Sagger interior sweeping machine

A sweeper and saggar technology, applied in the direction of removing smoke and dust, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problem that materials cannot be completely removed, and achieve the effect of improving material recovery rate and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

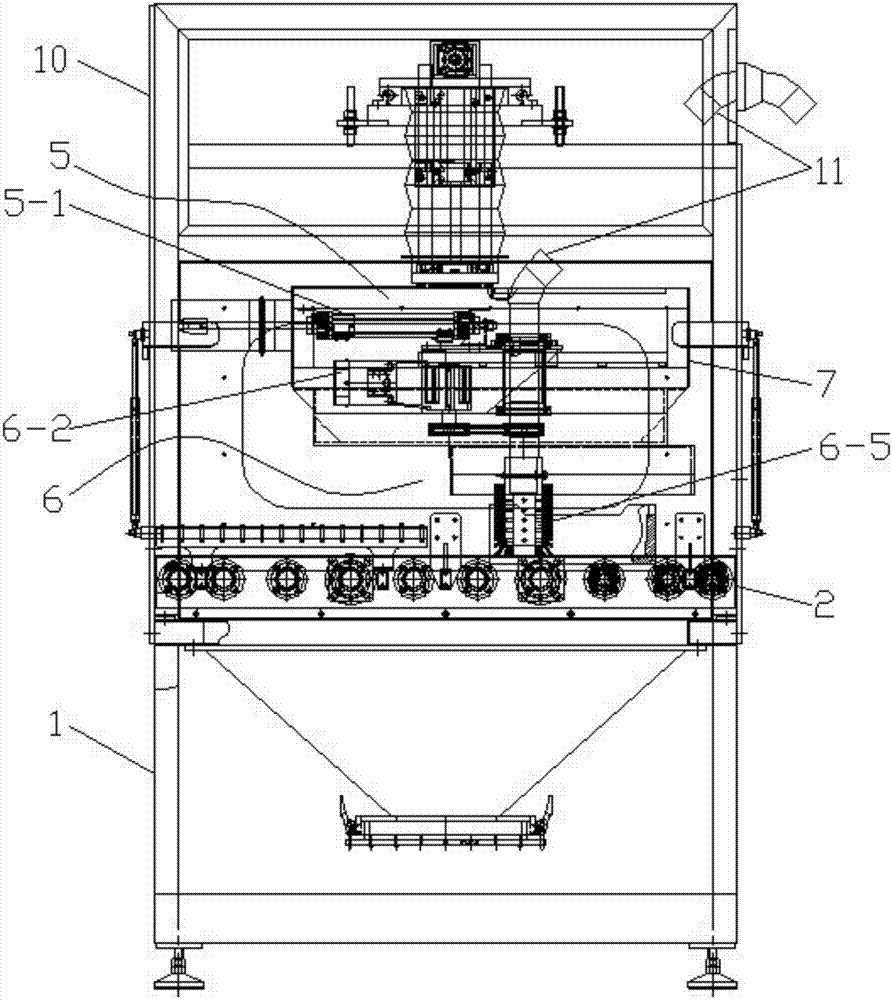

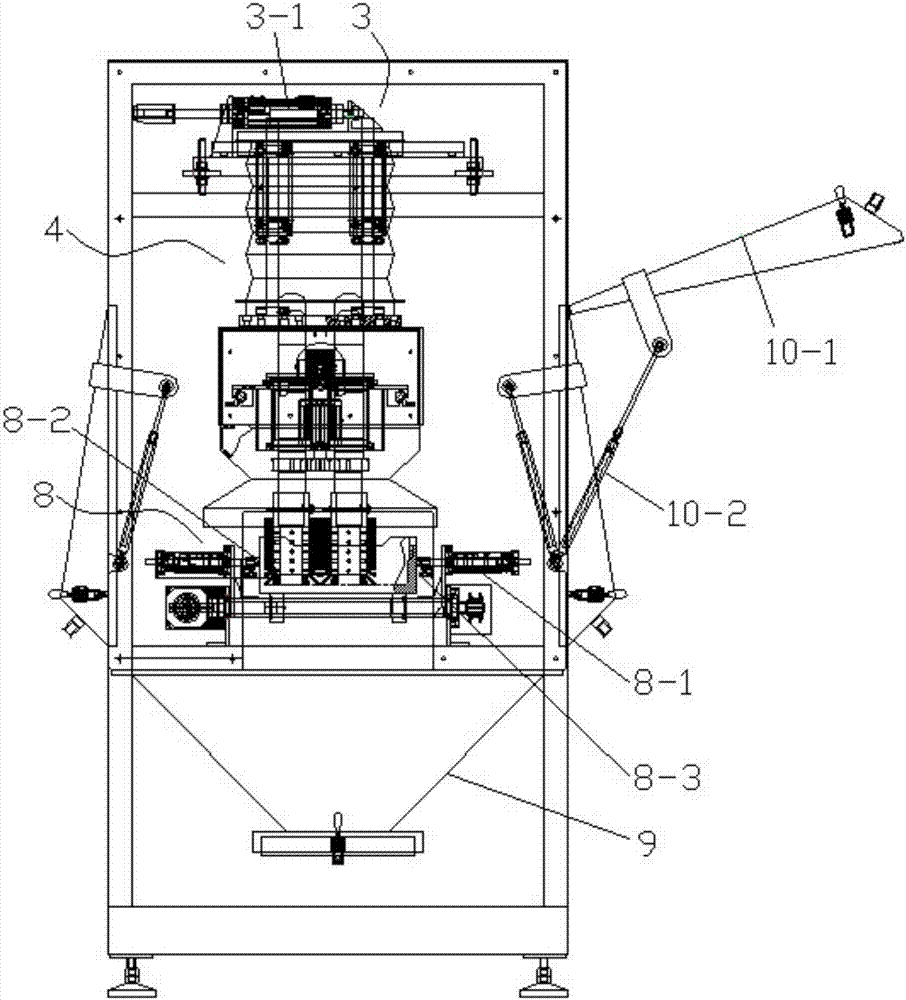

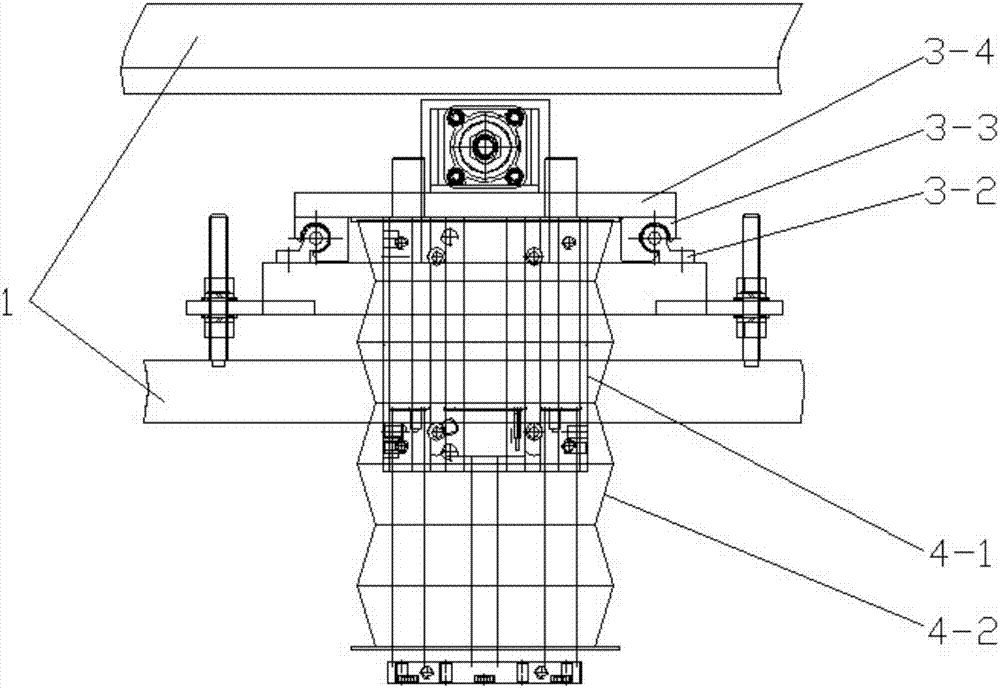

[0035] The invention discloses a cleaning machine inside a sagger, such as Figure 1-6 As shown, it includes a support 1, a transport line 2, a front and rear travel unit 3, a lifting device 4, a left and right travel unit 5, a self-rotating electric brush unit 6, a brush unit mounting seat 7 and a bowl clamping device 8. The front and rear travel units, the lifting device and the left and right travel units each include a fixed part and a movable part, and the fixed part and the movable part can be relatively translated. The fixed part and the movable part are relative concepts, one is the fixed part and the other is the movable part. The front and rear traveling units are installed on the upper part of the support, and the lifting device is installed on the movable part of the front and rear traveling units and extends downwards, and moves forward and backward driven by the front and rear traveling units. The brush unit installation seat is fixed on the lower part of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com