Profiled bar skeleton T-shaped groove type angle connection fastening corner frame structure

A technology for connecting and tightening, special-shaped materials, applied in the direction of connecting components, furniture connection, mechanical equipment, etc., can solve the problems of inconvenience, time-consuming, high installation cost, and achieve the effects of convenient processing, simple operation, and firm assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

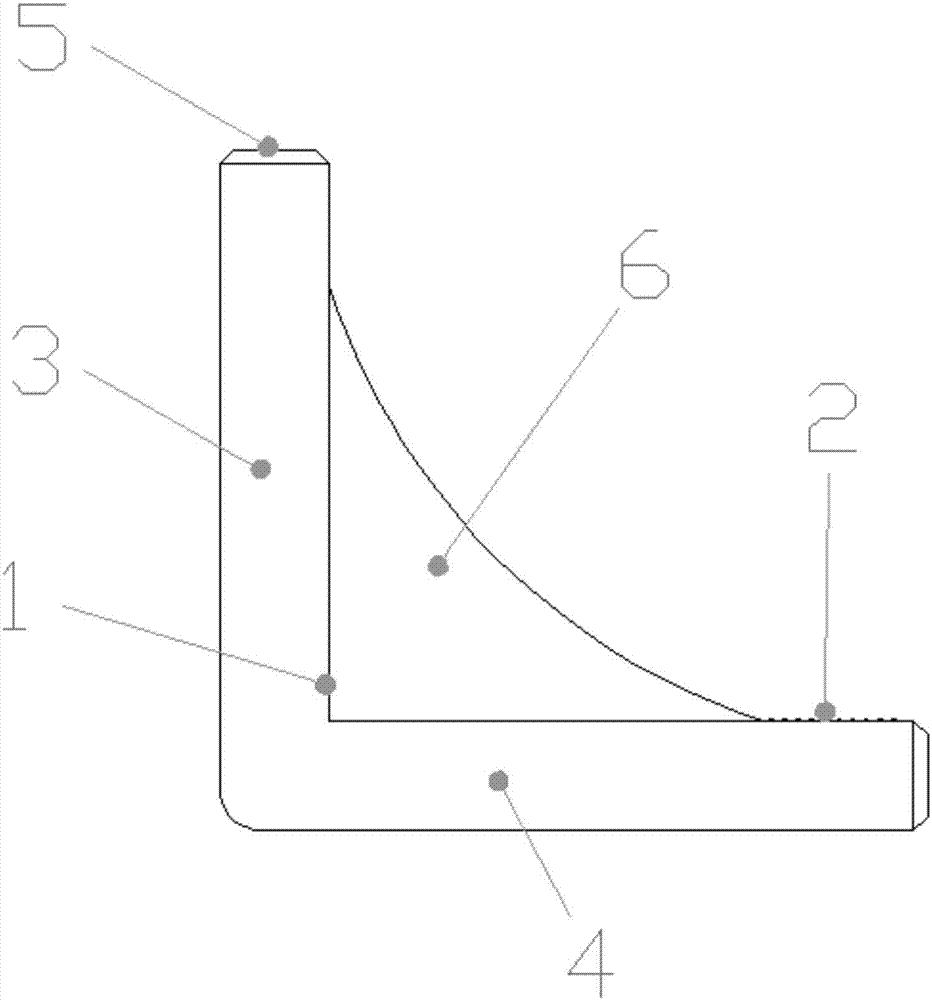

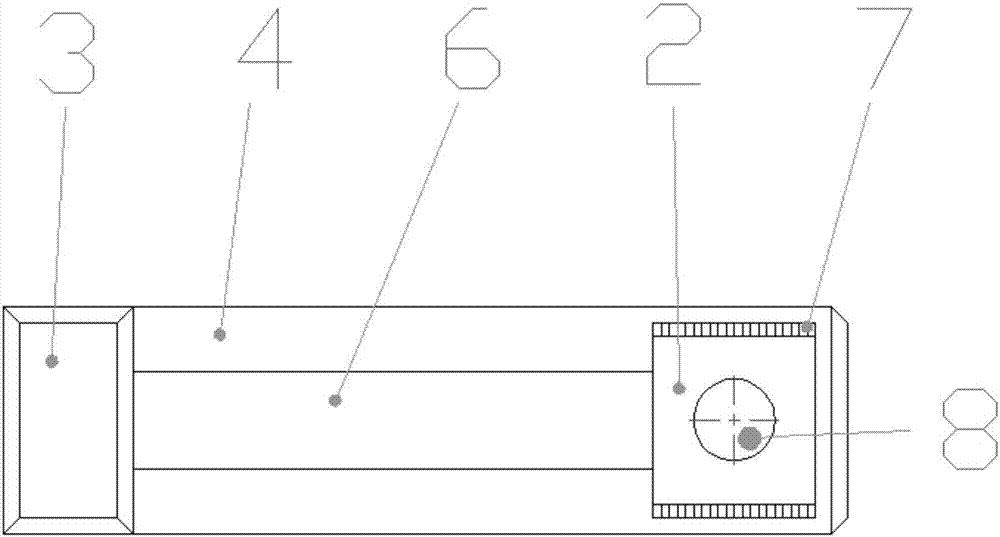

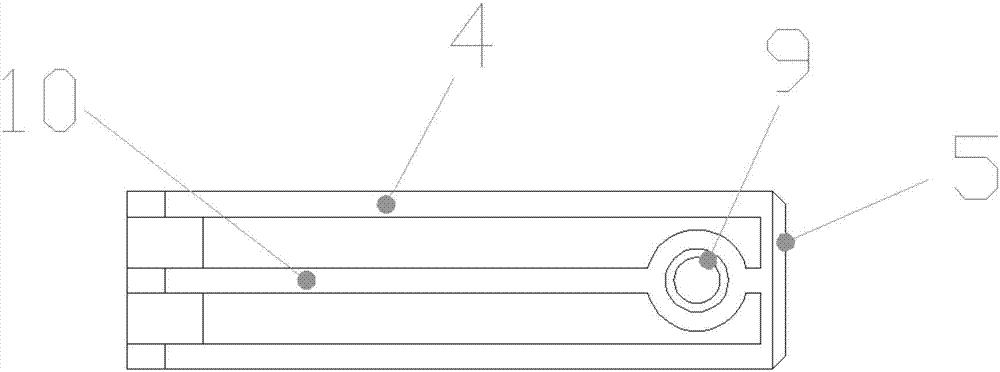

[0027] refer to Figure 1 to Figure 11 As shown, the profile frame T-shaped slot-type angle connection fastening corner frame structure includes a T-shaped head two-end plug-in structure 1 and a ratchet stamping sheet 2, and the T-shaped head two-end plug-in structure 1 includes a first plug body 3 With the second plug body 4, there is an angle between the two plug bodies, and a connection reinforcing rib 6 is provided between the first plug body 3 and the second plug body 4, which is strong and resistant to deformation. The ratchet stamping sheet 2 Located on the plug body connected to the edge of the reinforcing rib 6, the ratchet stamping sheet 2 is provided with ratchets 7 on both sides, and a fastening hole 8 is provided in the middle, which can be connected with common fasteners to form two special-shaped materials into a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com