Internal water pressure loading device for water tunnel structure model test

A model test, tunnel structure technology, applied in the direction of measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve the problems of sewage overflow pollution, no deep tunnel drainage works, flood disasters, etc., to ensure The effect of construction and operation safety, small error and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

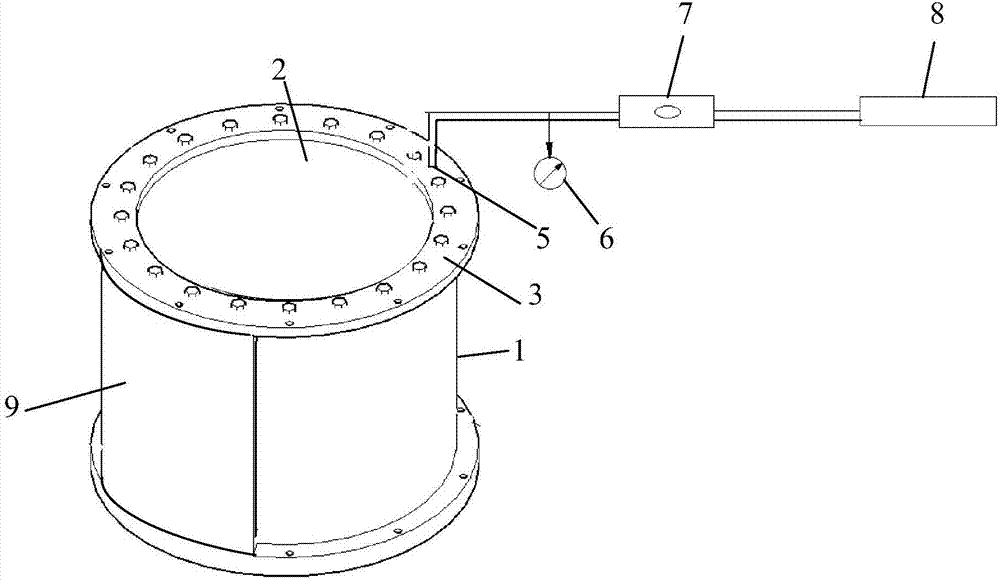

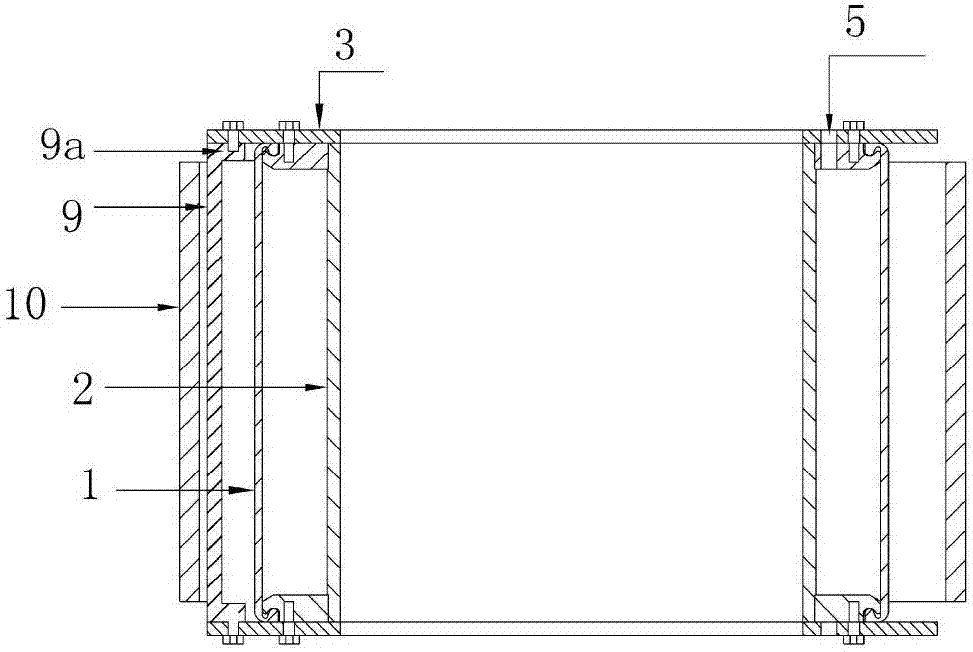

[0019] Figure 1-2 It is shown that a specific embodiment of the present invention is an internal water pressure loading device used for the structural model test of a water conveyance tunnel, comprising two parts: a rubber air bag pressurizing device and an air supply and pressure maintaining device, in which:

[0020] The rubber airbag pressurizing device is composed of: an outer rubber wall 1, an inner stainless steel wall 2, and a stainless steel flange ring 3 at the upper and lower ends to form a circular cylindrical airbag; the stainless steel flange An air hole 5 is provided on the ring 3;

[0021] The composition of the gas supply and pressure holding device is: CO 2 The gas source 8, the three-position rotary valve 7, the barometer 6, and the gas hole 5 are connected in sequence by a gas pipe.

[0022] The outer edge of the stainless steel flange ring 3 in this example protrudes from the outer surface of the rubber wall 1. The upper and lower sides of the stainless steel ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com