Nozzle-position-adjustable sand blasting machine

A sand blasting machine, adjustable technology, applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve the problems of insufficient adaptability to different workpieces, time-consuming and labor-intensive, and large investment in tooling costs, and achieve small sliding friction, firm fixation, Ease of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

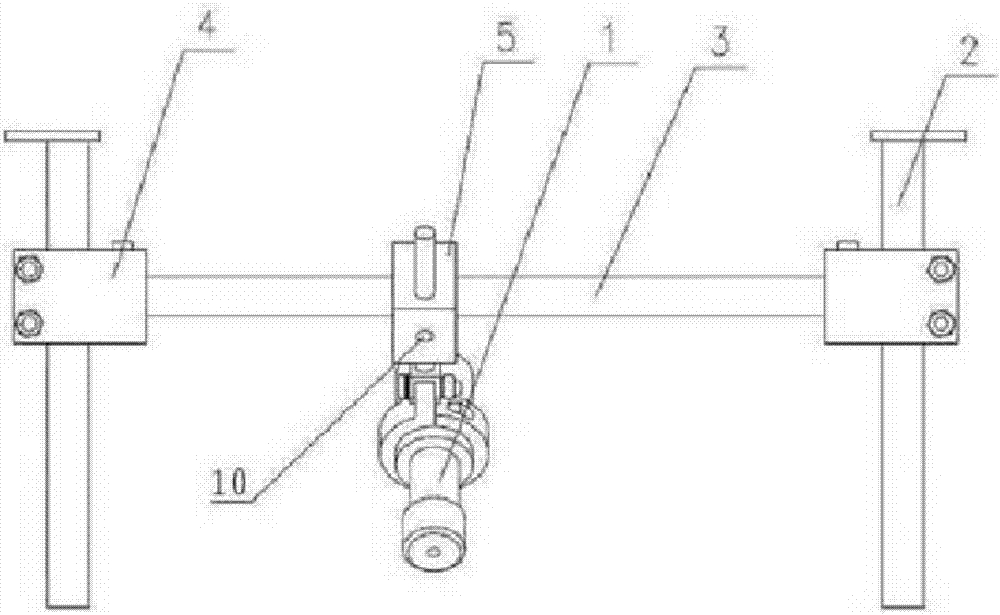

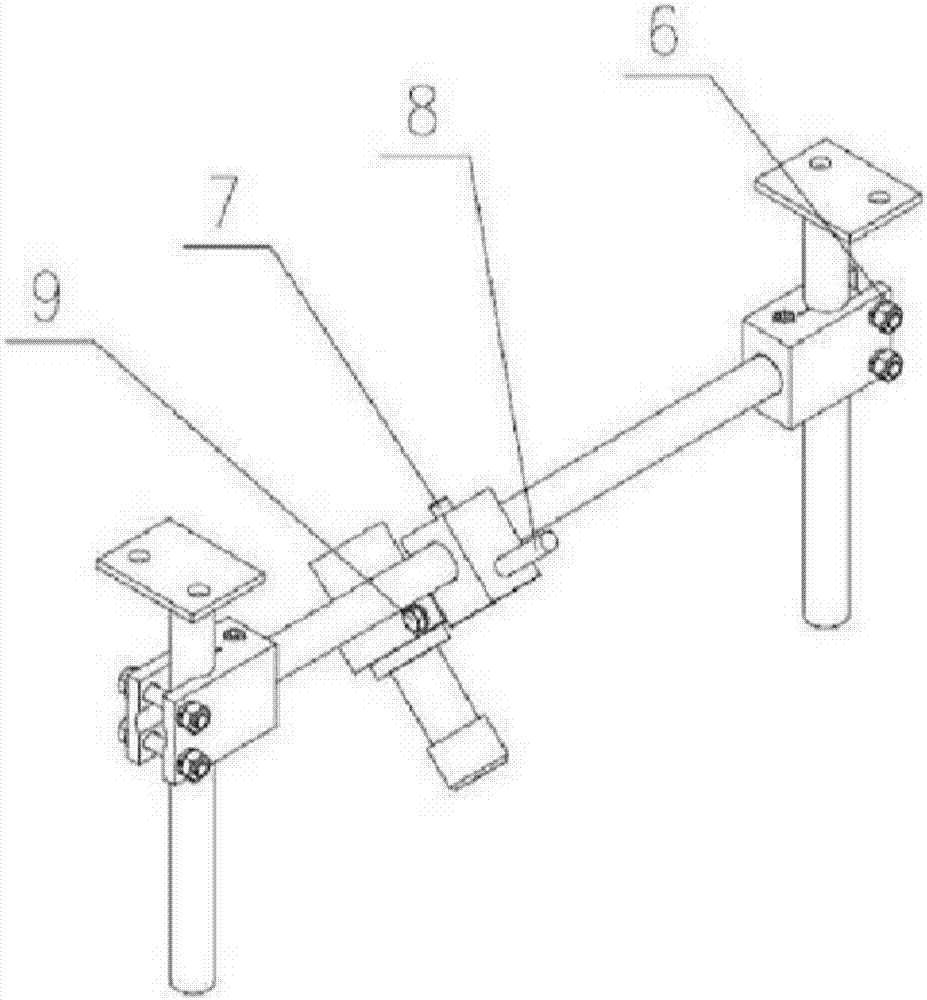

[0017] Example 1 consists of Figure 1-2 It can be seen from the illustrated embodiment that this embodiment includes a nozzle 1 located in the chamber of the sandblasting machine, the nozzle 1 is connected to the inner wall of the chamber through a nozzle position adjustment mechanism, and the nozzle position adjustment mechanism includes two cylindrical vertical sliding guide rails 2 arranged side by side and a cylindrical horizontal sliding guide rail 3, one end of two vertical sliding guide rails 2 is fixed to the inner wall of the chamber, and the two ends of the horizontal sliding guide rail 3 are connected to the vertical sliding guide rail through the first slider 4 matched with the vertical sliding guide rail 2 respectively. 2 Sliding connection, a locking and positioning device is provided on the two first sliders 4: the first slider 4 is provided with an opening sliding hole matching the cylinder, and a locking locking device is provided at the opening end of the ope...

Embodiment 2

[0018] Embodiment 2 The basic structural principle of Embodiment 2 is the same as that of Embodiment 1, except that the direction is adjusted, and no drawings are shown here.

[0019] Including the nozzle located in the chamber of the sand blasting machine, the nozzle is connected with the inner wall of the chamber through the nozzle position adjustment mechanism, the nozzle position adjustment mechanism includes a cylindrical vertical sliding guide rail and two cylindrical horizontal sliding guide rails arranged side by side, and the two horizontal sliding guide rails One end is fixed to the inner wall of the chamber, and the two ends of the vertical sliding guide rail are slidingly connected with the horizontal sliding guide rail through the first slider matched with the horizontal sliding guide rail respectively, and locking and positioning devices are provided on the two first sliders ; The locking and positioning device on the first slider includes: the first slider is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com