Model cooling device for 3D printing

A technology of cooling device and model, which is applied in the field of 3D printing, can solve the problems such as the inability to adjust the cooling position, and achieve the effect of simple structure, scientific and reasonable design, and flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

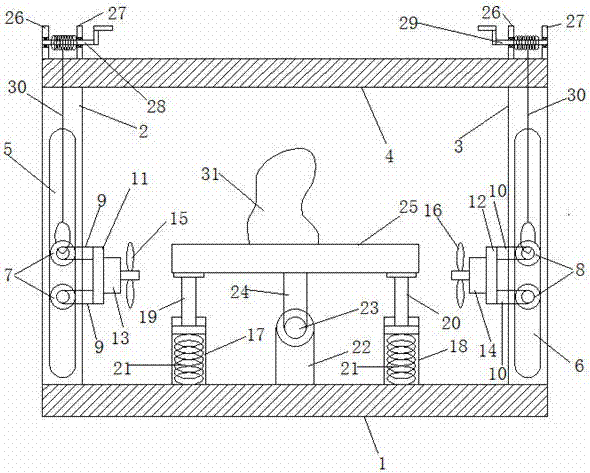

[0011] Such as figure 1 As shown, a model cooling device for 3D printing, which includes: base 1, left guide plate 2, right guide plate 3, upper support plate 4, left sliding hole 5, right sliding hole 6, left sliding wheel 7, right sliding Wheel 8, left support column 9, right support column 10, left carrier plate 11, right carrier plate 12, left cooling motor 13, right cooling motor 14, left cooling fan 15, right cooling fan 16, left shock absorber 17, righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com