Ballast tank water taking device and applications thereof

A water intake device and ballast tank technology, applied in the field of ships, can solve problems such as difficulty in opening the cover to take water, and the inability to open the cover for sampling, etc., and achieve the effects of saving manpower and material resources, preventing water leakage, and simplifying the operation of water intake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

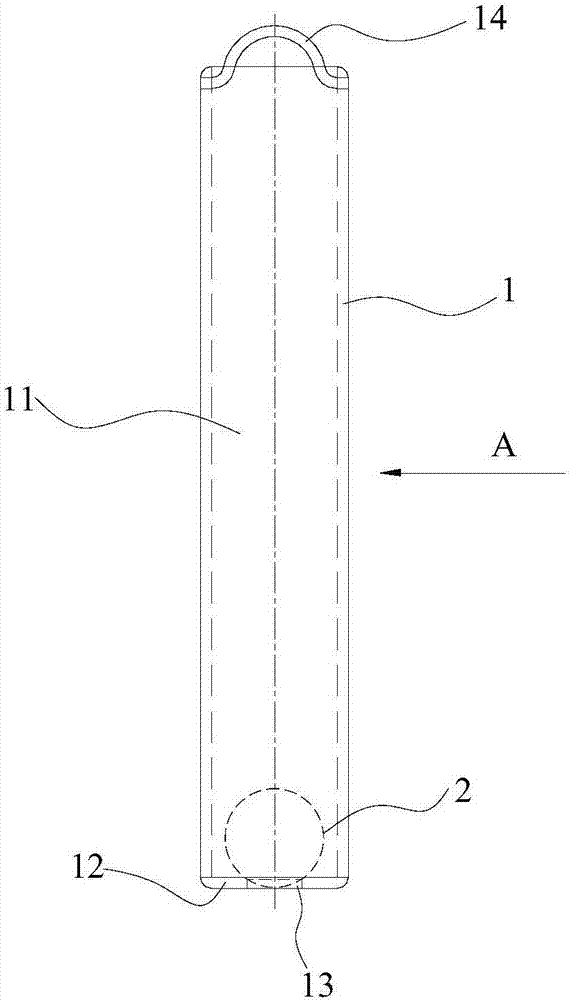

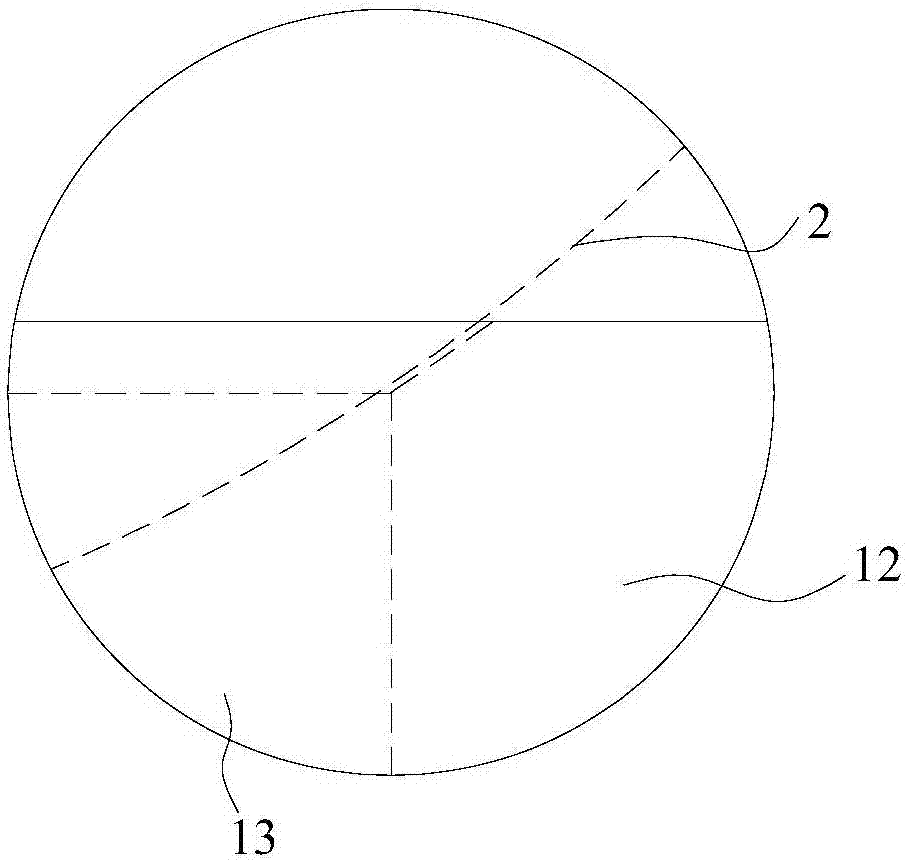

[0039] Such as figure 1 As shown, the ballast tank water intake device in this embodiment includes: a water intake device body 1, which has a hollow structure housing chamber 11 inside, and is provided with the housing chamber 1 on the water intake device body 1. 11 is connected to the water inlet hole 13; the blocking member 2, the blocking member 2 is arranged in the accommodating chamber 11, and is used to selectively block the water inlet hole 13: when the accommodating chamber 11 needs to enter When there is water, the water inlet hole 13 is opened, and the accommodating chamber 11 communicates with the outside through the water inlet hole 13. When the accommodating chamber 11 is full of water, the blocking member 2 blocks the water hole13.

[0040] Wherein, the water intake device body 1 is made of stainless steel pipe.

[0041] In this embodiment, a water intake hole 13 is provided on the water intake device body 1, and a blocking member 2 for selectively blocking the...

Embodiment 2

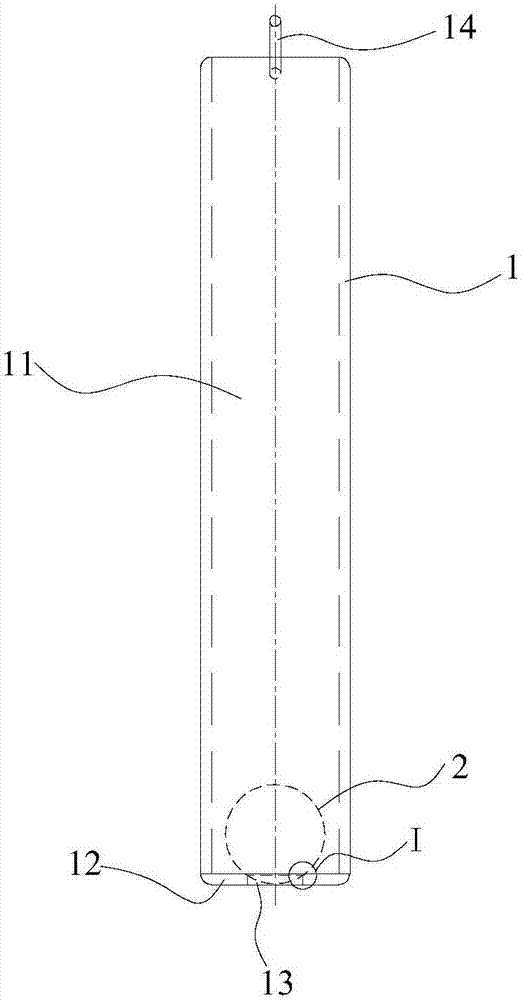

[0054] The part of the ballast tank water intake device in this embodiment follows the reference numerals in the first embodiment.

[0055] In this embodiment, the water intake device for the ballast tank includes: a water intake device body 1 having a hollow housing cavity 11 inside the water intake device body 1, and a hole communicating with the housing cavity 11 is opened on the water intake device body 1 The water inlet hole 13; the blocking member 2, the blocking member 2 is arranged in the accommodating chamber 11 to selectively block the water inlet hole 13: when the accommodating chamber 11 needs to enter water, The water inlet hole 13 is opened, and the accommodating chamber 11 communicates with the outside through the water inlet hole 13. When the accommodating chamber 11 is full of water, the blocking member 2 blocks the water inlet hole 13 .

[0056] In this embodiment, a water intake hole 13 is provided on the water intake device body 1, and a blocking member 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com