Full-automatic motor rotor cleaning machine

A technology for motor rotors and cleaning machines, which is applied to cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as low efficiency, inconvenient rotation, and poor effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

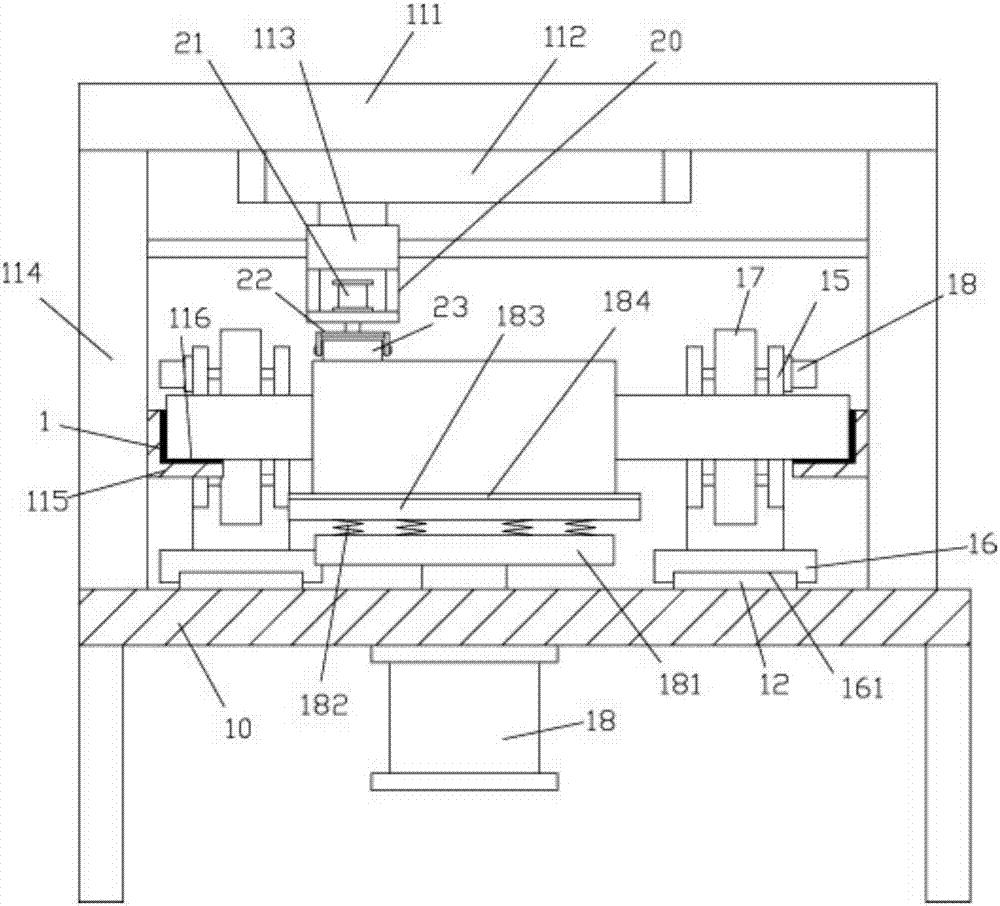

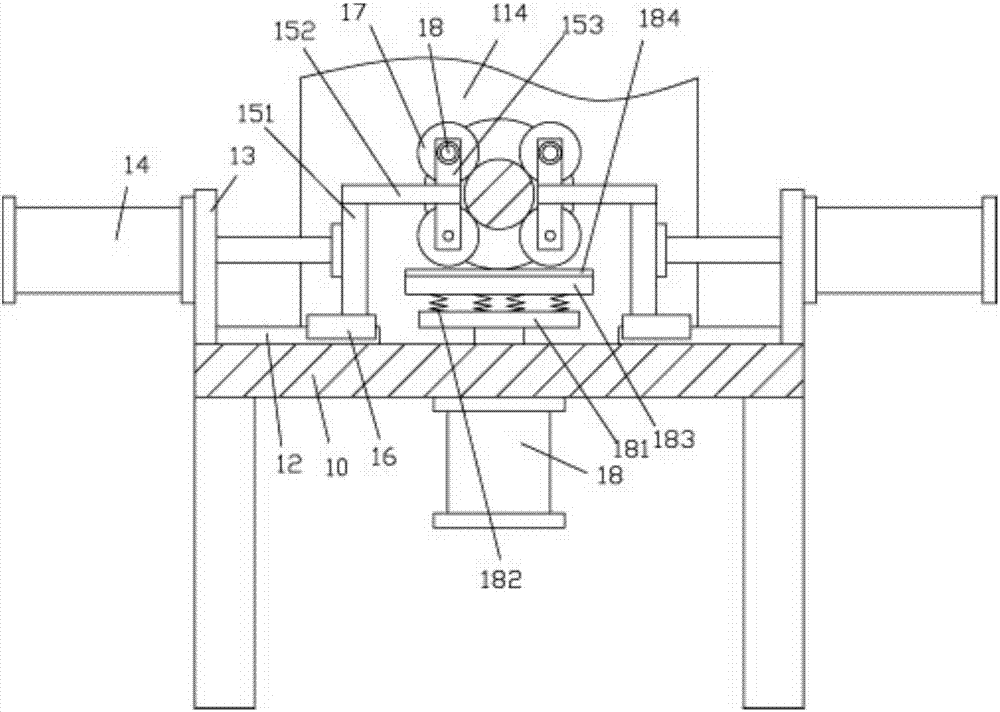

[0021] Examples, see e.g. Figure 1 to Figure 2 As shown, a fully automatic motor rotor cleaning machine includes a frame 10, the top surfaces of both sides of the top plate of the frame 10 are fixed with main side support plates 114, and the tops of the two main side support plates 114 are fixed on the top for cleaning On the bottom surface of the support plate 111, a rodless cylinder 112 is fixed on the middle part of the bottom surface of the upper cleaning support plate 111, and the push block of the rodless cylinder 112 is vertically downward and is fixed with an upper moving block 113, and the bottom surface of the upper moving block 113 is fixed with a support Frame 20, the top surface of the bottom plate of support frame 20 is fixed with telescopic cylinder 21, and the push rod of telescopic cylinder 21 passes the bottom plate of support frame 20 and is fixed with roller cleaning frame 22, is hinged with cleaning plush roller body in the roller cleaning frame 22 twenty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com