Method and apparatus for producing multifilament yarn

A technology of multifilament yarn and equipment, applied in the field of equipment for implementing the method, can solve the problems of reduced tensile strength, reduced yarn quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

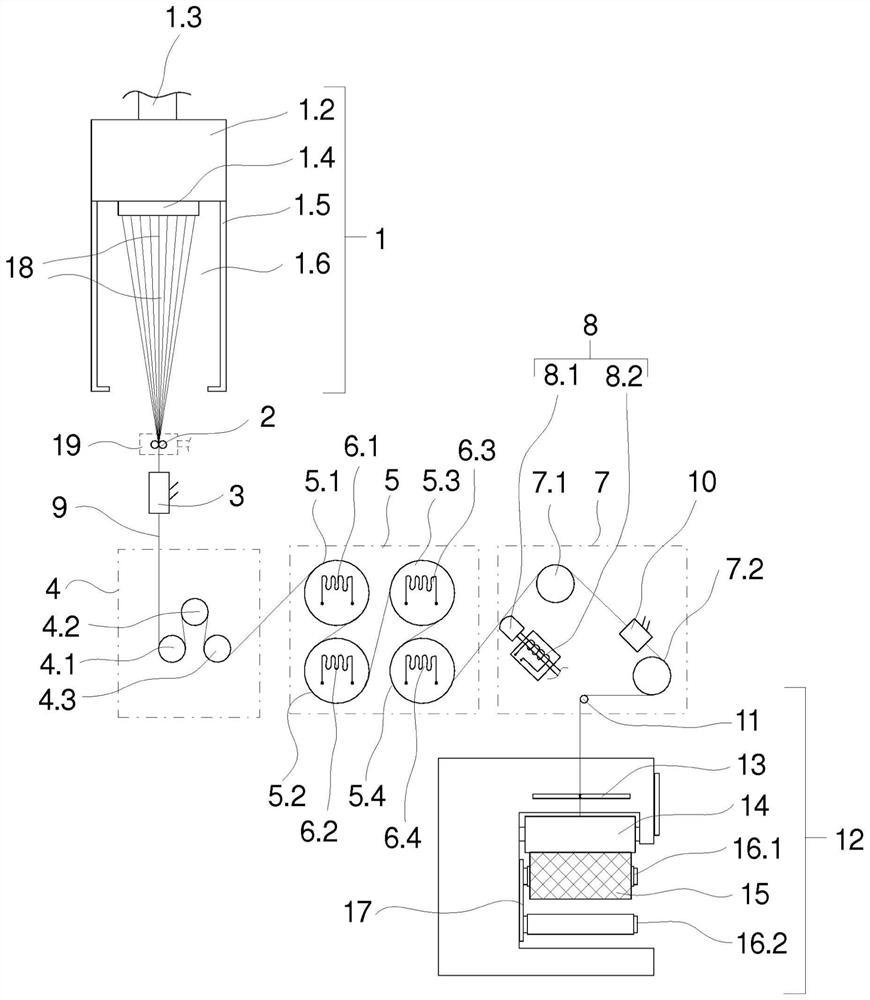

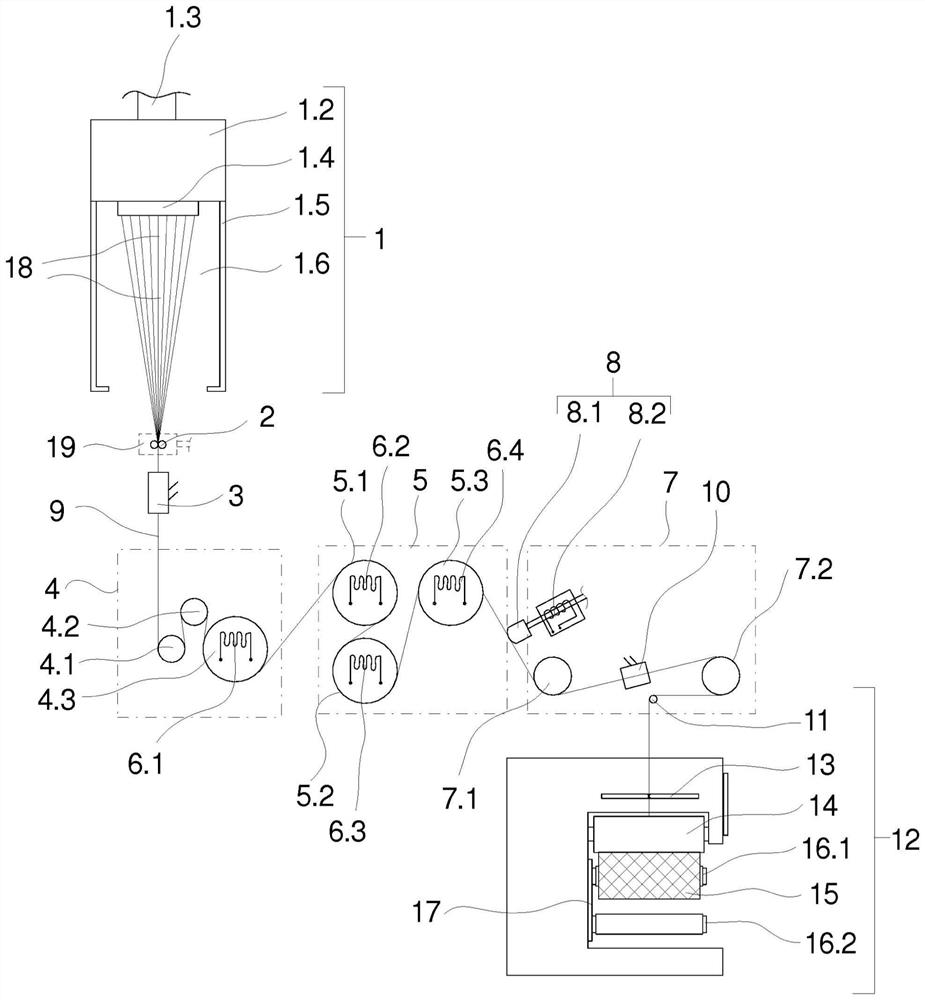

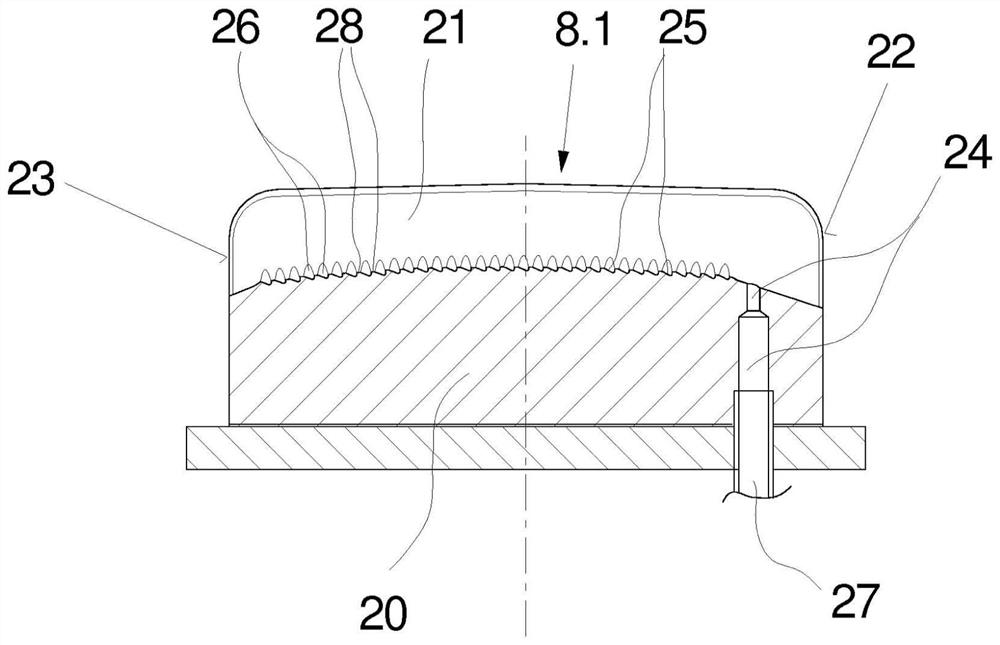

[0022] figure 1 A first exemplary embodiment of an apparatus according to the invention is schematically shown for carrying out the method according to the invention for producing multifilament yarns from polymer melts. The exemplary embodiment has a spinning arrangement 1 comprising a spinning beam 1.2 and a cooling device 1.5 arranged below the spinning beam 1.2. The spin beam 1.2 has on its underside a spinning nozzle 1.4 which is connected to a melt supply inlet 1.3 via a spinning pump (not shown here in more detail). The cooling device 1.5 forms a cooling channel 1.6 below the spinning nozzle 1.4. Cooling air is blown into the cooling channels 1.6, wherein the cooling air can be supplied as so-called cross-flow blowing or radially outside-to-inside blowing.

[0023] Arranged below the spinning device 1 is a polymerizing yarn guide 2 which is arranged concentrically to the spinning nozzle 1.4 and polymerizes a plurality of filaments 18 which have been extruded from the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap