Supersonic spraying pipe

A supersonic and nozzle technology, applied in the direction of jet propulsion devices, machines/engines, etc., can solve the problems of high processing difficulty, total gas pressure loss, lack of economy and environmental protection, etc., and achieve production difficulty and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

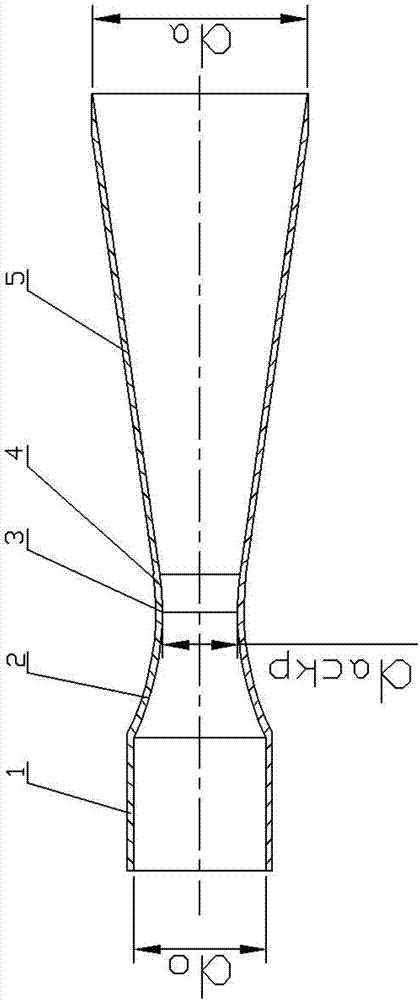

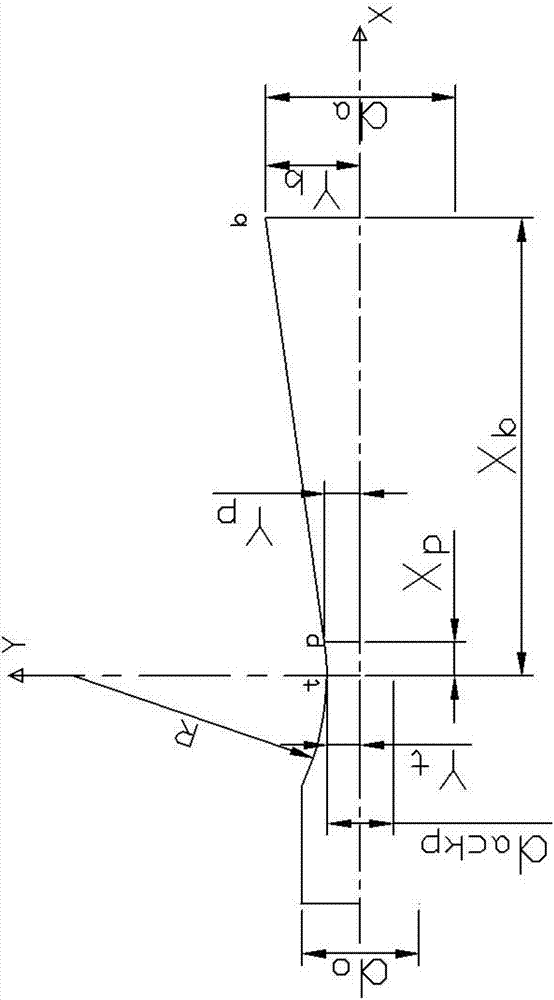

[0023] Such as Figure 1-2 As shown, a supersonic nozzle includes an inlet equal straight section 1, a subsonic convergent section 2, an initial supersonic expansion section 4 and a supersonic expansion section 5 that are fixedly connected in sequence; the inlet equal straight section 1, The subsonic convergence section 2, the initial supersonic expansion section 4 and the supersonic expansion section 5 are all hollow bodies of revolution, and the entrance is straight section 1, the subsonic convergence section 2, the initial supersonic expansion section 4 and the supersonic expansion section 5 The axis of revolution of the same; the internal flow channel of the subsonic convergence section 2 is a continuously shrinking circular arc axis of revolution, and the internal flow channel of the initial supersonic expansion section 4 is a continuously expanding circular axis surface of revolution, The internal flow channel of the supersonic expansion section 5 is a circular table sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com