Device measuring cylindricity of outer surface of axis part automatically

A technology for automatic measurement of shaft parts, applied in the field of parts detection devices, can solve the problems of low detection efficiency and precision, achieve accurate detection and avoid measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

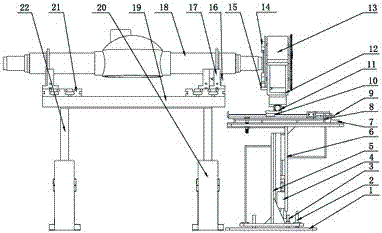

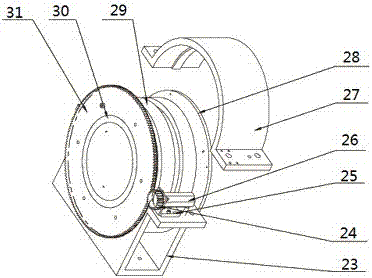

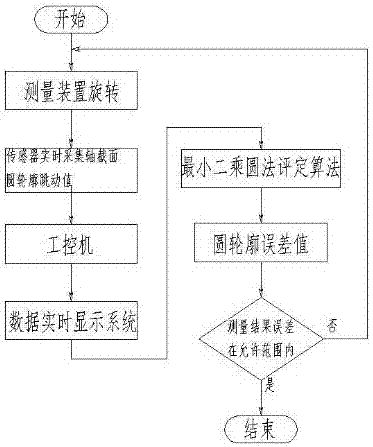

[0021] Embodiment 1: A device for automatically measuring the cylindricity of the outer surface of shaft parts, including a placement platform and a detection platform. The placement platform includes a support frame 22 and a worktable 19. Connected with the worktable 19, a workpiece placement block 17 is arranged on the working surface of the worktable 19; a detection platform is placed on one side of the worktable 19, and the detection platform includes a base 1, a vertically moving support seat 6 , fixed platform 12, detection platform 13, wherein said up and down movement support base 6 is installed on the base 1, fixed platform 12 is installed on the up and down movement support base 6, detection platform 13 is installed on the fixed platform 12, detection platform 13 at least Including driving gear 24, rotating motor 26, intermediate drum 30, rotating gear 31, the output shaft of said rotating motor 26 is connected with driving gear 24, driving gear 24 meshes with rotatin...

Embodiment 2

[0022] Embodiment 2: A device for automatically measuring the cylindricity of the outer surface of shaft parts, wherein the support frame 22 is connected to the adjusting hydraulic cylinder 20 . The vertical support seat 6 includes a vertical support seat 4 and a vertical movement lead screw 5 , and the up and down movement lead screw 5 is connected with the vertical support seat 6 through the vertical support seat 4 . The structure and connection relationship of the remaining parts are the same as those described in Embodiment 1.

Embodiment 3

[0023] Embodiment 3: A device for automatically measuring the cylindricity of the outer surface of shaft parts, wherein the fixed table 12 is provided with a front and rear adjustment screw 11, and the front and rear adjustment screw 11 is connected to the detection table 13 through a connecting piece. Also be provided with left and right adjustment leading screw 10 on described fixed platform 12, left and right adjustment leading screw 10 is connected with front and rear adjustment leading screw 11 by connector, and one end of left and right adjustment leading screw 10 is connected with left and right control motor 9. The workpiece placement block 17 is provided with a laser alignment transmitter 16 , and the detection table 13 is provided with a laser alignment receiver 15 paired with the laser alignment transmitter 16 . The left and right adjustment lead screws 10 are connected with the adjustment base 7, and the adjustment base 7 is provided with an adjustment screw 8. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com