Cement mortar stirring device improving stirring effect

一种水泥胶砂、搅拌装置的技术,应用在水泥搅拌装置、黏土制备装置、售卖原料供应装置等方向,能够解决影响搅拌效果、原料倾倒出来、环境污染等问题,达到提高搅拌效果、安装拆卸方便、提高均匀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

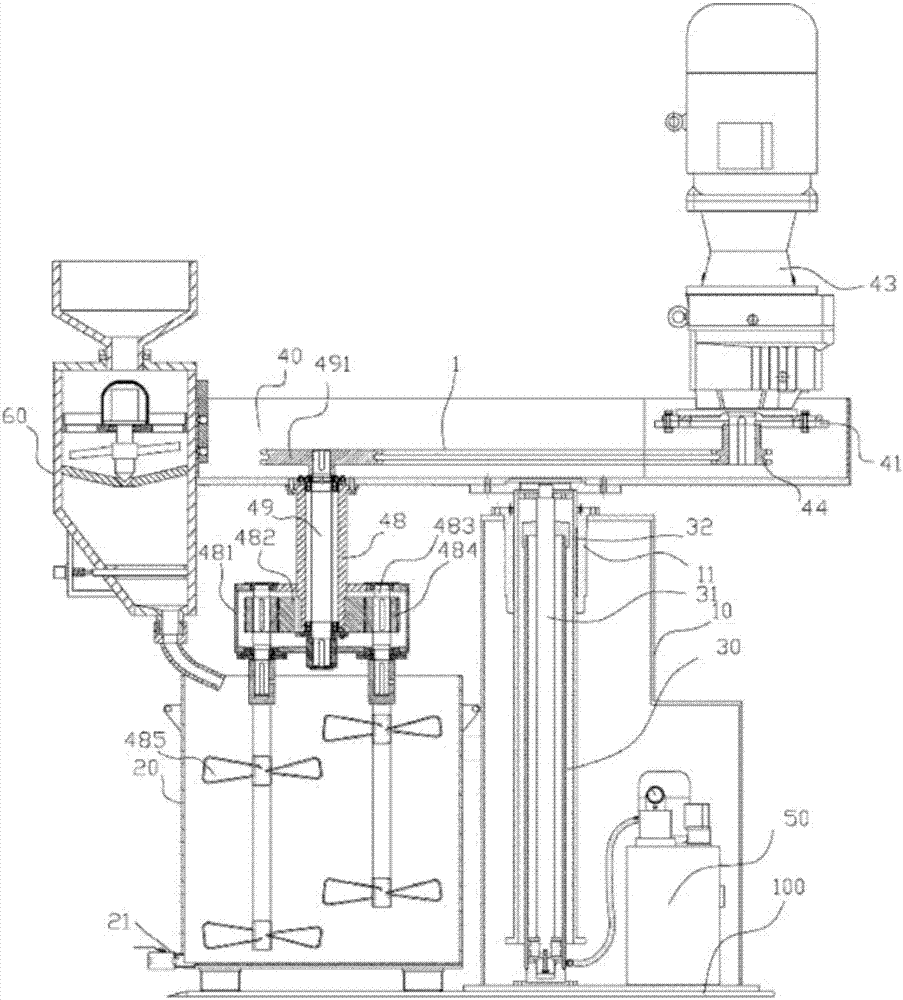

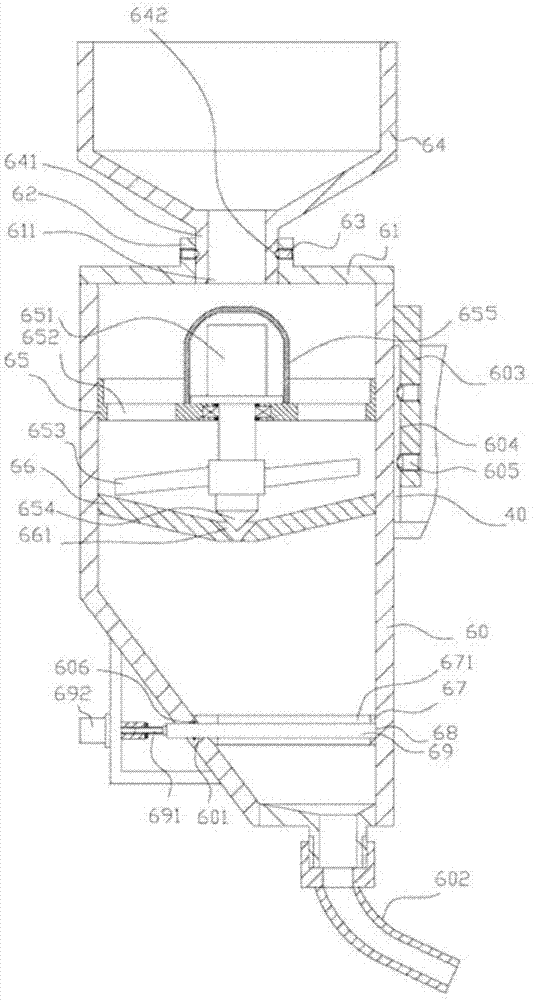

[0022] Example, see as Figure 1 to 3 As shown, a cement mortar mixing device includes a frame 10 and a mixing barrel 20. The top of the frame 10 is fixed with a connecting sleeve 11, and the frame 10 is provided with a pushing cylinder 30, which pushes the pushing rod in the cylinder 30 A push sleeve 32 is fixed on 31, the top surface of the push sleeve 32 is fixed on the upper fixed cover 40, the push sleeve 32 is inserted into the connecting sleeve 11, and the right side of the upper fixed cover 40 is fixed with a support plate 41. A drive motor 43 is fixed on the support plate 41, and the output shaft of the drive motor 43 vertically passes through the support plate 41 and is fixed with a drive wheel 44;

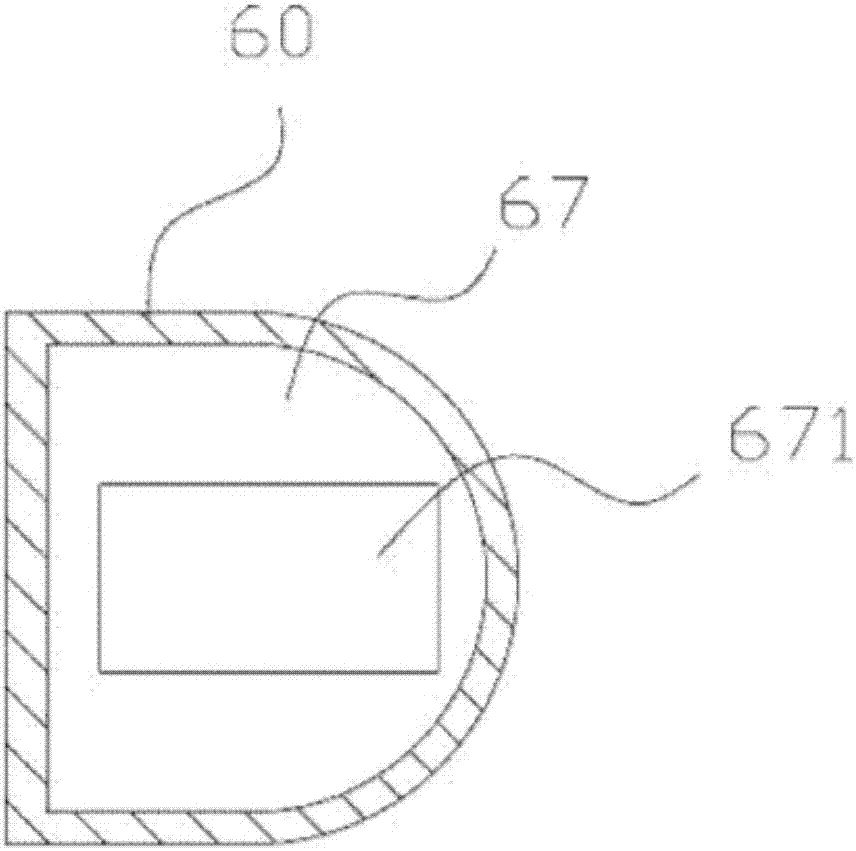

[0023] The bottom surface of the left side of the upper fixed cover 40 is fixed with a main shaft connecting sleeve 48 and a rotating main shaft 49 articulated. The rotating main shaft 49 is inserted and sleeved in the main shaft connecting sleeve 48. A gear box 481 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com