Surface forming and knurling equipment for PVB film and production technology of surface forming and knurling equipment

A technology of surface molding and production technology, which is applied to other household appliances, flat products, household appliances, etc., can solve problems such as insufficient embossing patterns, success or failure of embossing, slow production speed, etc., and achieve the effect of improving embossing quality and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

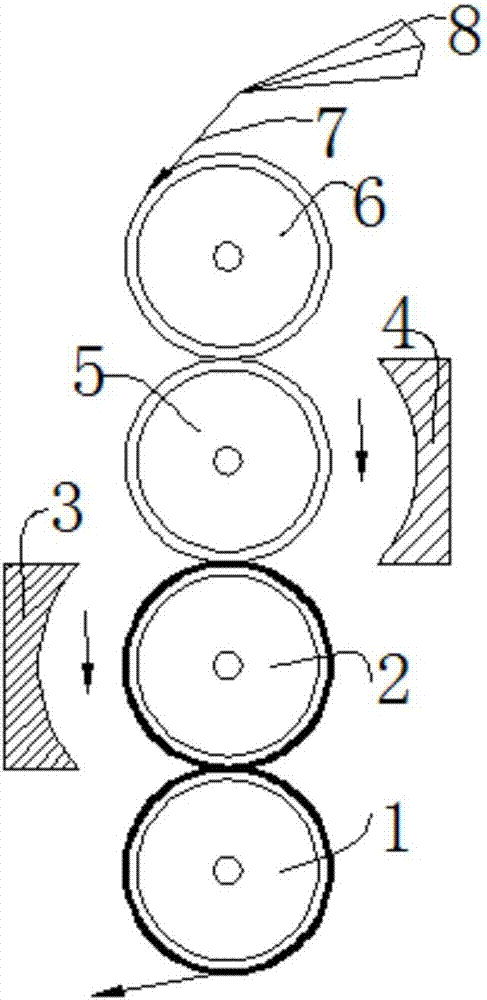

[0032] Such as figure 1 Shown: a PVB film surface forming embossing equipment, including pre-forming device, embossing device and heating device.

[0033] The preforming device comprises a rotatable main photo roll 5 and a rotatable first photo roll 6 (secondary photo roll) in contact with (tangent to) said main photo roll 5 . The main light roll 5 and the first light roll 6 are on the same end face, and the end face is perpendicular to the horizontal plane.

[0034] The heating device includes a first heating device 4 and a second heating device 3 . The first heating device 4 is located at one side of the main light roll 5 , and the second heating device 3 is located at one side of the first embossing roll 2 . It should be noted that the first heating device 4 and the second heating device 3 are not located on the same side. The first heating device 4 and the second heating device 3 can be heating sheets made based on ordinary resistance wires, or segmented heating devices...

Embodiment 2

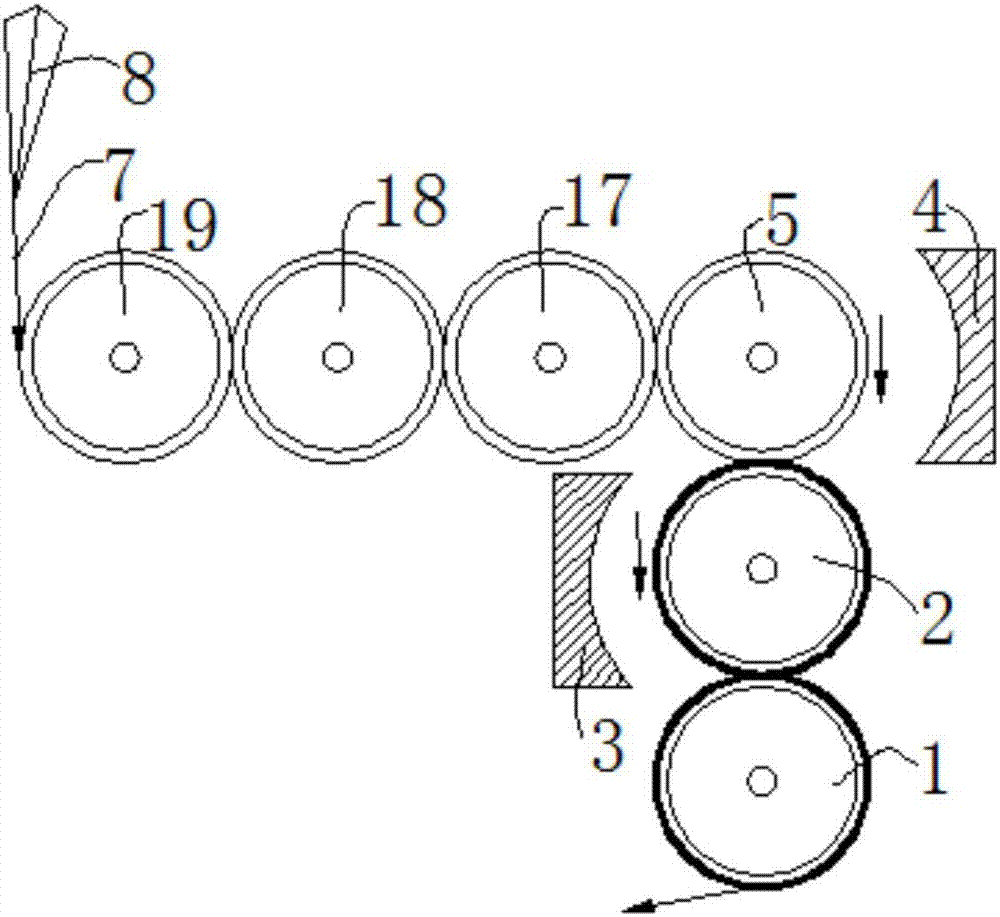

[0038] Such as figure 2 Shown: a PVB film surface forming embossing equipment, including pre-forming device, embossing device and heating device.

[0039] The preforming device includes a twelfth light roll 19, an eleventh light roll 18, a tenth light roll 17 and a master light roll which are tangent in sequence. Wherein, the main axes of the twelfth smooth roller 19 , the eleventh smooth roller 18 , the tenth smooth roller 17 and the main smooth roller 5 are located on the same horizontal plane. On the one hand, the role of the light roller is to preform the PVB film coming out of the extrusion die 8, and has a guiding effect, so that the PVB film is attached to the light roller and moves, shortening the distance of the PVB film outside.

[0040] The heating device includes a first heating device 4 and a second heating device 3 . The first heating device 4 is located at one side of the main light roll 5 , and the second heating device 3 is located at one side of the first ...

Embodiment 3

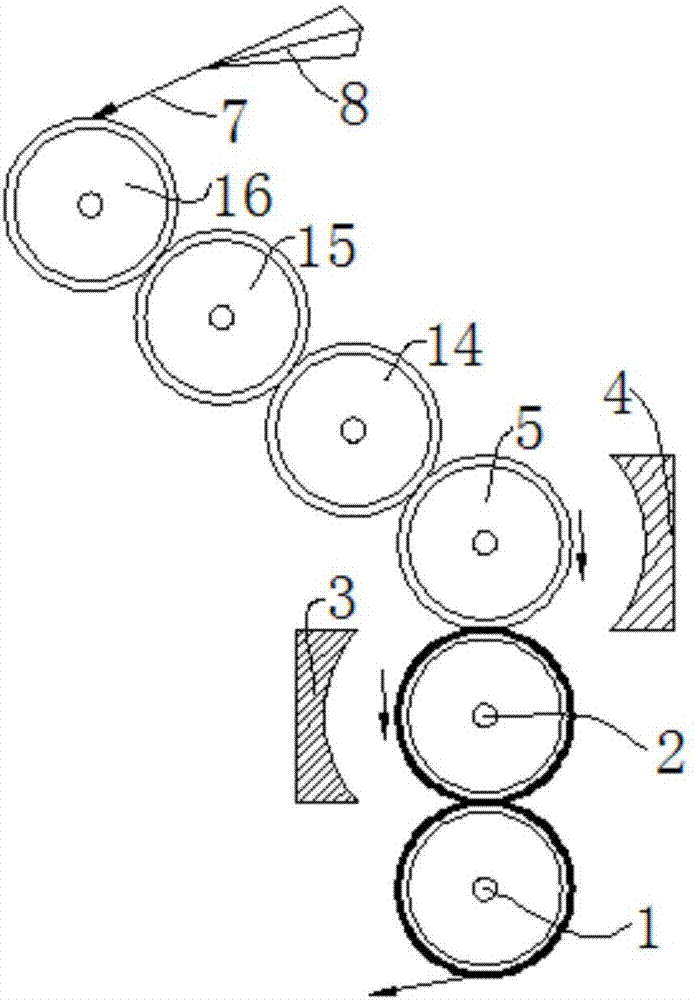

[0044] Such as image 3 Shown: a PVB film surface forming embossing equipment, including pre-forming device, embossing device and heating device.

[0045] The preforming device includes a ninth smooth roll 16 , an eighth smooth roll 15 , a seventh smooth roll 14 and a main smooth roll 5 tangentially in sequence. The axes of the ninth smooth roller 16 , the eighth smooth roller 15 , the seventh smooth roller 14 and the main smooth roller 5 are located at the same end face. The end surface has a certain angle with the horizontal plane.

[0046] The heating device includes a first heating device 4 and a second heating device 3 . The first heating device 4 is located at one side of the main light roll 5 , and the second heating device 3 is located at one side of the first embossing roll 2 . It should be noted that the first heating device 4 and the second heating device 3 are not located on the same side.

[0047] The embossing device includes a second embossing roller 1 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com