Locking valve

A valve and valve switch technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as affecting valve service life, causing accidents, and adverse valve protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

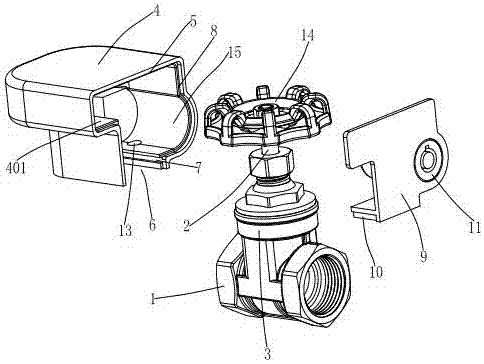

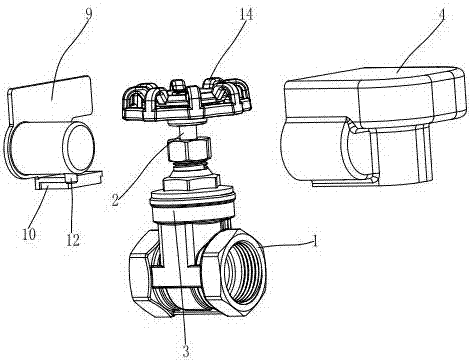

[0016] Example 1, please refer to figure 1 , figure 2 , the present invention provides a locking valve disclosed by the present invention, comprising a valve body 1, an opening and closing member disposed in the valve body 1, and a valve stem 2 connected with the opening and closing member. The valve body 1 is provided with a middle hole 3, One end of the valve stem 2 runs through the middle hole 3 and is connected with a valve switch. The valve body 1 is covered with a protective cover 4, and one side of the protective cover 4 is provided with an opening 5. One end of the valve stem 2 is located in the protective cover 4; the bottom of the protective cover 4 is provided with a U-shaped mouth 6; the two sides of the U-shaped mouth 6 are provided with mutually symmetrical slideways 7; the opening 5 is provided with a mounting Step 8; the installation step 8 is covered with a cover plate 9, and the cover plate 9 covers and closes the opening 5; the bottom of the cover plate 9 ...

Embodiment 2

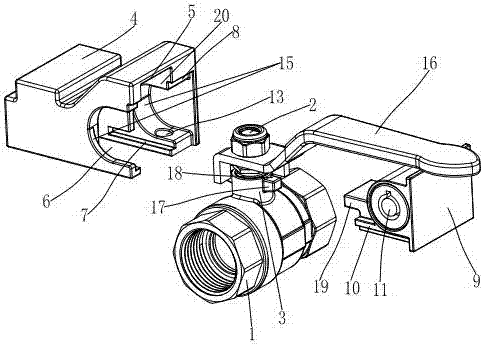

[0022] Example 2, see image 3 , Figure 4 , the present invention discloses a locking valve, comprising a valve body 1, an opening and closing member arranged in the valve body 1, and a valve stem 2 connected with the opening and closing member. The valve body 1 is provided with a middle hole 3, and the valve stem 2 One end goes through the middle hole 3 and is connected with a valve switch. The valve body 1 is covered with a protective cover 4, and one side of the protective cover 4 has an opening 5. The valve switch, the middle hole 3, and the valve stem 2 passing through the middle hole 3 One end is located in the protective cover 4; the bottom of the protective cover 4 is provided with a U-shaped mouth 6; the two sides of the U-shaped mouth 6 are provided with mutually symmetrical slideways 7; the opening 5 is provided with a mounting step 8; The installation step 8 is covered with a cover plate 9, and the cover plate 9 closes the opening 5; the bottom of the cover plate...

Embodiment 2

[0025] The usage method of embodiment two is as follows:

[0026] When the valve needs to be used, the lock body 11 can be rotated by a key so that the lock core 12 is retracted toward the lock body 11. At this time, the lock core 12 is separated from the lock hole 13, and there is no gap between the protective cover 4 and the cover plate 9. Then connect, the staff can remove the cover plate 9 from the installation step 8 of the protective cover 4 by external force, so that the cover plate 9 is separated from the protective cover 4, and after the protective cover 4 loses the restriction of the cover plate 9, the protective cover 4 can pass through. The opening 5 and the U-shaped port 6 slide out from the valve body 1 to separate from it, and then the handle 16 can be rotated according to actual needs.

[0027]When the valve needs to be protected again after the rotation of the handle 16 is completed, the staff can hold the protective cover 4 and move the opening 5 of the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com