3D printer based on mixed coordinate system

A 3D printer and mixed coordinate system technology, applied in the 3D field, can solve problems such as inconvenient leveling and poor printing effect, and achieve the effects of high cost performance, convenience improvement, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

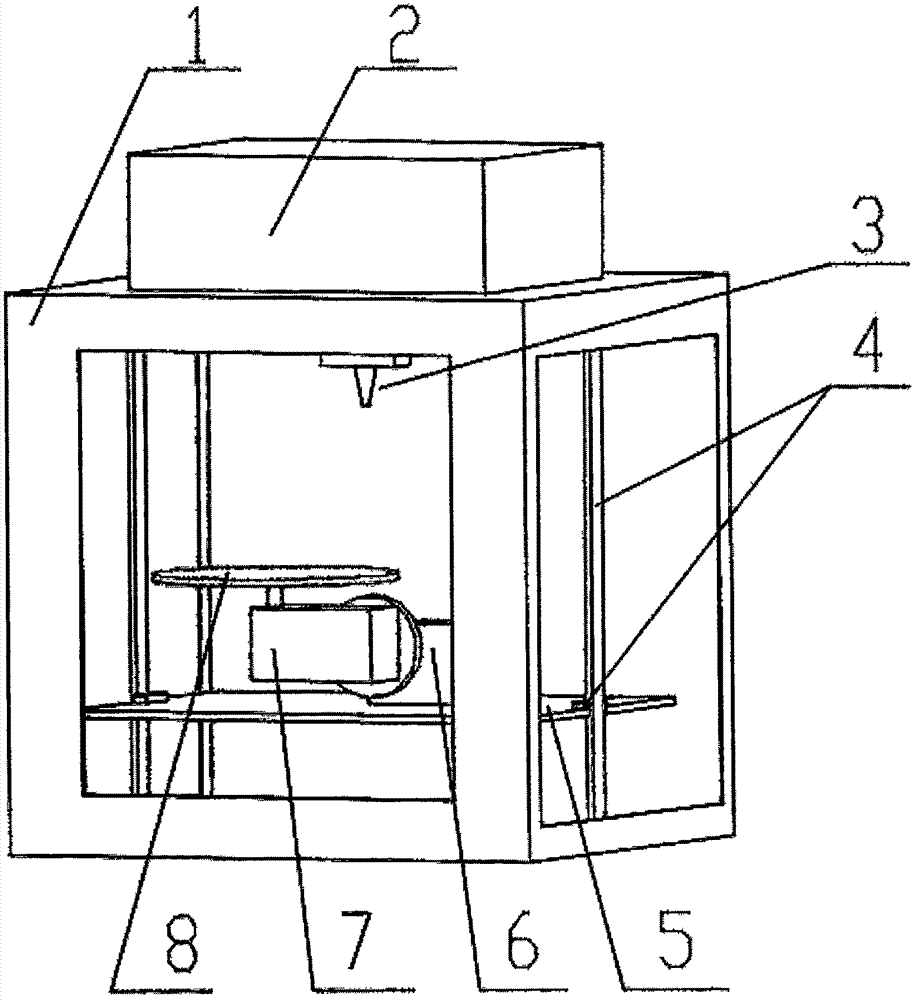

[0011] Such as figure 1 As shown, the control box 2 is fixed on the top surface of the aluminum frame 1 by screws; the wire discharge nozzle 3 is fixed on the top of the aluminum frame 1 by screws; the guide rail slider 4 is fixed on the inside of the aluminum frame 1 by screws, responsible for controlling The lifting of the lifting platform 5; the X-Z plane rotating turntable 6 is fixed on the lifting platform 5 by screws; the X-Y plane rotating turntable 7 is fixed on the X-Z plane rotating turntable 6 by screws; the heating bed 8 is fixed on the X-Y plane rotating turntable 7 by screws; The position of the printing and forming point on the hot bed 8 is achieved through the lifting of the lifting platform 5, the rotation of the X-Z plane rotating turntable 6, and the rotation of the X-Y plane rotating turntable 7, so that the printing and forming point corresponds to the position of the filament nozzle 3, and the printing and forming point Reach any point in the space coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com