U-type steel bracket capable of actively stabilizing surrounding rock

A technology of profiled steel and surrounding rock, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve problems such as insufficient support performance, reduced self-supporting capacity of surrounding rock, unstable supporting structure, etc. The effect of surrounding rock stability control, surrounding rock stability, and improving support performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

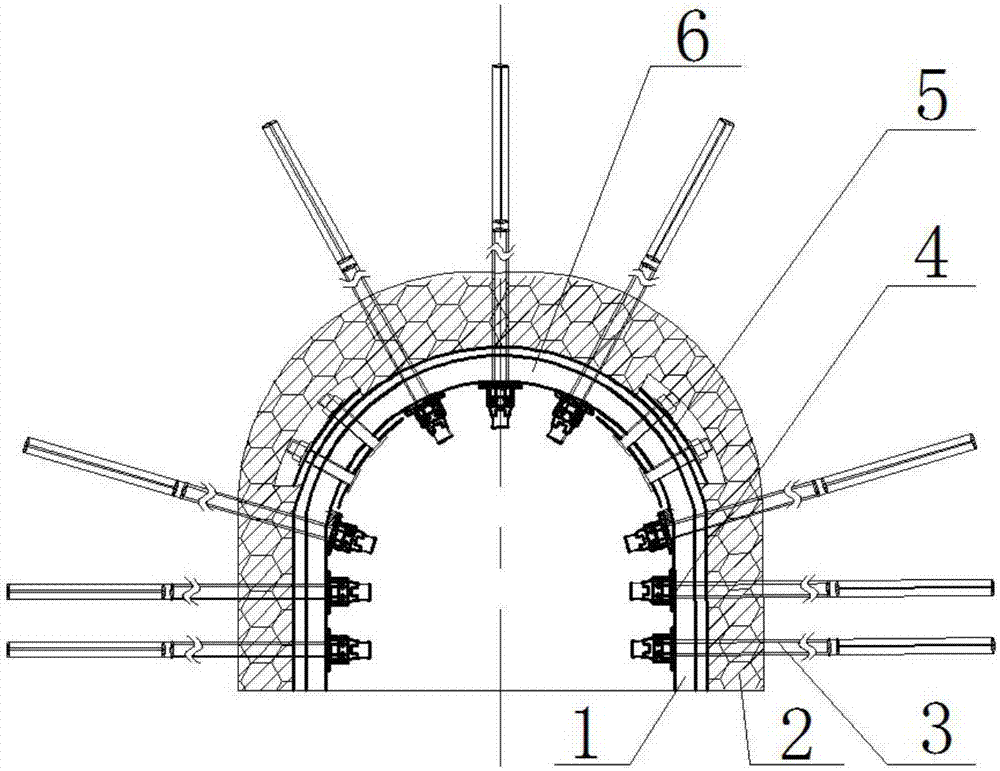

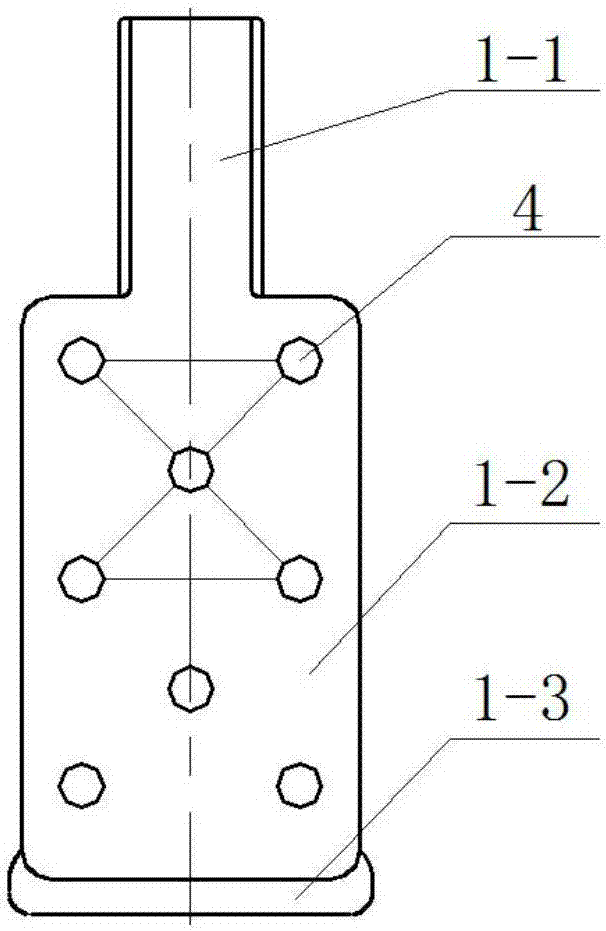

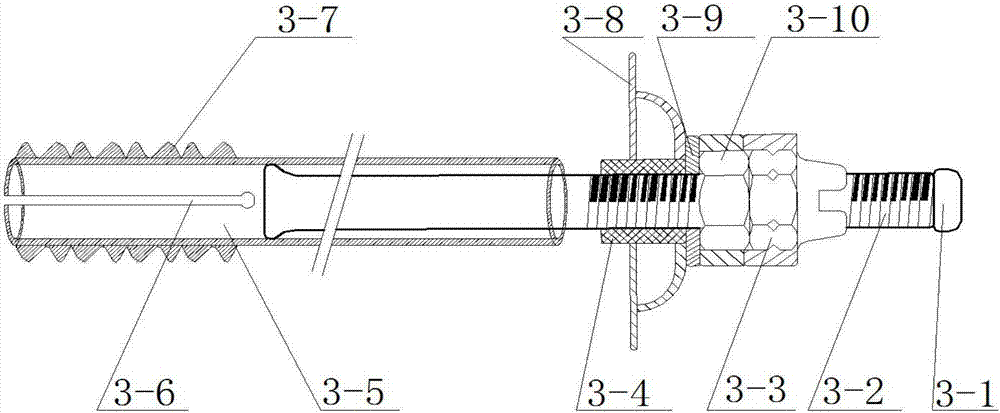

[0028]Working principle: The two ends of U-shaped steel 6 on the vault are inserted or overlapped on the bending section 1-1 of the special-shaped U-shaped steel 1 on the legs of the two sheds, and the overlapping parts of the two are fixed with clamps 5 to form a U-shaped steel bracket The basic structure; the U-shaped elastic filling element 2 is in close contact with the groove side of the arch U-shaped steel 6, and the widened edge of the special-shaped U-shaped steel 1 of the shed legs and the groove side. During the support process, it can Ensure that the filling between the bracket and the surrounding rock is dense, effectively simplify the post-filling process of the U-shaped steel wall, and the joints between adjacent U-shaped elastic filling elements 2 are processed with concave-convex meshing structures 2-1, 2-2, and the two are meshed and embedded The connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com