Hairstyling appliance having integrated thermal insulation means

A technology of equipment and fixing mechanism, which is applied in the direction of hairdressing equipment, curling irons, hot clips, etc., and can solve problems such as temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

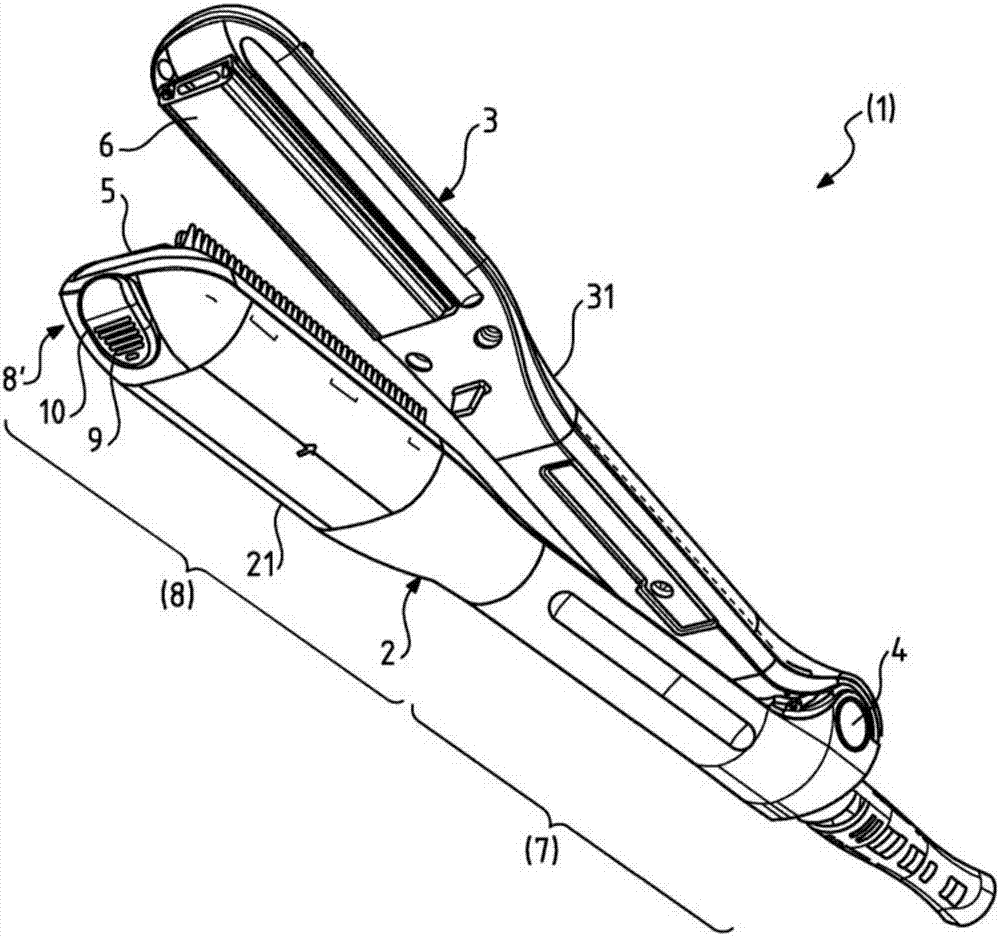

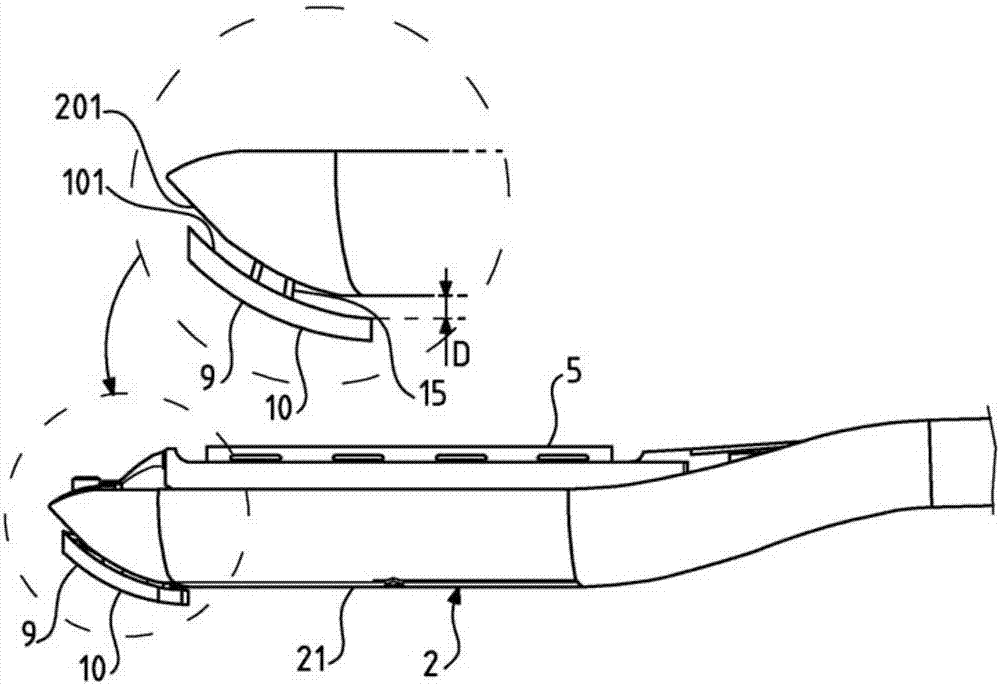

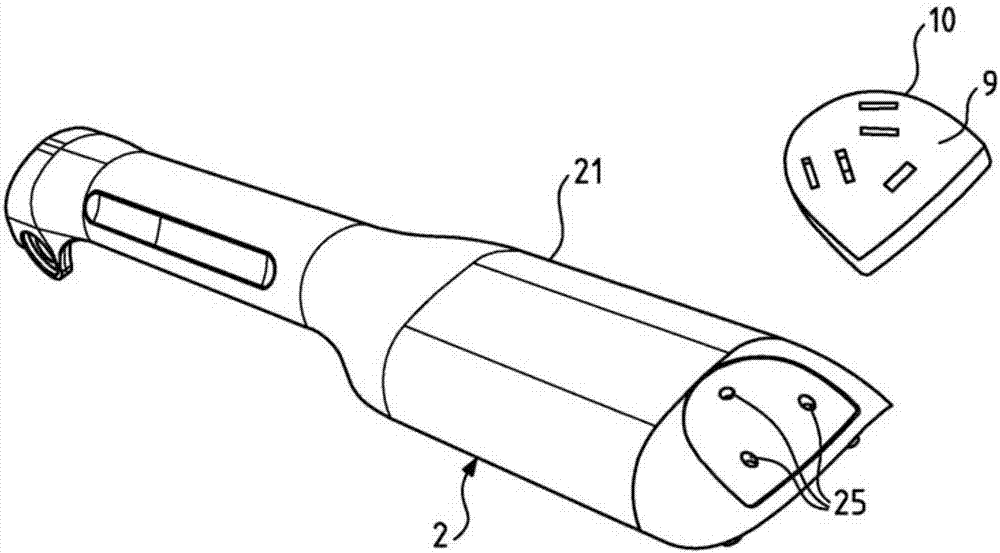

[0032] Such as figure 1 As shown, the hairdressing appliance 1 is of the straightener type and comprises two arms 2, 3 which are pivotally articulated to each other by means of a pivot connection 4 of the hinge type. Thus, the two arms 2, 3 constitute a clamp which allows an angular separation between the two arms 2, 3, or a closeness of the two arms 2, 3 to each other, in order to allow clamping. Tightly set the hair between the two arms 2,3.

[0033] Said arms 2, 3 each comprise a housing 21, 31 and a heating system. In addition to an electric heating mechanism (not shown) and a thermal control and regulation mechanism (not shown), these heating systems each include a heating plate 5, 6 having features such as figure 1 The shape of the flat surface shown. These flat heating surfaces are arranged on the inner faces of the arms 2,3. Thus, when clamped, the two flat heating surfaces are positioned opposite each other and at the same time allow to achieve a thermal treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com