Gear transmission amplified type joint shearing damper

A gear-driven, amplified technology, applied in the direction of protected buildings/shelters, building components, building types, etc., can solve problems such as limitations, relative rotation angles or small displacements, and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

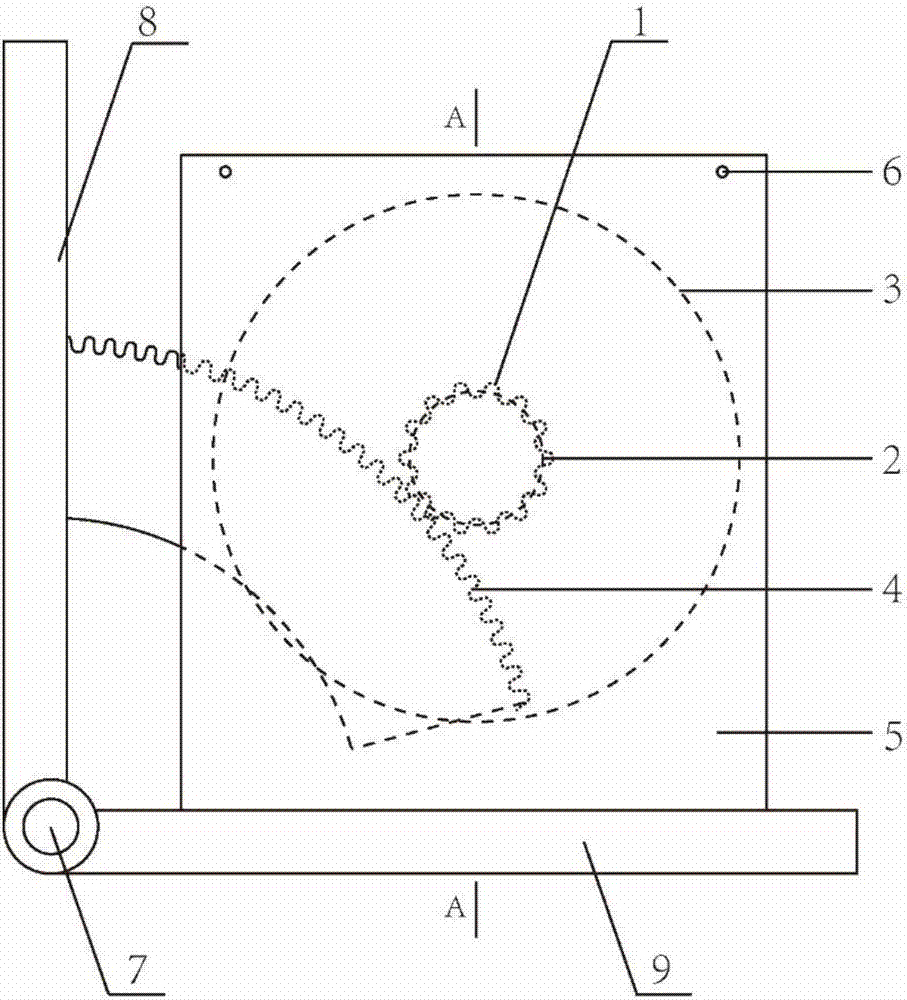

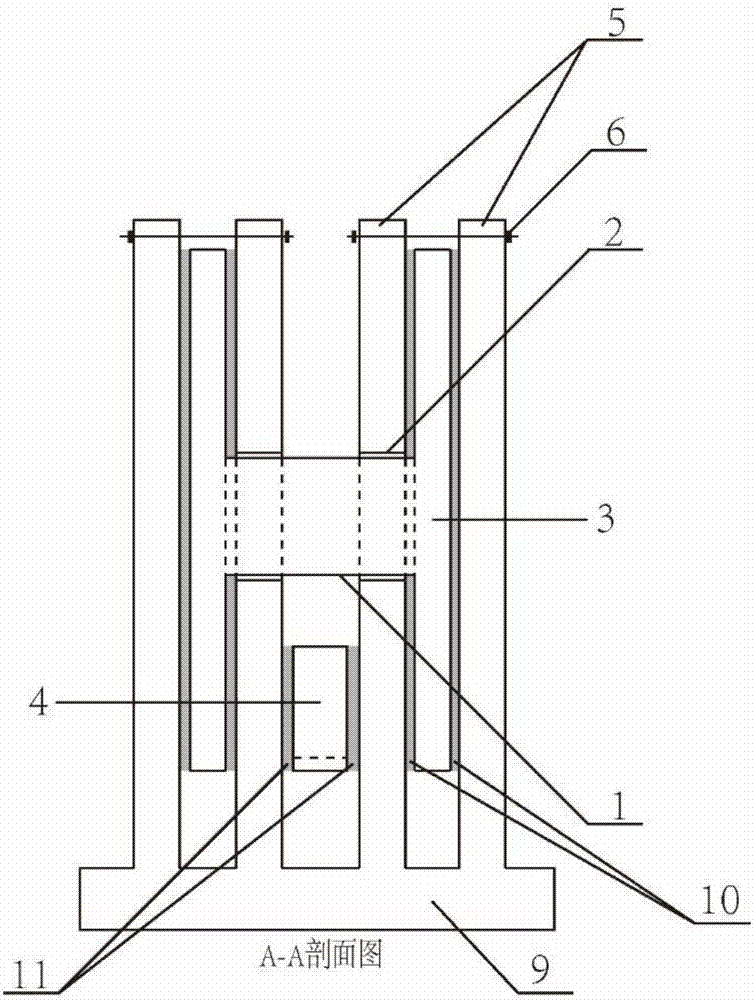

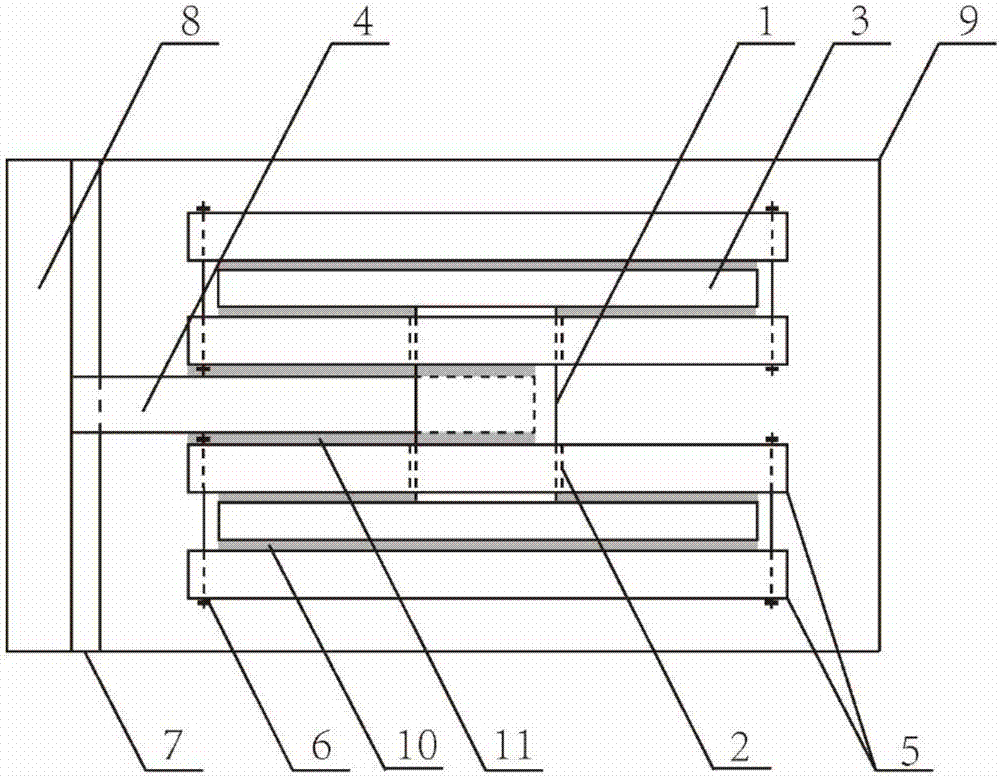

[0036] A gear transmission amplified node shear damper, including a gear 1, a circular hole 2, a turntable 3, a curved plate 4, a supporting steel plate 5, a compression bolt 6, a rotating shaft 7, a side plate 8, a bottom plate 9, a first adhesive An elastic gasket 10 and a second viscoelastic gasket 11; the main body structure of the damper is symmetrical on both sides;

[0037] The side plate 8 and the bottom plate 9 are hinged by the rotating shaft 7 to form a bracket; the curved plate 4 takes the rotating shaft 7 as the center and is vertically fixed on the center line of the side plate 8. The outer ring surface of 4 is provided with teeth that mesh with the gear, and the two form an occlusal gear mechanism; the curved plate 4 is located between two supporting steel plates 5, forming a symmetrical stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com