A station adjustable fixture device for imprinting T-joint workpieces

A fixture device and station technology, applied in the field of station-adjustable fixture devices, can solve problems such as inaccurate experimental data and position deviation of embossed points, and achieve the effects of avoiding manual support, avoiding errors, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

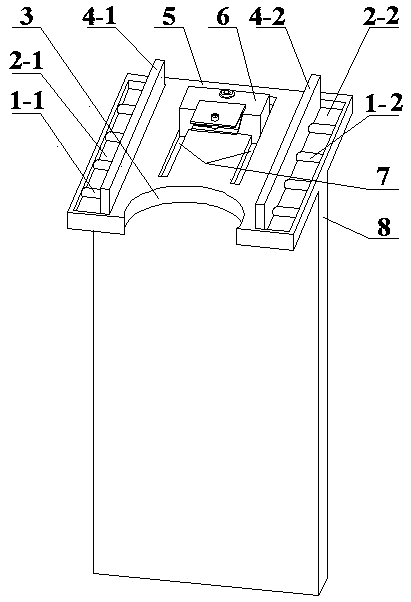

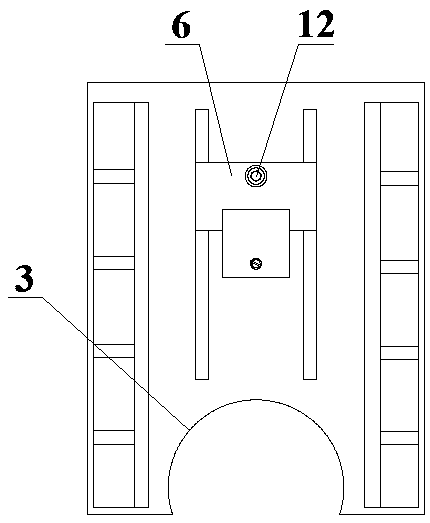

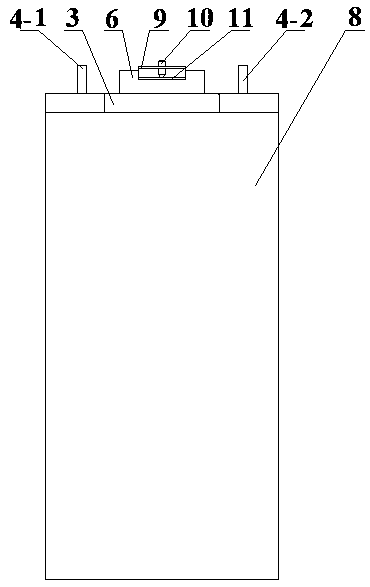

[0021] Embodiment 1: as Figure 1-5 As shown, a position-adjustable fixture device for embossing T-shaped joint workpieces, including spring group Ⅰ1-1, spring group Ⅱ1-2, centering plate groove Ⅰ2-1, centering plate groove Ⅱ2-2, ring Set 3, centering plate Ⅰ4-1, centering plate Ⅱ4-2, clamp body 5, positioning block 6, baffle groove 7, vertical plate 8, upper pressing plate 9, adjusting screw 10, lower pressing plate 11, fastening screw 12 and graduated scale 13;

[0022] The vertical plate 8 is connected to the lower end of the fixture main body 5, the centering plate groove I2-1 and the centering plate groove II2-2 are respectively milled on both sides of the upper end of the fixture main body 5, and the baffle plate groove 7 is milled out in the middle of the upper end of the fixture main body 5, The front end of the clamp body 5 is provided with a ring sleeve 3, the spring group I1-1 is located in the centering plate groove I2-1, the spring group II1-2 is located in the c...

Embodiment 2

[0035] Embodiment 2: as Figure 1-5 As shown, a position-adjustable fixture device for embossing T-shaped joint workpieces, including spring group Ⅰ1-1, spring group Ⅱ1-2, centering plate groove Ⅰ2-1, centering plate groove Ⅱ2-2, ring Set 3, centering plate Ⅰ4-1, centering plate Ⅱ4-2, clamp body 5, positioning block 6, baffle groove 7, vertical plate 8, upper pressing plate 9, adjusting screw 10, lower pressing plate 11, fastening screw 12 and graduated scale 13;

[0036] The vertical plate 8 is connected to the lower end of the fixture main body 5, the centering plate groove I2-1 and the centering plate groove II2-2 are respectively milled on both sides of the upper end of the fixture main body 5, and the baffle plate groove 7 is milled out in the middle of the upper end of the fixture main body 5, The front end of the clamp body 5 is provided with a ring sleeve 3, the spring group I1-1 is located in the centering plate groove I2-1, the spring group II1-2 is located in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com