Oven stove

A technology for ovens and fire grills, applied in the field of ovens, can solve problems such as gas leakage, redness of the stove, inconsistent atmospheric pressure, etc., and achieve the effects of stable combustion, stable flame, and stable gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

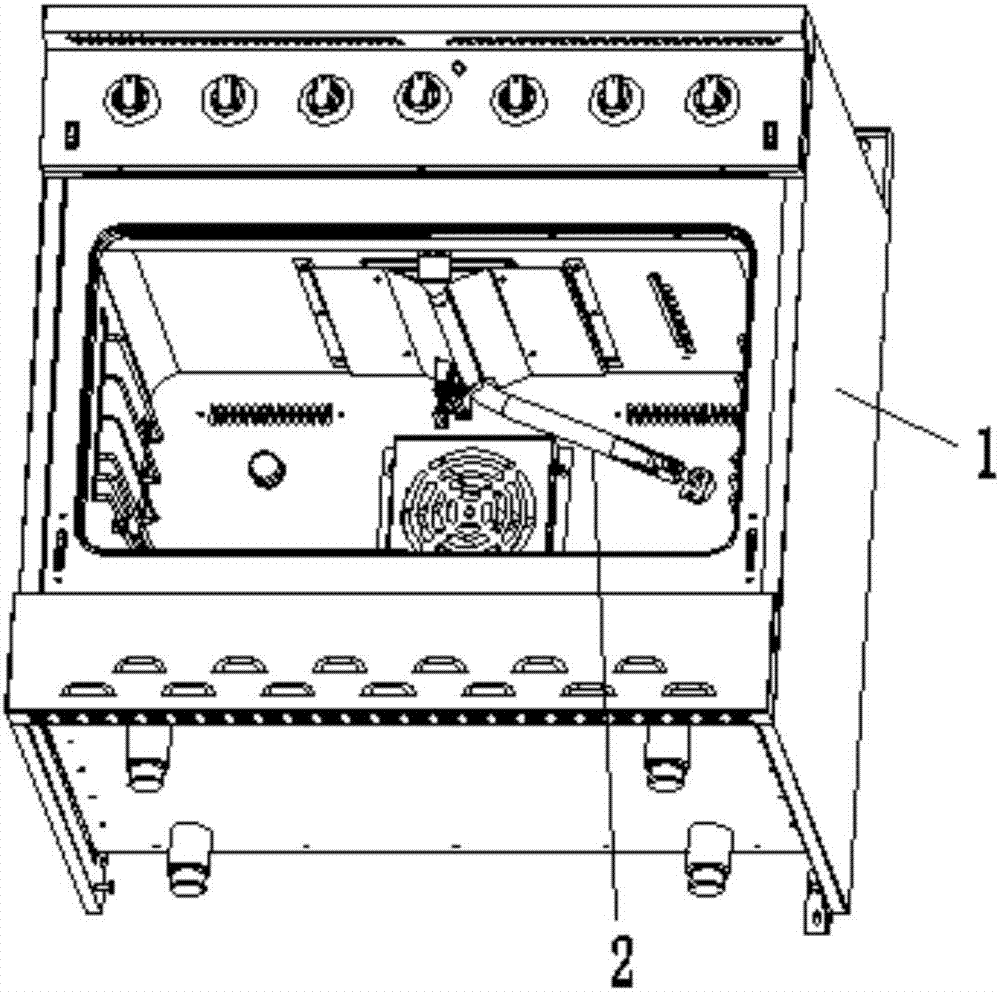

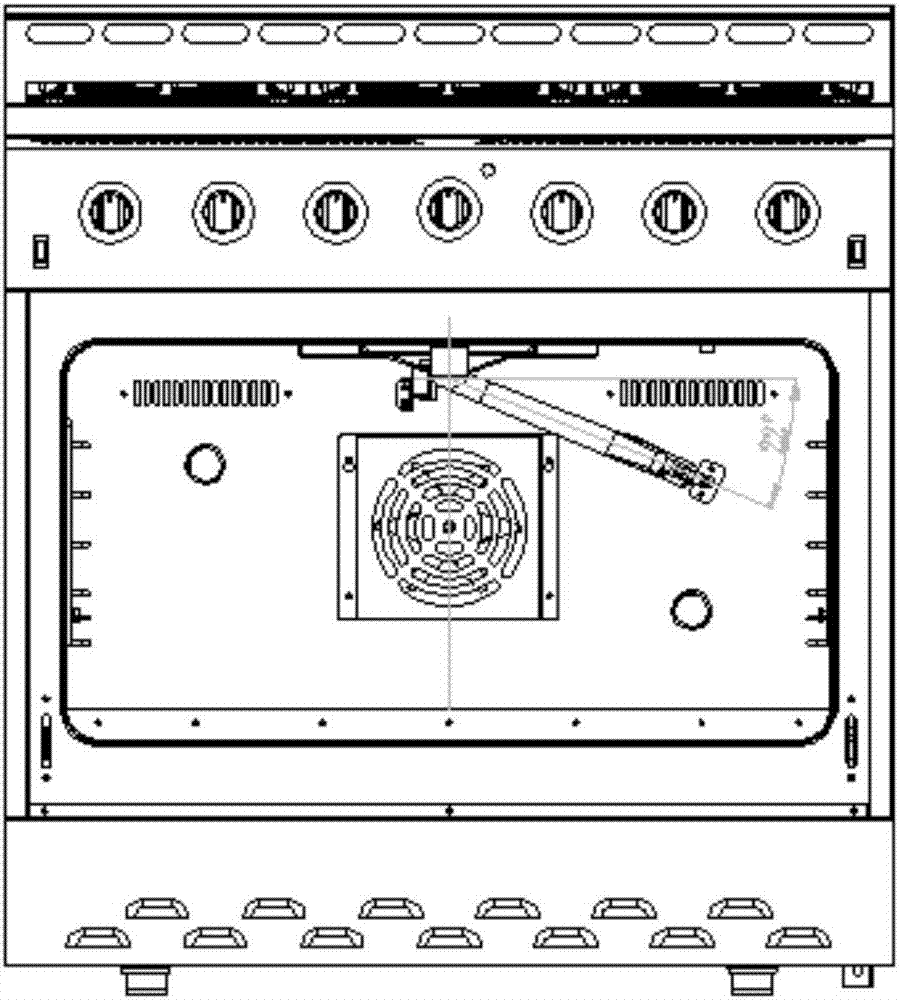

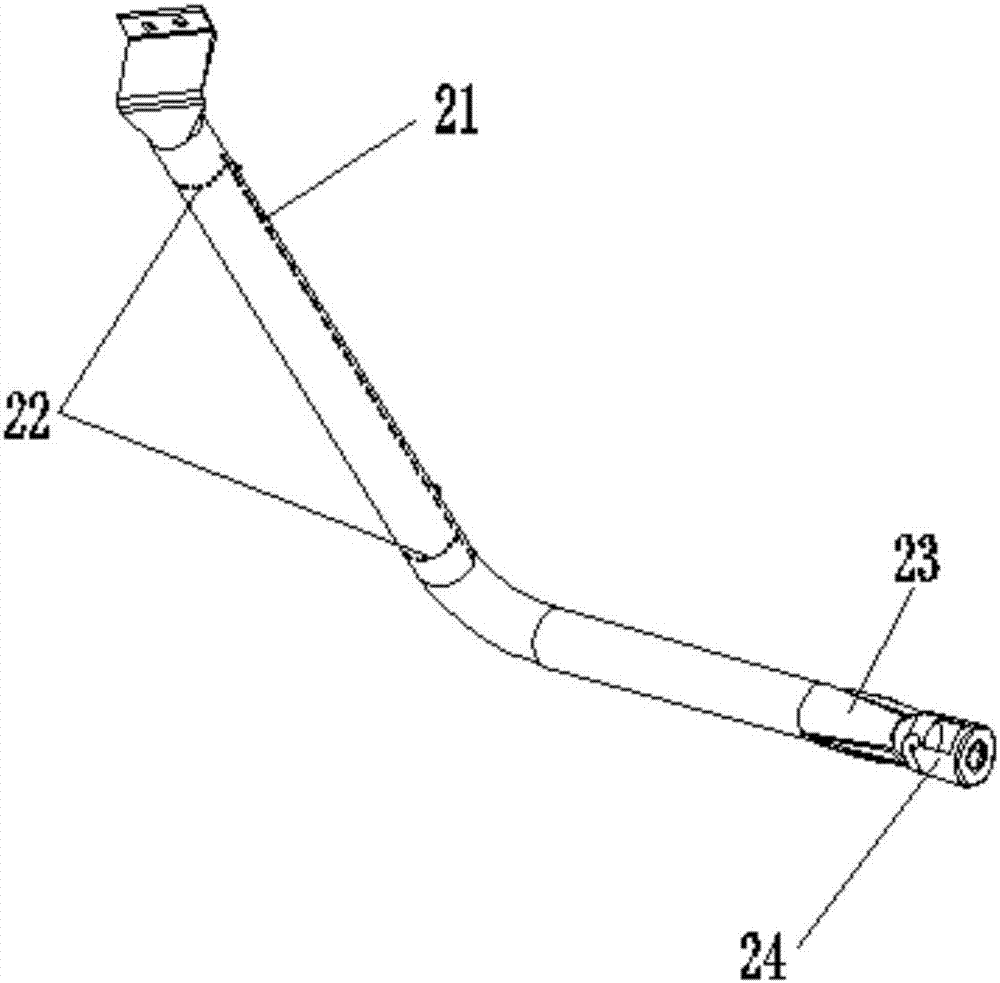

[0017] Such as Figure 1 to Figure 6 As shown, the present invention discloses an oven range, which includes an oven 1 and a fire row 2 , and the fire row 2 is arranged in the oven 1 . The fire row 2 is L-shaped, and one side of the fire row 2 is provided with several flame holes 21 and fire transmission holes 22. The flame holes 21 are distributed along the axial direction of the side on the fire row 2, and the fire transmission holes 22 Distributed along the circumferential direction of the side on the fire row 2; the end of the other side of the fire row 2 shrinks inward and forms a throat 23, and the end of the throat 23 is connected with a damper 24. Throat 23 is to form negative pressure after the gas flow is injected into the fire row from the nozzle, thereby introducing primary air to fully mix the gas and air. Damper 24 is used for regulating the primary air...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap