Carriage locking pin zoom system

A lock pin and scaling technology, applied in the direction of mechanical equipment, connecting components, etc., can solve the problems of inconvenient disassembly of shelves, unsafe driving, insufficient extension force of locking pins, etc., to improve driving safety, large extension force, and easy disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

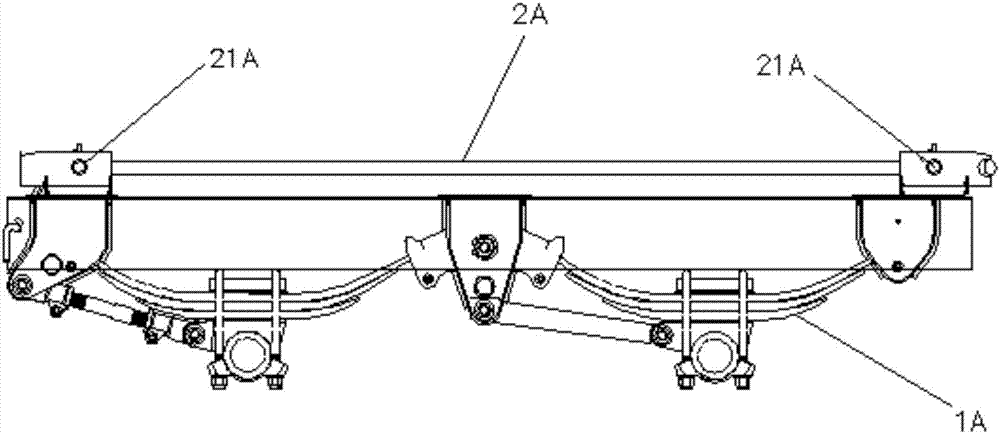

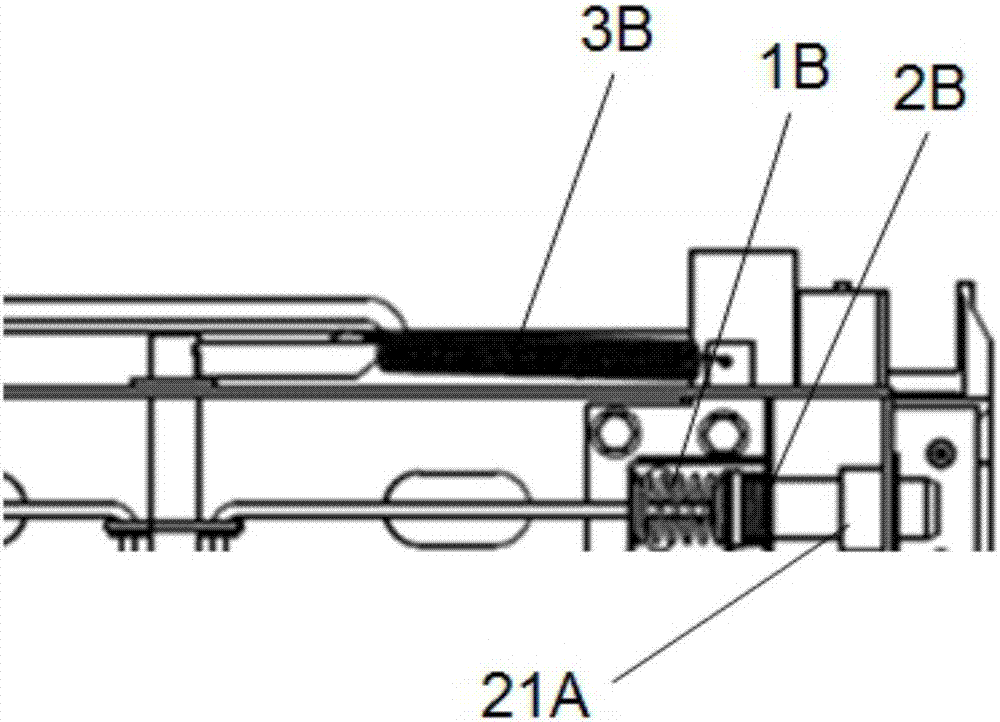

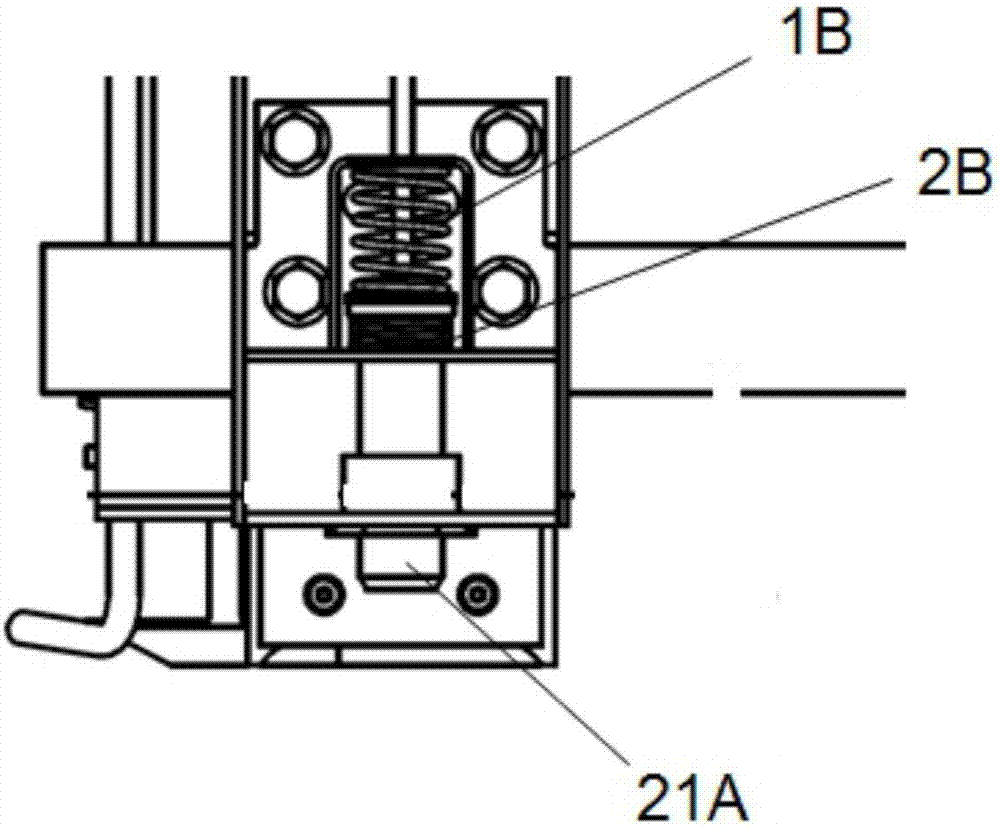

[0031] Such as Figure 4 , Figure 5 , Figure 6 and Figure 10 as shown, Figure 4 It is a top view of the zoom system of the carriage lock pin of the present invention; Figure 5 It is a partial cross-sectional view of the zoom system of the carriage lock pin in the present invention; Figure 6 is a partially enlarged view of M; Figure 10 is a side view of the locking pin. A sliding frame lock pin scaling system, comprising a base frame 1, two sets of lock pin mechanisms, and a drive rod 3; the two sets of lock pin mechanisms are respectively arranged at the front and rear ends of the base frame 1; each set of lock pin mechanisms includes two Two lock pin mechanisms, described two lock pin mechanisms are arranged on the symmetrical both sides of underframe; Described each lock pin mechanism comprises lock pin 8, outer spring 9, inner spring 10, extension spring frame 5, pull ring 6 , the pin spring sleeve 11 and the connecting rod 7; the locking pin 8 includes a prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com