Flat mop cleaning body structure

A main structure, flat mopping technology, applied in the direction of cleaning carpets, floors, cleaning equipment, etc., can solve problems such as laborious pressing of the mop bar, cleaning, and difficult-to-clean parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

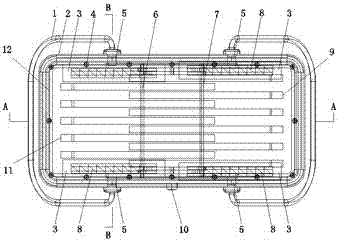

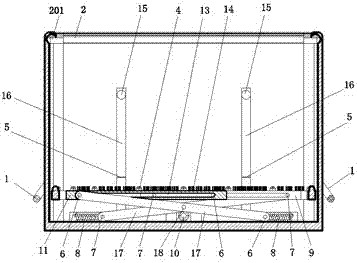

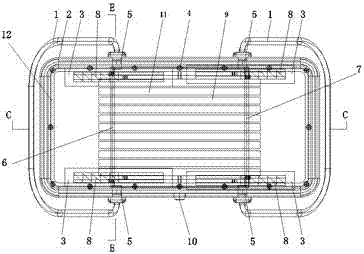

[0049] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10, a flat drag cleaning main structure, including a flat drag cleaning main structure, including a bucket 2, a support member 17 with a lifting device, a washing frame 12, a guide groove 201 / 3 / 16, a spring 8, and a locking device 5 The positioning bayonet 501, the roller 801, the washboard 9 / 11 of the cleaning device at least one, the mop plate 19 of the transmission mechanism, the bucket 2 has an opening to accommodate the lifting device, the locking device 5, the cleaning device, the mop plate 19 of the transmission mechanism, the row The liquid port, the piston part 10, and the handle 1 are characterized in that: the inner end of the opening of the barrel 2 is provided with a fluid guide groove 201, and the inner wall of the barrel 2 is evenly provided with at least one relative guide groove 16. The inner upper end of the guide groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com