Automobile air filter structure

An air filter and air filter technology, which is applied in the direction of fuel air filter, intake muffler, combustion air/combustion-air treatment, etc., can solve the problem of no change in the cross section of the intake pipe and the failure to effectively increase the acoustic impedance , without considering the height of the body, etc., to achieve the effect of favorable space layout, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

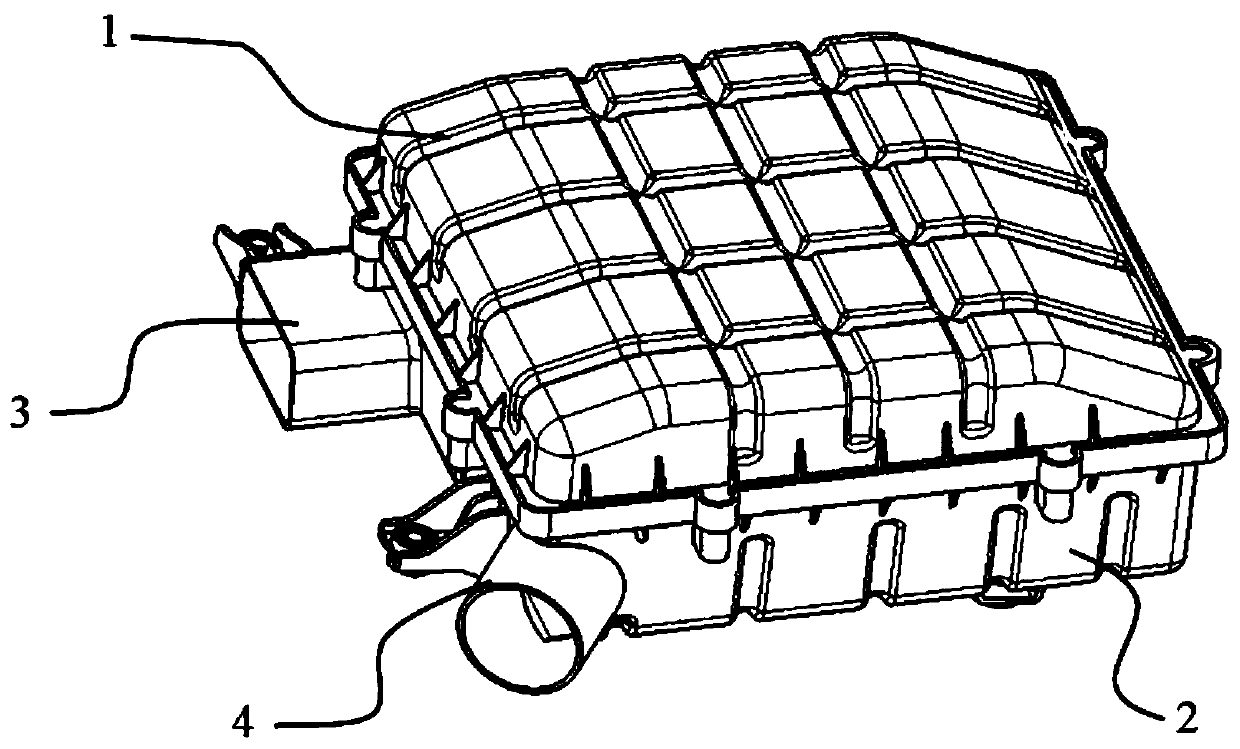

[0029] like figure 1 As shown, the automobile air filter includes an upper air filter housing 1 and a lower air filter housing 2. The upper air filter housing 1 and the lower air filter housing 2 are connected by eight corresponding bolt holes, and each side is connected by two bolt holes. Bolt holes are secured.

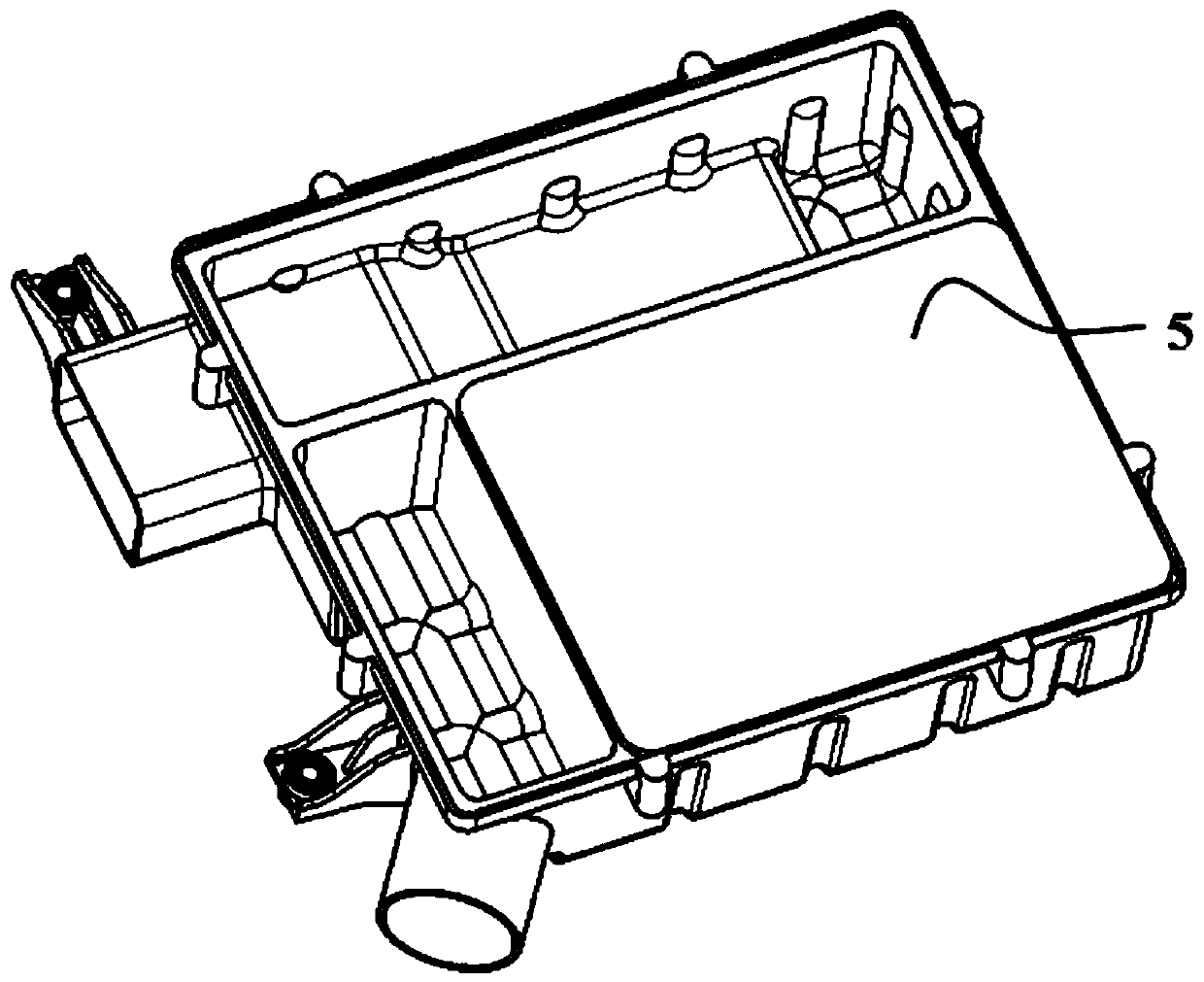

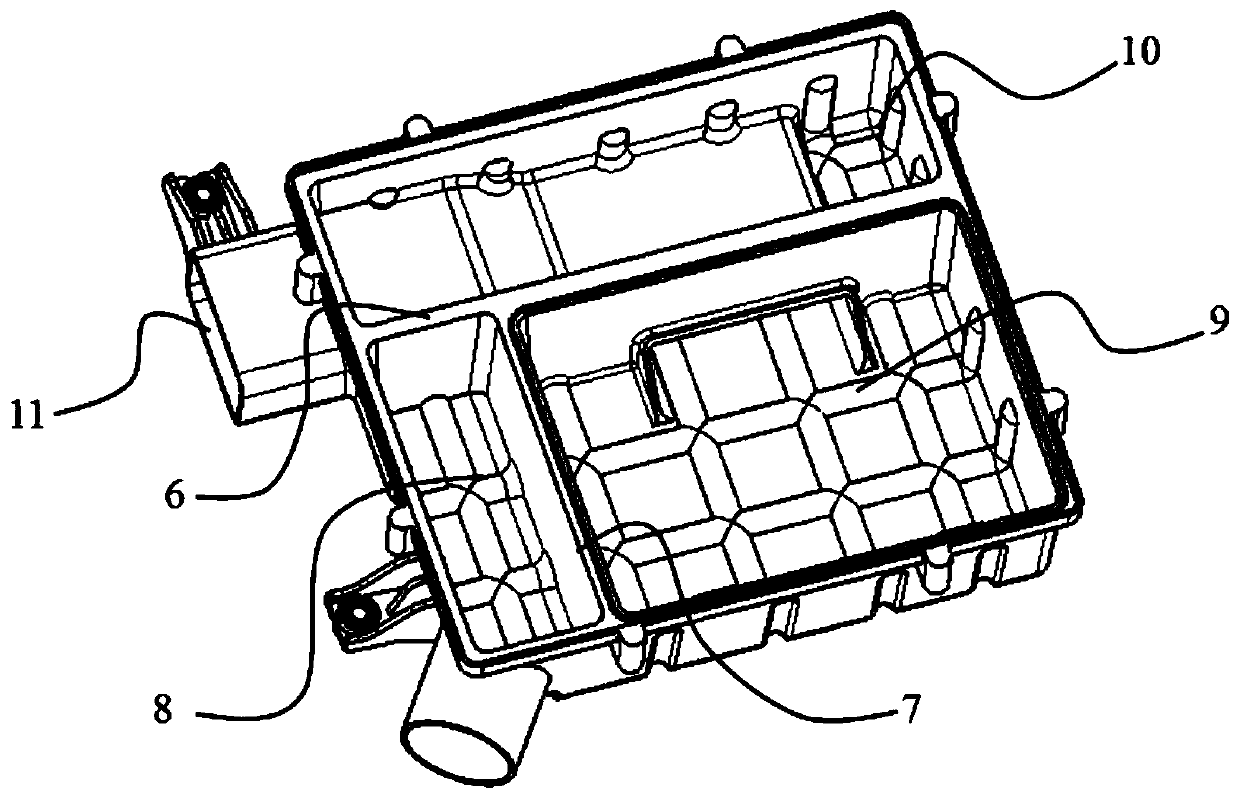

[0030] like figure 2 , 3 The shown air filter lower housing 2 is divided into a resonant cavity 10, a filter chamber 9 and an air outlet chamber 8 by a longitudinal partition plate 6 and a transverse partition plate 7, that is, the air filter lower housing 2 is separated by a longitudinal partition plate 6 , wherein the part with a smaller area is the resonant cavity 10, and the part with a larger area is divided into a filter chamber 9 and an air outlet chamber 8 by a transverse partition plate 7. Air enters through the air filter air inlet 3 and passes through the air inlet chamber 11 , the resonant cavity 10 , the filter chamber 9 , and the air outlet chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com