A device for removing unqualified products for a production line

A qualified product and production line technology, applied in the direction of transportation and packaging, conveyor objects, sorting, etc., can solve the problems of unfavorable production efficiency of the company, automatic waste removal device is not automatic enough, etc., achieve simple mechanical principles, reduce capital costs, Eliminate the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

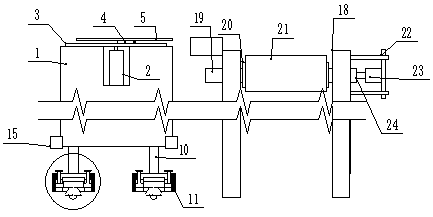

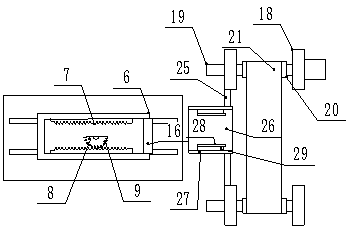

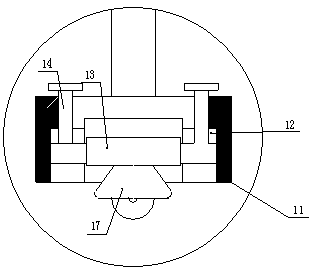

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a device for removing unqualified products for a production line includes a base 1, a feeding mechanism is installed on one side of the base 1, and a matching removal mechanism is installed on the feeding mechanism, and the outer upper surface of the base 1 is processed with a A rotating motor 2 is fixedly embedded in the through hole, and slide rails 3 are respectively installed on the outer upper surface of the base 1 and located on both sides of the through hole, and a slide block movable therein is installed in the slide rail 3 4. A rectangular block 5 is fixedly installed on the outer upper surface of the set of sliders 4, and a rectangular groove 6 is processed on the outer upper surface of the rectangular block 5, and a number rack is installed on the opposite side surface of the rectangular groove 6 7. A rotating motor 2 is installed on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com