Spray head switching and clearing device of 3D printer

A 3D printer and cleaning device technology, applied in coating devices, 3D object support structures, additive manufacturing, etc., can solve problems such as nozzle blockage and impact, and achieve the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

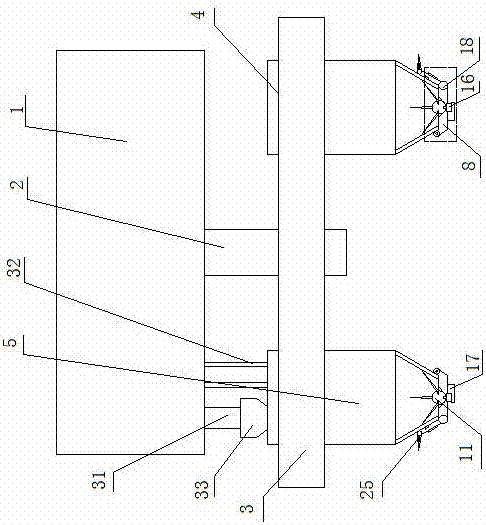

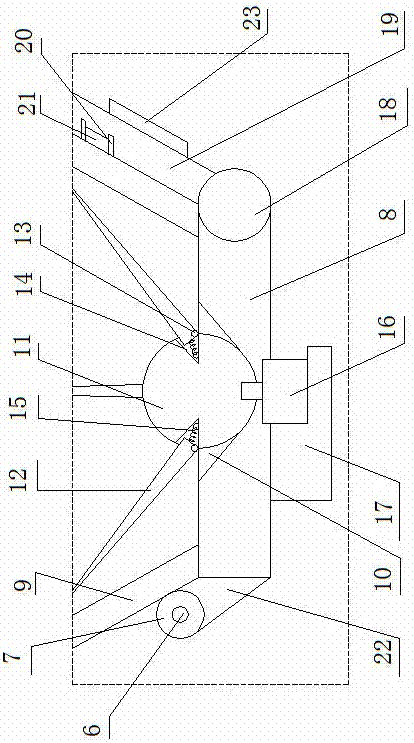

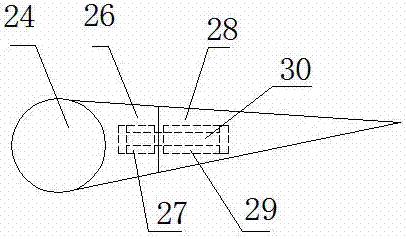

[0021] Such as figure 1 As shown, a nozzle switching and cleaning device of a 3D printer is composed of: an ink cartridge 1, a feed pipe 31, and a silk feed pipe 32, and the ink cartridge 1 protrudes from the feed pipe 31 and the silk feed Pipe 32, the feed pipe 31 is inserted into the feed hopper 33, one end of the fixed shaft I2 is set at the center of the bottom end of the ink cartridge 1, and the other end of the fixed shaft I2 is connected to the turntable 3, and the turntable 3 There are at least two circular ports 4 on the top, and an extruder 5 is installed in each of the circular ports 4, and the extruder 5 is connected to the spray head 9, and the bottom end of the spray head 9 is The surface is connected with the support plate 8 through the fixed shaft II6 and the rotating shaft sleeve 7. The upper end of the support plate 8 is provided with an arc-shaped groove 10, and the arc-shaped groove 10 is filled with a ball 11. The ball 11 Three flaps I12 with tapered cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com