Electric heating kettle

A technology for an electric kettle and a kettle body, which is applied to water-boiling utensils, cooking utensils, household utensils, etc., can solve the problems of inconvenient cleaning of the electric kettle, unsanitary, easy to hide dirt, etc. Easy-to-clean, simple-to-craft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

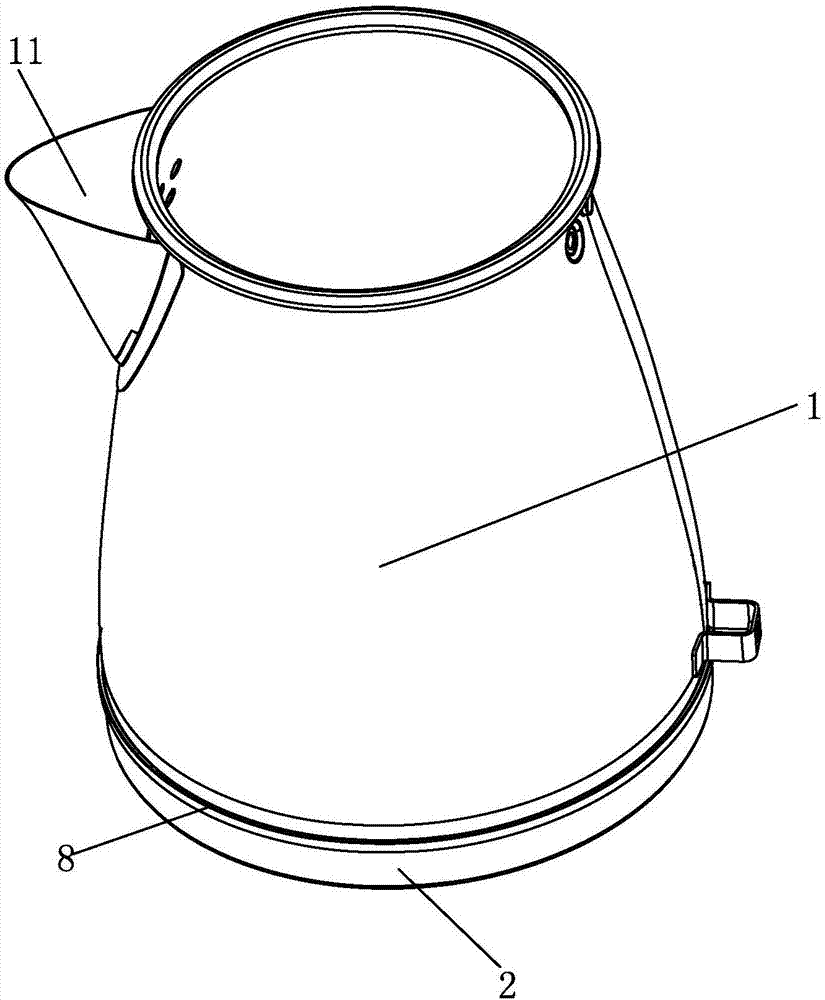

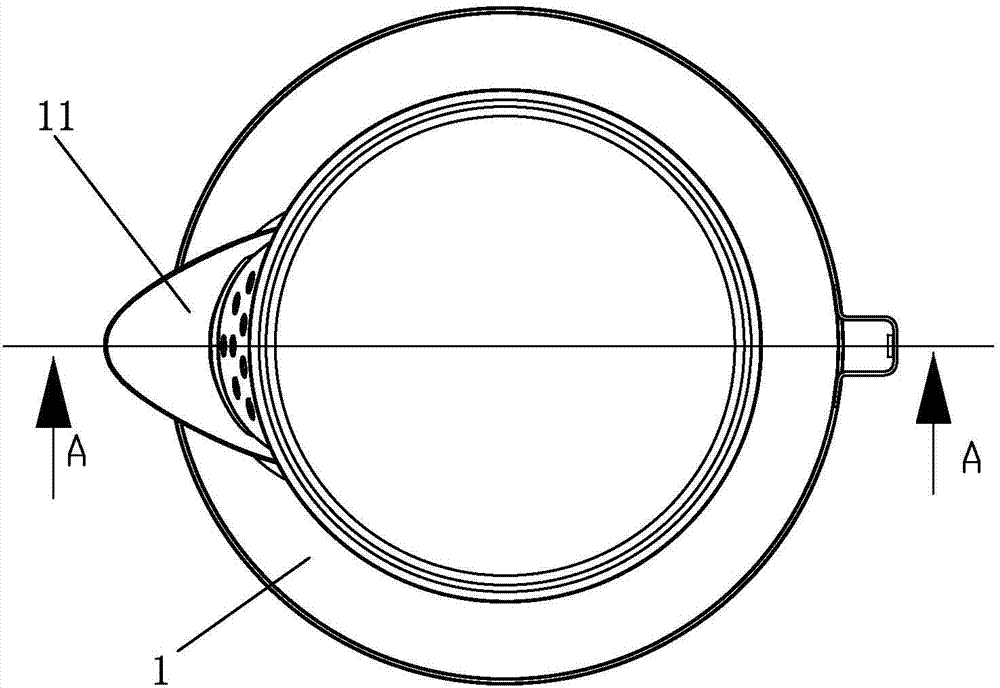

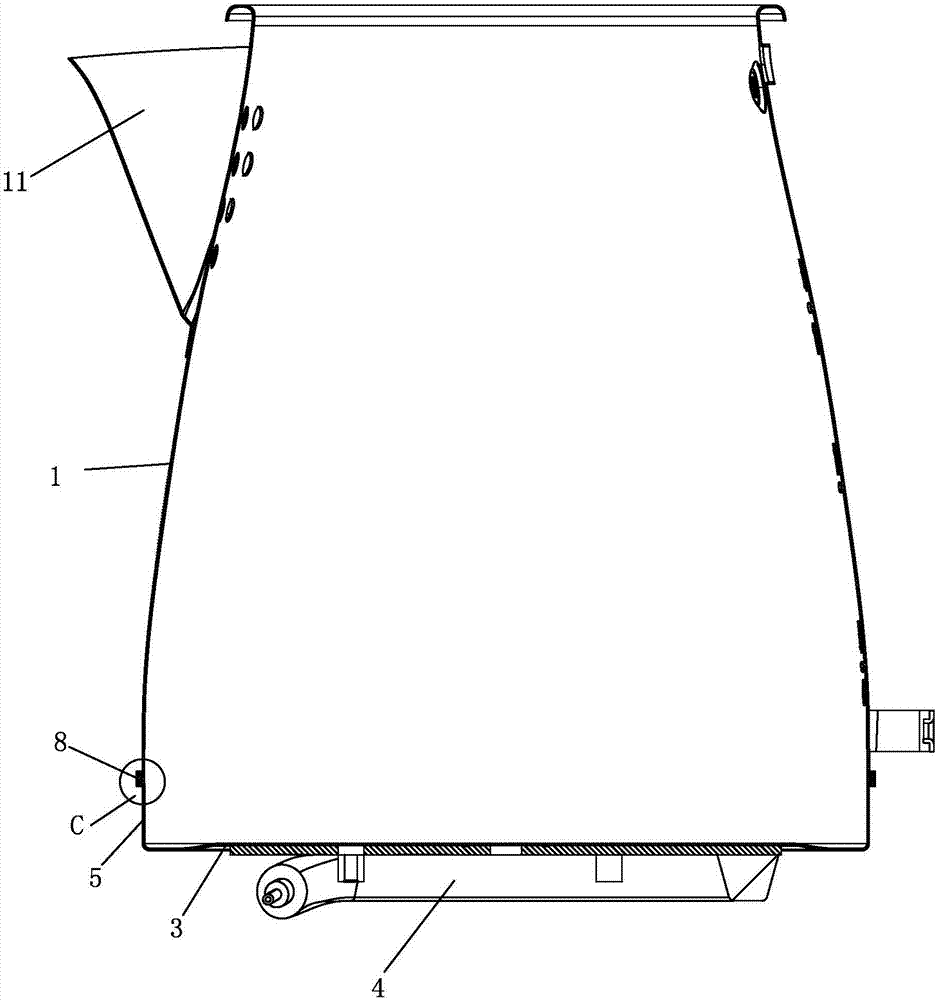

[0024] Such as figure 1 — Figure 4 As shown, an electric kettle includes a kettle body 1, a kettle bottom assembly 2 is connected to the lower part of the kettle body 1, the kettle bottom assembly 2 includes a kettle bottom plate 3, an electric heating device 4 is provided at the bottom of the kettle bottom plate 3, and the kettle bottom plate 3 The periphery extends upwards to form a lower edge 5 of the kettle body, and the lower edge 5 of the kettle body is connected with the main body 1 of the kettle body. In the present invention, the lower edge 5 of the kettle body is formed by extending the periphery of the bottom plate 3 upwards, and then fixed and sealed with the kettle body 1 to form the kettle body structure of the electric kettle, and the gap is moved upward so that the gap is formed on the edge of the kettle body, and the distance from the bottom edge of the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com