A display panel and a display device

A technology for display panels and display substrates, applied in instruments, nonlinear optics, optics, etc., can solve problems such as residual stress of display panels, and achieve the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0031] The present invention provides a solution to the problem of residual stress after box alignment in the prior art due to the uneven thickness of the film layer of the substrate.

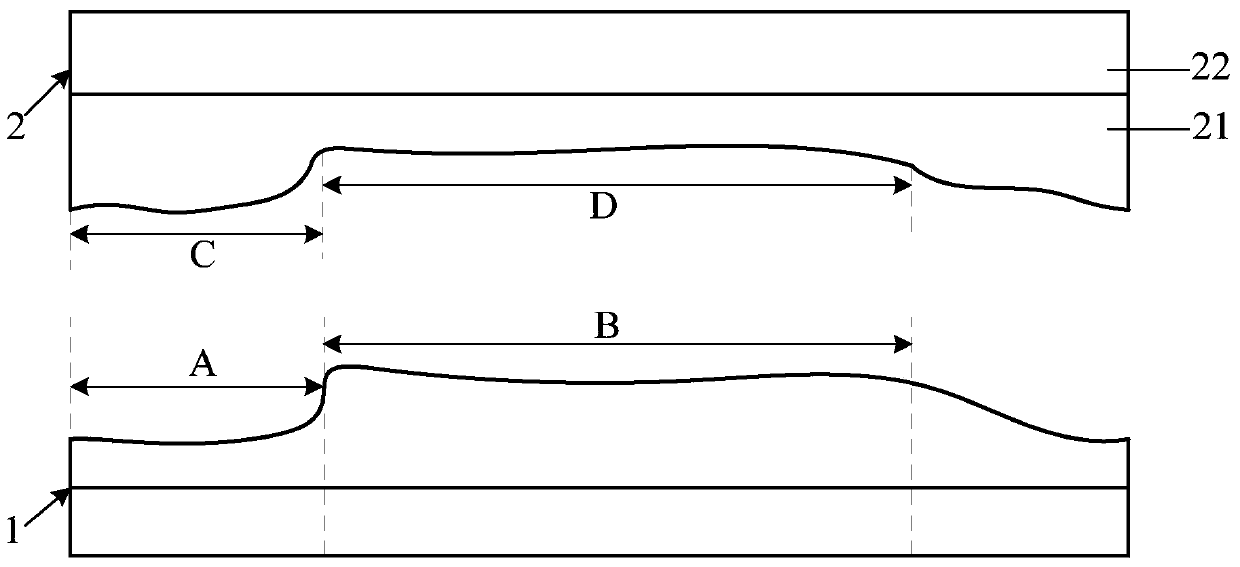

[0032] On the one hand, the embodiment of the present invention also provides a display panel, such as figure 1 As shown, it includes a display substrate 1 and a box-matching substrate 2 arranged in a box-to-box arrangement. Wherein, the display substrate 1 has at least a first part A and a second part B with different thicknesses formed on the side facing the box substrate 2 , the thickness of the first part A on the display substrate 1 is smaller than the thickness of the second part B on the display substrate 1 . That is to say, the display substrate 1 has the problem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com