Rotary multipath fuse

A fuse and rotary technology, applied in the field of power facilities, can solve problems such as long overload response time and difficulty in meeting safety requirements, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

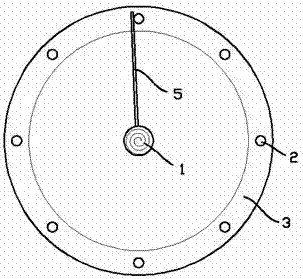

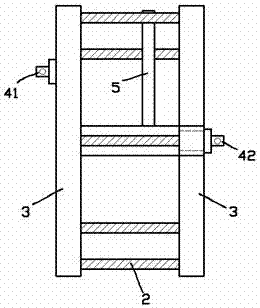

[0013] exist figure 1 , figure 2 In the first embodiment shown, the rotary multi-way fuse includes a clockwork shaft 1 that can rotate slowly as the mainspring is released. The main shaft of the clock and watch is formed, and will not be described in detail; with the clockwork shaft 1 as the central axis, there are 8 fuses 2 evenly distributed in the circumferential direction; the two ends of each fuse 2 are fixed by a circular bracket 3; and each fuse 2. The ends on one of the circular brackets 3 are commonly electrically connected to the first terminal 41; the clockwork shaft 1 is provided with a radially extending conductive rod 5, and the conductive rod 5 is unconstrained In the state, it can follow the clockwork shaft 1 to rotate; the conductive rod 5 is blocked by the fuse 2 and is pressed on a fuse under the elastic force of the clockwork shaft 1; the conductive rod 5 is electrically Connect to the second terminal 42 on the circular support 3 .

[0014] The above-me...

Embodiment 2

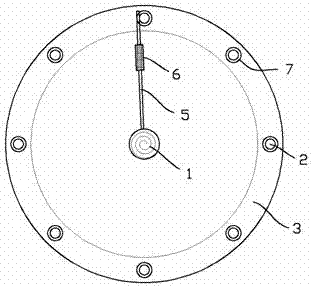

[0016] exist image 3 , Figure 4 In the shown second embodiment, different from the first embodiment, an electromagnet 6 is penetrated near the free end of the conductive rod 5, and each fuse 2 is sleeved with a short section that is not connected with the conductive rod 5. The iron pipe 7 in contact; thus, when a fuse 2 is blown, the free end of the conductive rod 5 gradually rotates before the next fuse, such as an arc occurs between the fuse 2 and the conductive rod 5 (on the conductive rod 5 slowly approaching the fuse 2, the possibility of arcing is greater), then the electromagnet 6 is switched on, and forms a magnetic attraction force with the iron pipe 7, so that the conductive rod 5 is quickly pressed against the fuse, so that the The arc is extinguished. Further, the conductive rod 5 is in the shape of a sheet, and the plane of the sheet is parallel to the fuse 2, so as to push a significant airflow to the fuse 2 in the process of rapidly approaching the fuse, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com