Lightweight seat for vehicles

A seat, lightweight technology, applied in vehicle seats, special positions of vehicles, vehicle parts, etc., can solve problems such as seat weight, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

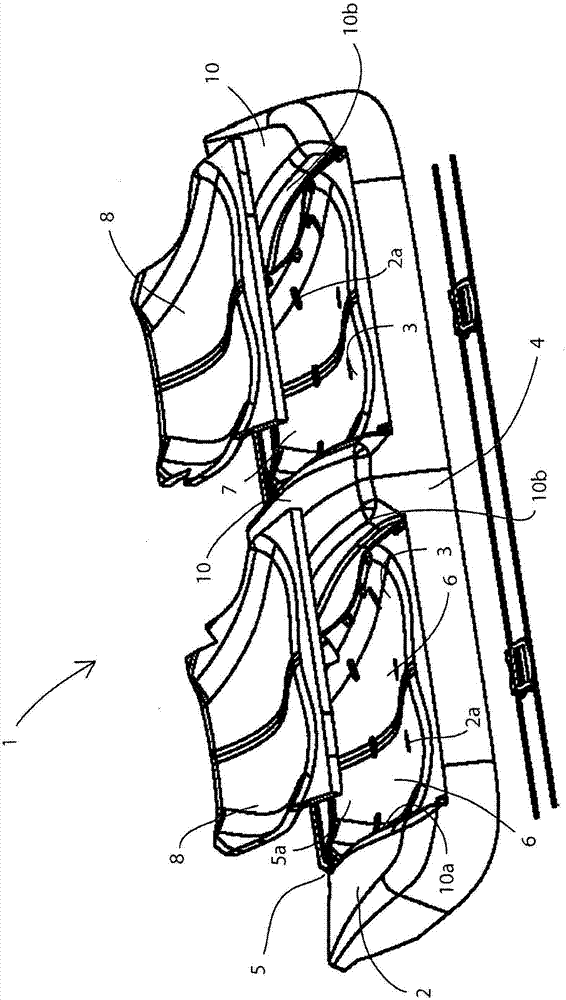

[0026] exist figure 1 An exemplary embodiment of a seat 1 for a vehicle and of a lightweight construction seat 1 is shown in . The seat shown represents a rear seat for a motor vehicle, which comprises a support part 2 , wherein the support part 2 is made of a dimensionally stable material. In the sense of the invention, a dimensionally stable material is a foam which is not compressible like soft foam, but bears the weight of the seat user without significant deformation thereof. The dimensionally stable material used here consists entirely of an expanded polypropylene particle foam (EPP). Furthermore, it can be seen that the support part 2 essentially forms the entire lightweight seat 1 (except for the two upholstery layers 8 ).

[0027] The support part 2 has two seat shells 3 for each seat user. The seat shell 3 can be subdivided substantially into three seat shell sections 5 a , 6 . In the installed state (not shown), a gasket layer 8 is applied to the housing section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com