Apparatus for cooling the adhesive applied to the surface of the pouch

A technology for cooling surfaces and adhesives, applied in the field of adhesive devices, which can solve problems such as the production rate of bottom bags that are not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

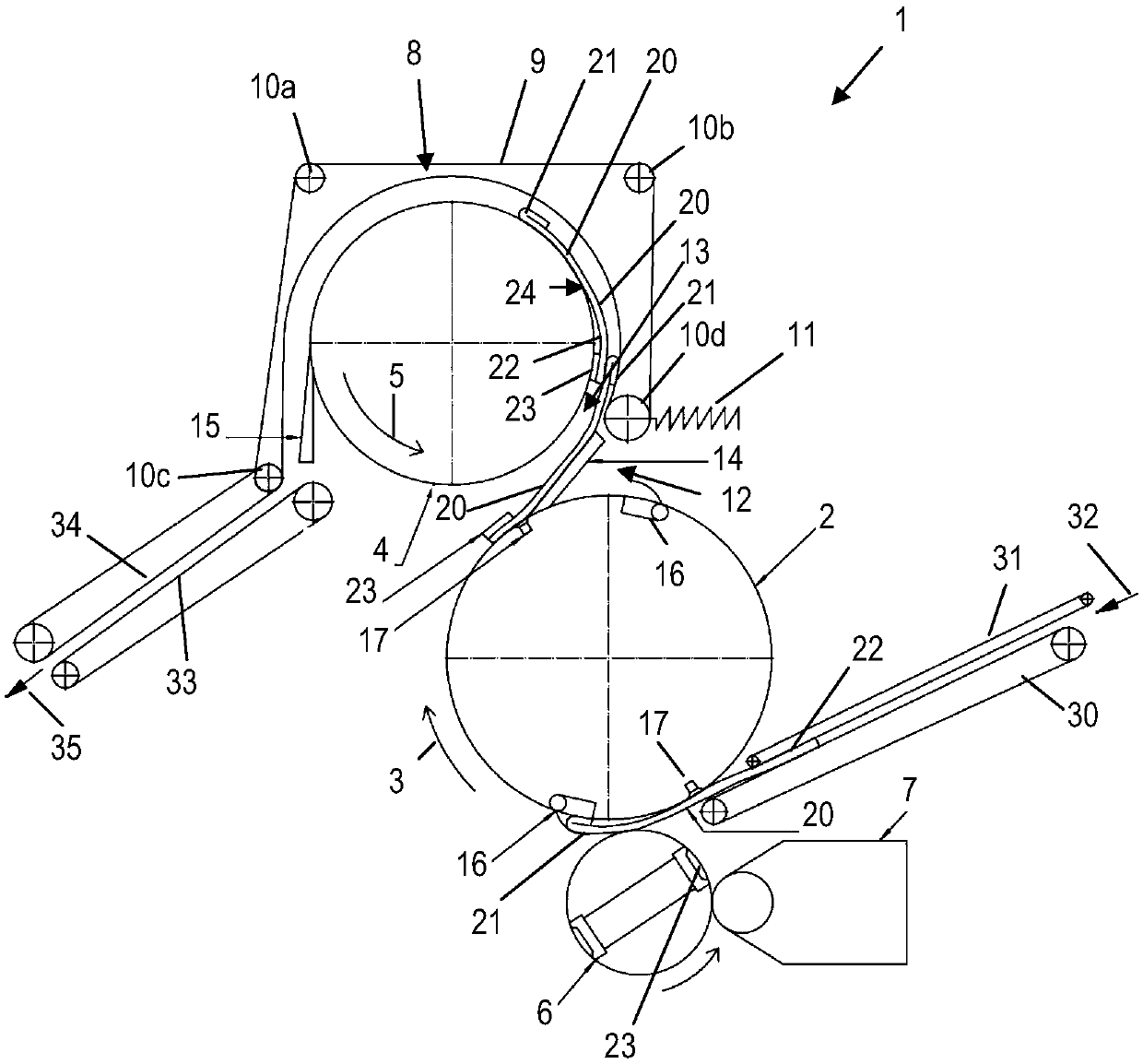

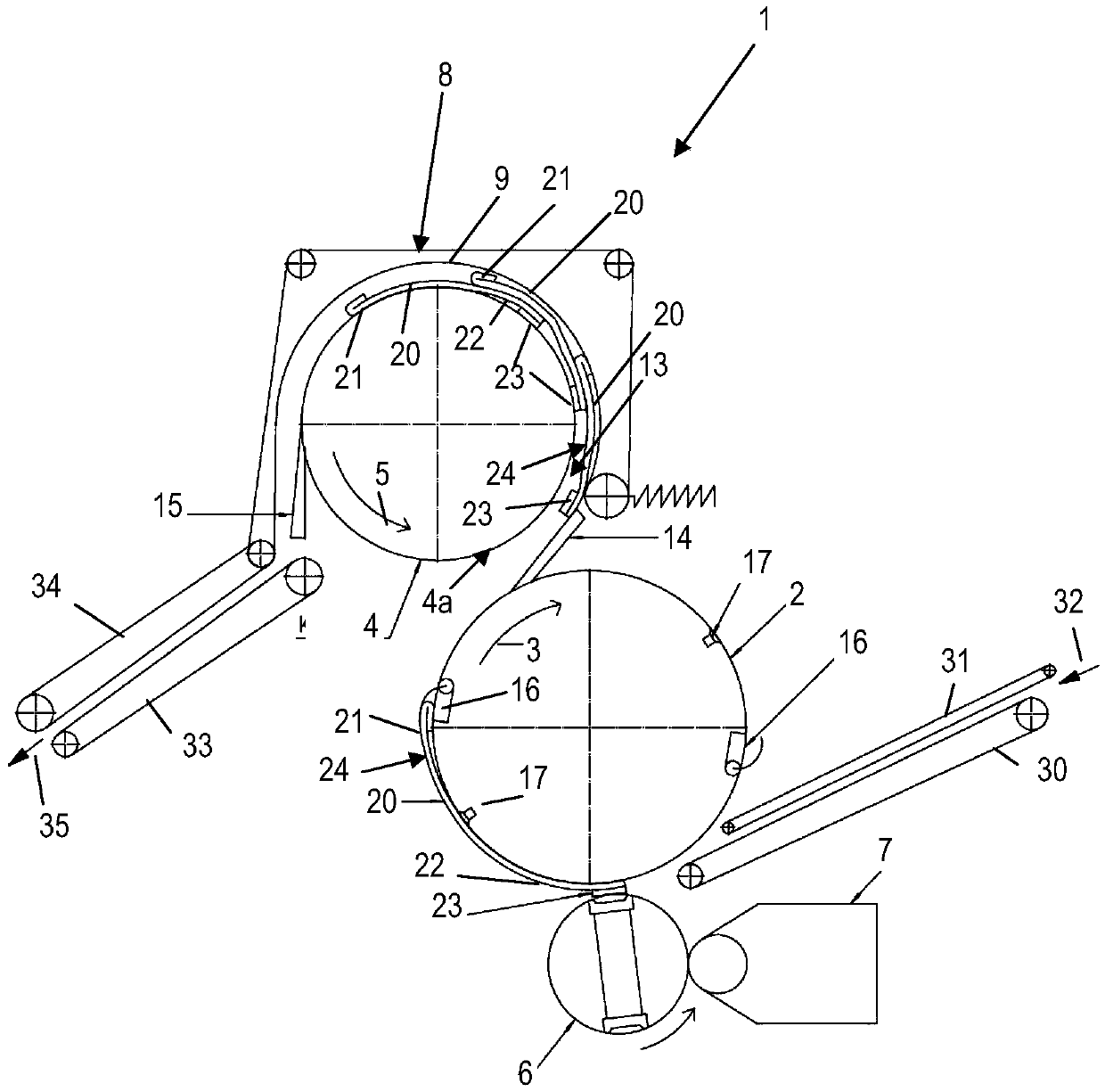

[0031] In the manufacture of bottom bags, side gussets are formed at tube sections formed from flat webs glued together longitudinally or from tube fabrics. Subsequently, at one end of the pipe section, the so-called "factory end" 21, the clamped bottom surface is formed by turning the pipe end over approximately 180° along the fold line and joining / gluing it to the pipe wall, where the so-called "factory end" 21 "21 represents the bottom end and thus the bottom surface in the filled bag. In the bag 20 thus produced, the application of the reactivatable adhesive 23 is then carried out on the bag surface 24 near the open end of the bag 20 . This open end is called the "user end" 22 and remains open when the bag is delivered to the customer. The customer then fills the bag with product, typically a bulk material such as animal feed, and closes the bag after filling by reactivating the adhesive 23 and folding the open end of the bag 20 over the adhesive 23 . The filled bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com