Combined type heating element capable of heating small amount of resin

A combined heating body technology, applied in the direction of ohmic resistance heating, heating element shape, electric heating device, etc., can solve the problem of not being able to heat a small amount of resin, and achieve the effect of weight reduction and light use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further elaborate the specific embodiment of the present invention below in conjunction with accompanying drawing, working principle:

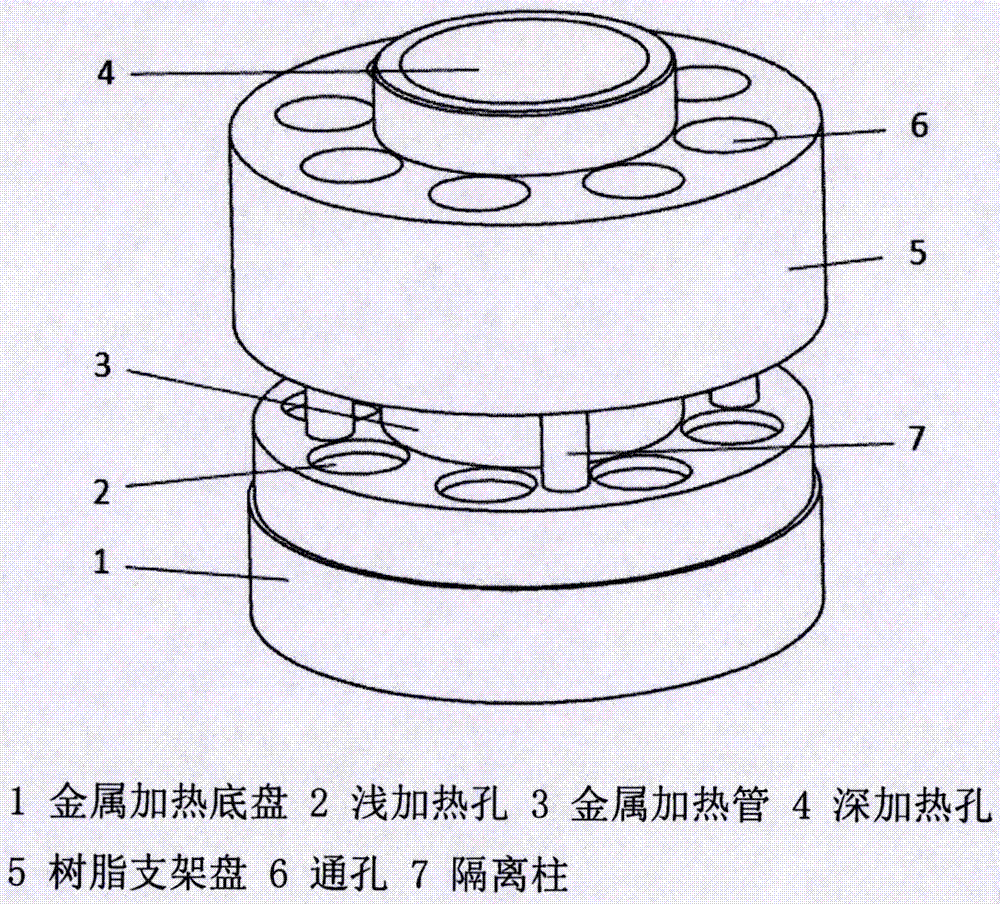

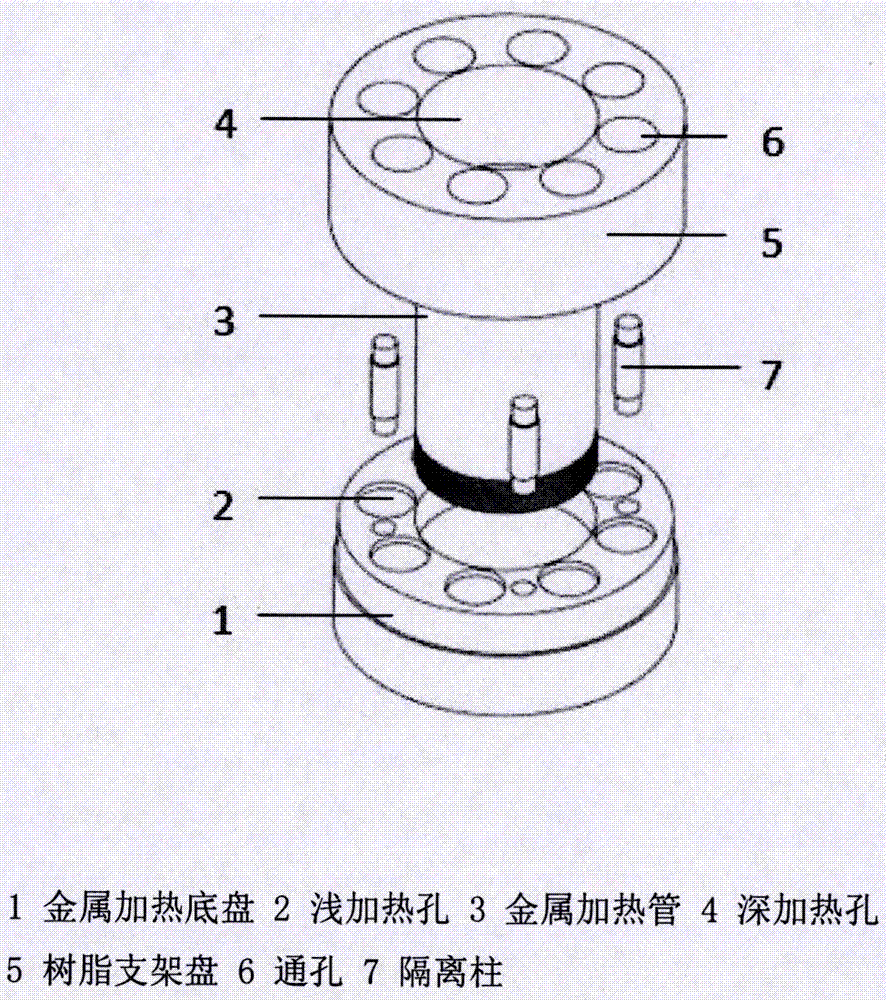

[0022] Such as figure 1 The metal heating chassis 1 is generally circular, and there are several shallow heating holes 2 in the center and the periphery. The metal heating tube 3 is a section of metal round tube, and the lower end is fixedly connected to the shallow heating hole 2 in the middle of the metal heating chassis, thus forming a Deep heating hole 4, the upper end of the metal heating tube 3 is connected to the resin support plate, the shape of the resin support plate 5 is similar to the metal heating chassis 1, and the center and periphery are a plurality of circular through holes 6, which are connected to the metal heating chassis The shallow heating hole 2 on 1 is vertically corresponding. The metal heating chassis 1 and the resin support plate are connected by metal heating pipes 3 , and there is a certain distance in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com