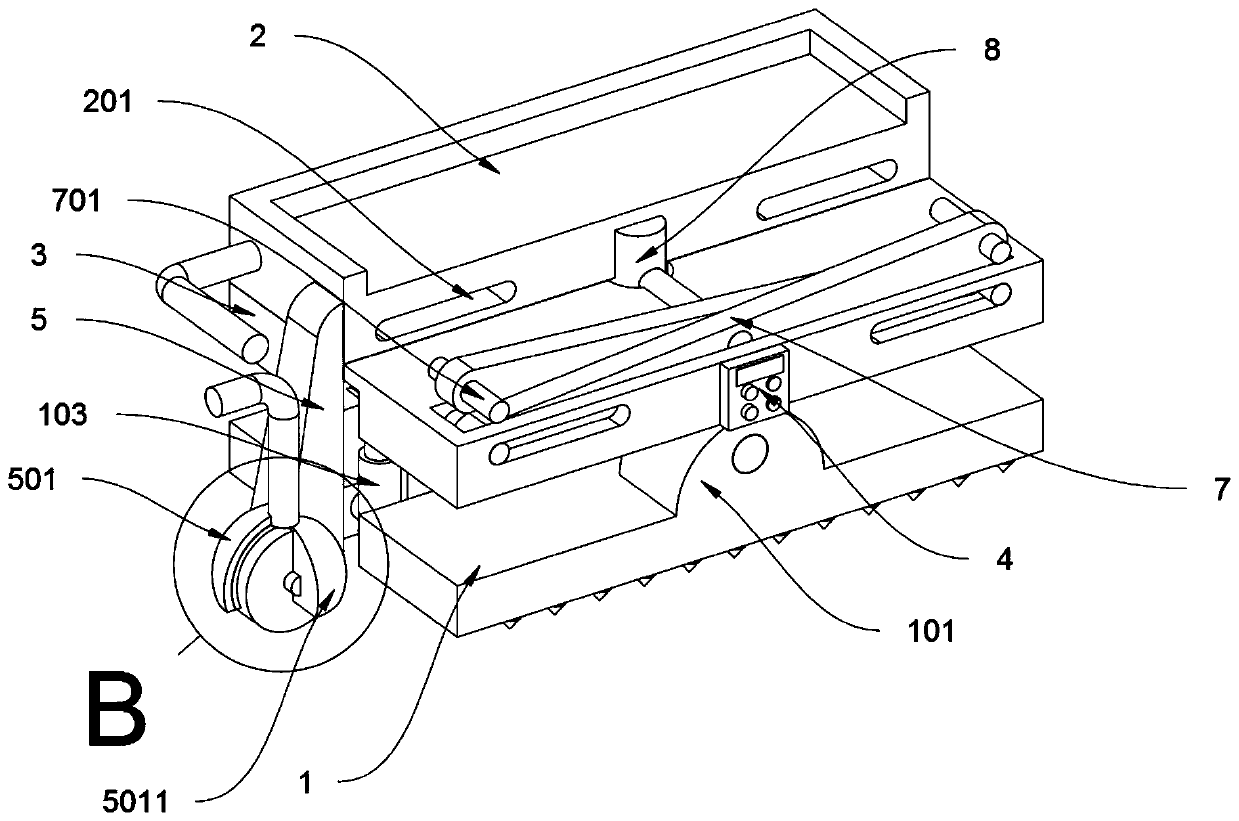

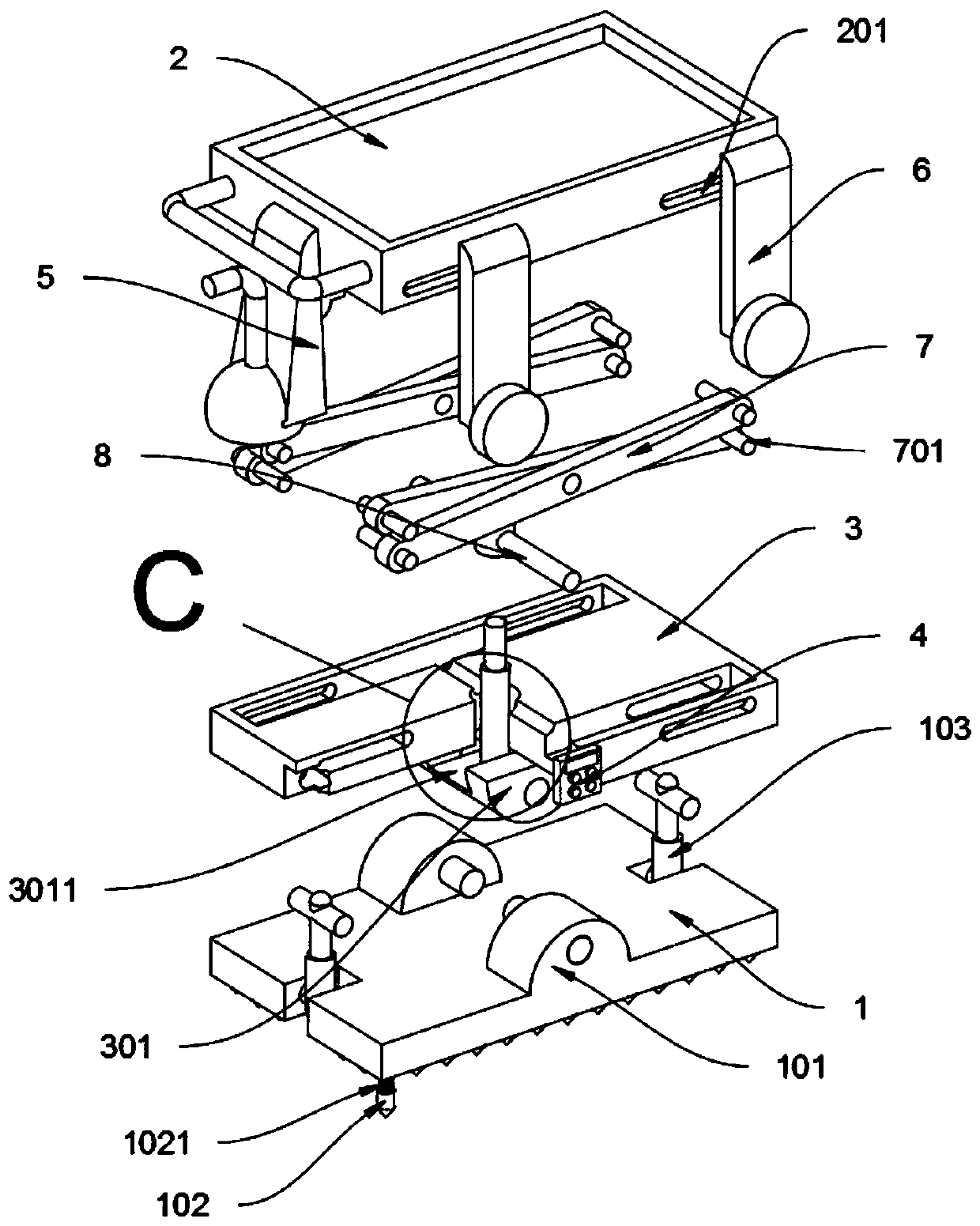

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a mine lifting device with high safety performance, which includes a base 1, a loading platform 2, a control switch 4, a guide wheel 5, a moving wheel 6, a lifting frame 7 and a transmission rod 8; the top of the base 1 is flexibly connected and adjusted The bottom of the platform 3; the two sides of the middle part of the top surface of the base 1 are provided with an upright semicircular ring 101, and the middle part of the bottom surface of the adjustment platform 3 is provided with an inverted semicircular mounting ring 301, and the mounting ring 301 passes through the pin rod and the semicircular ring 101 Activity Link, as attached figure 2 , attached image 3 And attached Figure 4 As shown; the loading platform 2 is movably connected to the top of the adjustment platform 3; when the loading platform 2 is in the lowest position, the height of the bottom of the wheel body of the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com