Efficient paint blending device

A paint and blending technology, used in transportation and packaging, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of uneven stirring force, cumbersome operation process, paint splashing outside, etc., to reduce operation. Steps, reduce paint waste, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

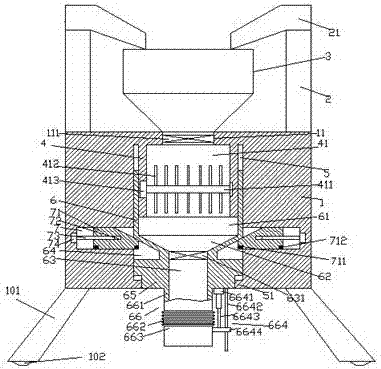

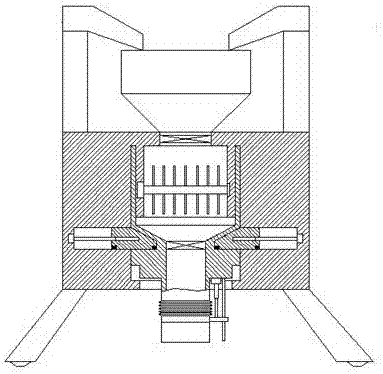

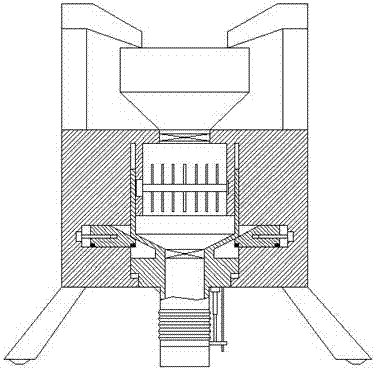

[0023] Such as Figure 1-Figure 5 As shown, an efficient paint blending device of the present invention includes a box 1 and a bucket 3 fixedly arranged on the top of the box 1, and the top of the box 1 on the left and right sides of the bucket 3 is fixedly arranged There is a support rod 2, and the top of the support rod 2 is provided with a feeding part 21, and the inside of the feeding part 21 is extended to the top of the bucket 3, and the box 1 is provided with a first cavity 5 , the bottom edge of the first cavity 5 is provided with a protruding ring 51, and the inner walls of the left and right sides close to the bottom of the first cavity 5 are correspondingly provided with sliding grooves 7, and sliding grooves 7 are provided in the first cavity 5. The sliding part 6 that is matched and connected, the top of the sliding part 6 is provided with a second cavity 61, and the top of the second cavity 61 is slid and connected with a connecting sleeve 4, and the top of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com