Structure surface crack monitoring method based on a rotating electromagnetic field

A technology of structural surface and electromagnetic field, applied in the direction of using electromagnetic means, measuring devices, using electrical devices, etc., can solve problems such as the influence of monitoring sensitivity, increase the difficulty and cost of making monitoring probes, and difficult to accurately monitor key structural cracks in industrial equipment. The effect of reducing the difficulty and cost of production and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

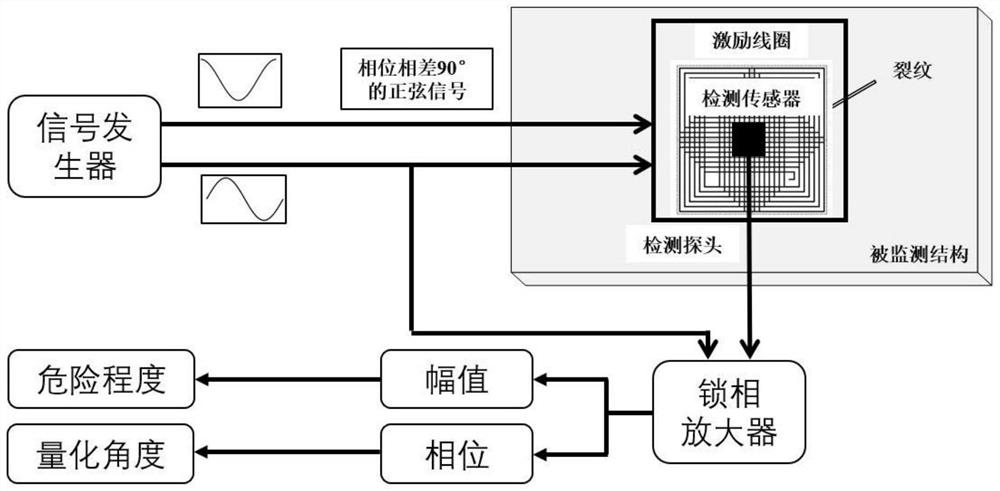

[0020] Such as figure 1 As shown, the monitoring system mainly includes a signal generator, a monitoring probe, a structure to be monitored, and a lock-in amplifier. The signal generator generates two sinusoidal signals with equal frequencies and amplitudes and initial phases of 0° and 90° respectively. The sinusoidal signals are respectively Loaded on the upper coil and the lower coil of the excitation coil, the excitation coil will induce a rotating electromagnetic field that changes periodically with time on the structure under test. Compared with the spiral induced electromagnetic field induced by conventional eddy current testing, the rotating electromagnetic field is rotating. The uniform field has the same detection sensitivity for cracks in any direction.

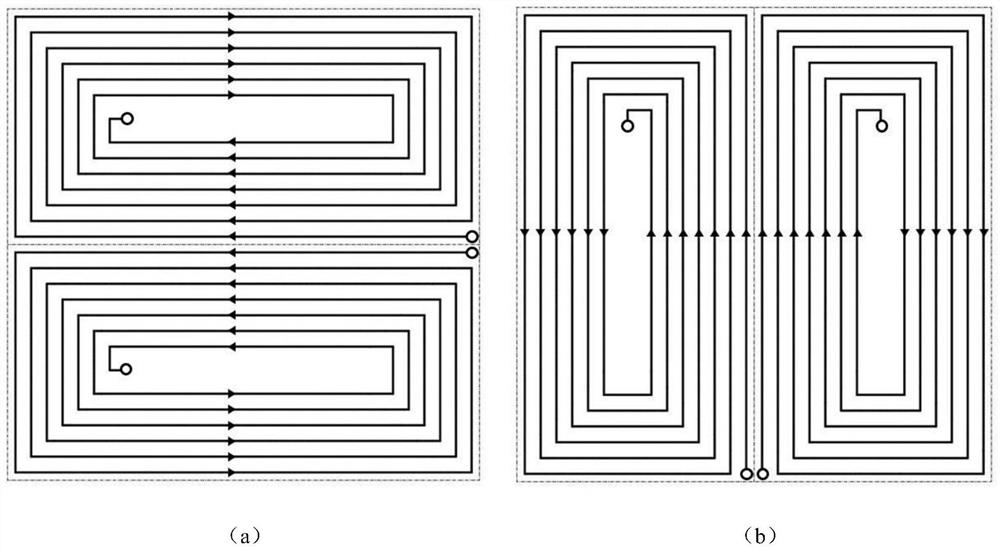

[0021] Further, such as figure 2 As shown, the upper coil and the lower coil are composed of two rectangular coils, the rectangular coils are symmetrically distributed, and the winding directions are opposite. At ...

Embodiment 2

[0023] The signal generator generates 10kHz, 2-way sinusoidal signals with 5V initial phases of 0° and 90° respectively, and the two-way sinusoidal signals are respectively loaded on the upper coil and the lower coil of the excitation coil, and the excitation coil induces the space in the measured structure. The induced electromagnetic field rotates periodically with time. When there is a crack, the induced electromagnetic field will be disturbed. The magnetic field sensor is located at the center of the excitation coil. The magnetic field sensor will pick up the magnetic field perpendicular to the surface of the measured structure, and then convert it into Electrical signal Bz. The sinusoidal signal with an initial phase of 0° is used as a reference signal, and Bz is used as an input signal for lock-in amplification processing, and the amplitude of Bz is F=50mV and the phase P=136°.

[0024] Further, before the formal monitoring, the position without defect is monitored, and ...

Embodiment 3

[0027] According to the steps of the second implementation case, according to the requirements of structural safety inspection, the monitoring system can be operated all the time to monitor the key positions of the tested structure in real time, or it can be monitored according to the detection cycle of industrial equipment, and the monitoring system can be operated at regular intervals. Collect crack information at key locations of the tested structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com